Home » Cutting Packaging Costs Without Sacrificing Protection

Cutting Packaging Costs Without Sacrificing Protection

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated customers. The key is balancing material use, box design, and supply chain efficiency so that savings do not come at the expense of protection.

Where Packaging Costs Add Up

- Oversized boxes: Drive dimensional weight charges.

- Excess materials: Overuse of void fill and inserts.

- Complex SKU mix: Redundant sizes increase inventory costs.

- Inefficient freight: Poor palletization and stacking.

Cost-Saving Strategies That Maintain Protection

- Right-sizing: Match box size to product dimensions to cut DIM charges and material use.

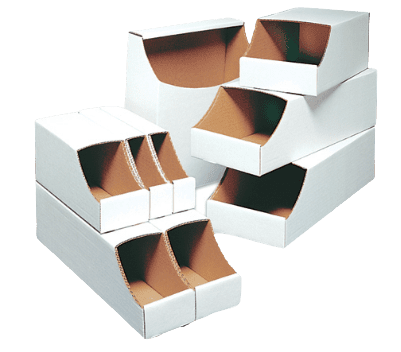

- Optimize corrugated grades: Switch to single- or double-wall where appropriate without compromising strength.

- Consolidate SKUs: Streamline packaging options to reduce inventory overhead.

- Efficient inserts: Replace foam or excess dunnage with engineered corrugated or molded pulp.

- Supplier contracts: Negotiate based on annual volumes, not just peak season orders.

Testing Before Implementing Changes

- Use ASTM and ISTA protocols to ensure changes won’t increase product damage.

- Test for compression, vibration, and drop resistance.

- Run pilot shipments before scaling across the supply chain.

Balancing Sustainability and Cost

Eco-friendly doesn’t have to mean expensive:

- Use recyclable coatings to reduce plastic films.

- Choose corrugated designs that require less material while maintaining stacking strength.

- Highlight sustainable solutions in marketing to offset cost concerns.

Packaging Solutions with Brown Packaging

Brown Packaging helps companies lower costs while protecting products across the supply chain. From SKU rationalization to right-sized corrugated solutions, our team ensures packaging savings don’t compromise performance. Contact us to optimize your packaging program.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.

Sustainable Packaging Coalition. (2023). Packaging Efficiency and Waste Reduction Report. Retrieved from https://sustainablepackaging.org

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are learning that premium doesn’t always

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of actual or dimensional weight, which

Home » Cutting Packaging Costs Without Sacrificing Protection