Home » Customizing Edge Protectors to Your Specific Packaging Needs: A Step-by-step Guide

Customizing Edge Protectors to Your Specific Packaging Needs: A Step-by-step Guide

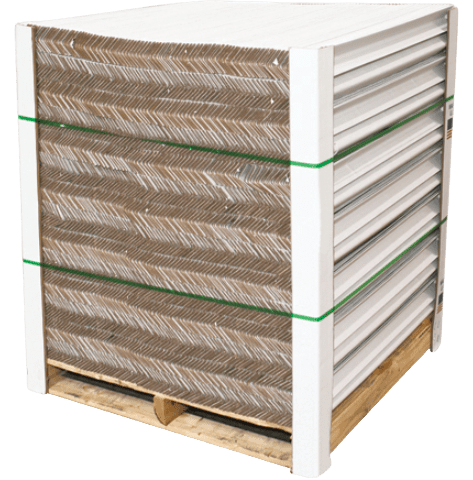

When it comes to packaging fragile or valuable items, ensuring their safe transportation is crucial. One effective way to protect these items during shipping or storage is by using edge protectors. Edge protectors are versatile packaging materials designed to safeguard the edges of products and prevent damage caused by impact, compression, or rough handling. While standard edge protectors are readily available, customizing them to suit your specific packaging needs can provide added protection and peace of mind. In this step-by-step guide, we will walk you through the process of customizing edge protectors for your unique requirements.

Step 1: Assess Your Packaging Requirements

Before customizing edge protectors, it’s essential to assess your packaging requirements thoroughly. Consider the size, shape, and fragility of the items you are packaging. Identify potential vulnerabilities, such as sharp corners or delicate surfaces that require extra protection. Additionally, determine the transportation or storage conditions your packages will be subjected to. By understanding your specific needs, you can tailor your edge protectors accordingly.

Step 2: Select the Appropriate Edge Protector Material

Edge protectors are available in various materials, each offering distinct benefits. Common materials include cardboard, foam, plastic, and composite materials. Cardboard edge protectors are ideal for light to medium-duty applications, while foam edge protectors offer excellent cushioning and shock absorption. Plastic edge protectors are durable and water-resistant, making them suitable for heavy-duty applications. Composite edge protectors combine multiple materials for enhanced protection. Choose the material that best aligns with your requirements.

Step 3: Measure and Cut

Once you’ve determined the material, it’s time to measure and cut the edge protectors to the desired length. Measure the dimensions of your item’s edges and add a few extra inches for overlap. This overlap will ensure complete edge coverage and optimal protection. Use a ruler or measuring tape to achieve accurate measurements. Then, using a sharp utility knife or scissors, carefully cut the edge protectors along the measured lines, unless they are custom made to the exact size.

Step 4: Shape the Edge Protectors

Depending on your packaging needs, you may need to shape the edge protectors to fit specific corners or edges. For example, if your item has rounded edges, you can create a curved shape in the foam edge protectors to provide a snug fit. Use a utility knife or scissors to make precise cuts and adjustments, ensuring a tailored fit for maximum protection.

Step 5: Add Reinforcements (Optional)

For particularly fragile or heavy items, you may consider reinforcing the edge protectors for added strength. Reinforcements can be achieved by layering multiple edge protectors together or by attaching additional support materials, such as adhesive foam pads or corner guards. Reinforcing the edge protectors will help distribute the impact and protect your items from potential damage.

Step 6: Secure the Edge Protectors

After customizing the edge protectors to fit your specific packaging needs, it’s time to secure them in place. Depending on the material and design of the edge protectors, there are several options for attachment. Adhesive backing, double-sided tape, or straps can be used to secure the edge protectors to the edges or corners of your item. Ensure that the edge protectors are firmly and evenly attached, leaving no gaps or loose ends.

Step 7: Test for Adequate Protection

Before finalizing your customized edge protectors, perform a thorough testing process to ensure they provide adequate protection. Mimic the transportation or storage conditions your packages will undergo, subjecting them to simulated impacts or rough handling. Inspect the packaged item for any signs of vulnerability or damage. If needed, make further adjustments to the edge protectors to enhance their protective capabilities.

Step 8: Regularly Evaluate and Improve

Packaging needs and requirements may evolve over time, so it’s crucial to regularly evaluate and improve your customized edge protectors. Stay updated with industry advancements and new packaging technologies that can enhance protection. Solicit feedback from your shipping or warehousing team and customers to identify areas for improvement. By continuously evaluating and refining your customized edge protectors, you can ensure the highest level of protection for your valuable items.

If interested in custom edge protectors, then partner with Brown Packaging today.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Customizing Edge Protectors to Your Specific Packaging Needs: A Step-by-step Guide

Polyvinyl chloride, commonly known as PVC, is a widely used plastic in the packaging industry, celebrated for its versatility and durability. PVC’s unique properties make

Packaging plays a crucial role in safeguarding products from various hazards that can compromise their quality, safety, and integrity. From the manufacturing floor to the

Polyethylene terephthalate, commonly abbreviated, stands out in the packaging industry for its versatility and environmental friendliness. Recognized as the most widely recycled plastic worldwide, this