Home » Custom Packaging: Everything You Need to Know and More

Custom Packaging: Everything You Need to Know and More

Custom packaging is the process of creating unique and personalized packaging materials tailored to the specific requirements of a product, brand, or business. In today’s crowded marketplace, custom packaging plays a crucial role in enhancing the overall customer experience, promoting brand recognition, and setting businesses apart from their competitors. In this blog, we will delve deeper into custom packaging, explore its benefits, types, considerations, and additional information that businesses need to know to make informed decisions about their packaging needs.

Why Custom Packaging is Important?

Custom packaging provides businesses with numerous benefits, such as improved brand identity, product protection, marketing, and sustainability. Custom packaging is essential for businesses because it:

- Enhances Brand Identity: Custom packaging allows businesses to create packaging designs that align with their brand identity, values, and messaging. By creating unique and consistent packaging, businesses can create a lasting impression on their customers and set themselves apart from their competitors.

- Ensures Product Protection: Custom packaging is designed to protect the product during transportation and storage. Custom packaging ensures that the product arrives at the customer’s doorstep in perfect condition, leading to customer satisfaction and loyalty.

- Improves Marketing Efforts: Custom packaging can be used as a marketing tool to promote the brand, communicate product information, and increase customer engagement. Custom packaging creates a memorable experience for customers, making it an effective way to communicate brand values and messaging.

- Supports Sustainability Efforts: Custom packaging allows businesses to choose eco-friendly materials, reduce waste, and promote their commitment to sustainability. In today’s world, customers are environmentally conscious, making sustainability an important factor for businesses to consider.

Types of Custom Packaging

Businesses have numerous options when it comes to custom packaging. Depending on the product and business requirements, there are different types of custom packaging solutions available. Some popular types of custom packaging are:

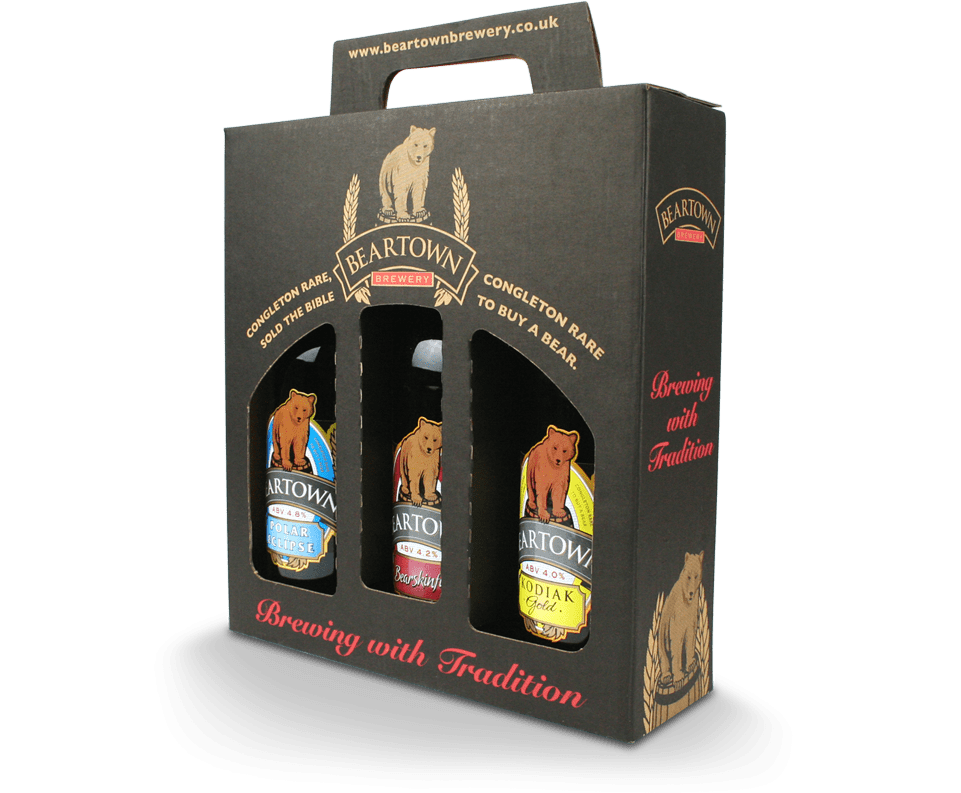

Printed Boxes

Printed boxes are a cost-effective and customizable packaging solution for various products, including food, cosmetics, and electronics. They can be customized with various printing options, including logos, images, and product information. Printed boxes come in different sizes, shapes, and materials (chipboard, paperboard and corrugated), making them versatile and suitable for different products.

Custom Bags

Custom bags are an excellent packaging option for retail businesses, restaurants, and food delivery services. They can be made from different materials, including paper, plastic, and fabric, and customized with branding and design elements. Custom bags are easy to carry, lightweight, and convenient for customers, making them a popular choice for businesses.

Custom Labels

Custom labels are an essential component of custom packaging and can be used to display product information, branding, and marketing messages. They can be made from various materials, including paper, vinyl, and polyester, and come in different sizes, shapes, and finishes. Custom labels can be applied to different packaging materials, including boxes, bags, and jars.

Custom Inserts

Custom inserts are designed to protect and secure the product inside the packaging. They can be made from different materials, including foam, corrugated, plastic and molded pulp, and customized to fit the product’s dimensions. Custom inserts ensure that the product is safe and secure during transportation, reducing the risk of damage.

Custom Tubes

Custom tubes are a popular packaging option for products such as cosmetics, pharmaceuticals, and food items. They can be made from various materials, including paper, plastic, and metal, and customized with different printing options. Custom tubes are durable, convenient, and easy to use, making them a preferred choice for many businesses.

Considerations for Custom Packaging

When designing custom packaging, businesses need to consider various factors, such as product requirements, budget, materials, design, and sustainability. By taking these factors into account, businesses can create custom packaging solutions that align with their values, meet their specific requirements, and promote their brand identity effectively. Some additional considerations for custom packaging are:

Product Compatibility

The packaging material should be compatible with the product it is intended to protect. Businesses need to consider factors such as product fragility, moisture resistance, and temperature control to ensure that the packaging material is suitable for the product.

Packaging Size

The packaging size should be appropriate for the product, ensuring that it is neither too loose nor too tight. A packaging size that is too small can damage the product, while a packaging size that is too large can lead to unnecessary material waste.

Budget and Cost-Effectiveness

Custom packaging can be expensive, and businesses need to determine their budget and cost-effectiveness of the packaging solution. It is essential to strike a balance between cost and quality to ensure that the custom packaging solution meets the business’s specific requirements and is cost-effective.

Materials

The materials used for custom packaging should be eco-friendly, sustainable, and aligned with the business’s values and messaging. Businesses should consider materials such as recycled paper, biodegradable plastics, and natural fibers to promote sustainability and environmental consciousness.

Design and Branding

The packaging design should be visually appealing, consistent with the brand identity, and convey the product information and marketing messages effectively. Custom packaging design should be eye-catching and memorable, ensuring that the packaging creates a lasting impression on customers.

Custom Packaging Regulations

Businesses should be aware of the regulatory requirements for custom packaging, such as food safety regulations, labeling requirements, and environmental regulations. Compliance with these regulations ensures that the custom packaging solution is safe, legally compliant, and sustainable.

Impact on Customer Experience

Custom packaging plays a significant role in enhancing the overall customer experience. Businesses should consider how their custom packaging solutions impact the customer experience, such as how easy it is to open, how the packaging feels in the hands, and how well it protects the product.

Logistics and Transportation

Businesses should consider the logistics and transportation requirements of their custom packaging solutions. Factors such as packaging weight, dimensions, and materials can impact shipping costs, transportation logistics, and storage.

Summary: Custom Packaging

In conclusion, custom packaging is a valuable investment that can enhance the overall customer experience, promote brand recognition, and support sustainability efforts. Businesses should carefully consider product requirements, budget, materials, design, sustainability, and additional considerations when choosing a custom packaging solution. By creating custom packaging solutions that align with their values, meet their specific requirements, and promote their brand identity effectively, businesses can differentiate themselves in a crowded marketplace and create a memorable customer experience.

If you are interested in custom packaging solutions, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Custom Packaging: Everything You Need to Know and More

Once the design and material selection for a Point of Purchase (POP) display are locked in, the project moves into the critical production phase. This

When it comes to shipping bikes, selecting the right type of corrugated box is essential to ensure product protection, ease of handling, and cost efficiency.

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around