Home » Cost vs. Protection: Balancing Aspects of Protective Packaging

Cost vs. Protection: Balancing Aspects of Protective Packaging

In today’s fast-paced world, protective packaging plays a crucial role in safeguarding products during transportation, handling, and storage. It acts as a shield against various external factors, including impacts, vibrations, moisture, temperature variations, and more. However, businesses often face the challenge of balancing the cost of packaging materials and the level of protection required. This blog explores the delicate balance between cost and protection and provides detailed insights into optimizing packaging choices.

Understanding the Importance of Protective Packaging

Protective packaging serves two primary purposes: preserving product integrity and minimizing damage risks. Whether it’s fragile electronics, delicate glassware, or perishable goods, proper packaging ensures that products reach customers in pristine condition. It helps prevent loss, enhances customer satisfaction, and maintains brand reputation.

Factors Influencing Packaging Choices

Nature of the Product

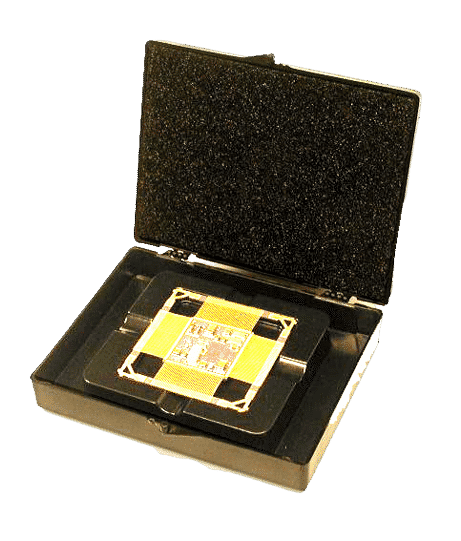

- Fragility: Fragile items, such as glass or electronic components, require extra layers of cushioning to protect against impacts and vibrations.

- Perishability: Perishable goods, like food or pharmaceuticals, may require temperature-controlled packaging to maintain product freshness and quality.

Transportation Method

- Air Transportation: Air freight involves multiple handling points and potential turbulence. Packaging for air transportation should be designed to withstand these challenges, providing adequate protection against impacts and pressure changes.

- Sea Transportation: Shipping by sea introduces the risk of moisture and salt exposure. Packaging materials should be moisture-resistant and provide corrosion protection.

- Land Transportation: Road or rail transportation involves various vibrations and rough handling. Packaging should be robust enough to withstand these conditions.

Storage Conditions

- Duration of Storage: If products are stored for an extended period, protection against environmental factors such as humidity, dust, and temperature fluctuations become crucial. Packaging materials should provide insulation and barrier properties as needed.

- Storage Environment: Warehouses or storage facilities may have specific conditions that impact packaging requirements. For example, if products are stored outdoors, packaging should offer protection against UV radiation and weather elements.

Regulatory Compliance

- Industries such as pharmaceuticals, hazardous goods, or food products have specific packaging regulations to ensure safety and compliance. Packaging materials must meet these requirements, which may impact costs.

Cost Considerations in Protective Packaging

Material Selection

- Traditional Materials: Bubble wrap, foam inserts, corrugated cardboard, and air pillows are widely used and cost-effective options for protection. They provide cushioning, shock absorption, and product support.

- Sustainable Materials: Eco-friendly packaging materials, such as recycled paper, biodegradable plastics, and compostable materials, offer a more environmentally responsible option. While these materials may have a higher upfront cost, they can enhance brand image and customer perception.

Quantity and Volume Discounts

- Businesses that require large volumes of packaging materials can explore bulk purchasing options. Suppliers often offer discounts for bulk orders, reducing the overall packaging costs.

Customization

- Tailoring packaging solutions to the specific needs of the product can optimize costs. Custom-sized boxes, inserts, or dividers can reduce material waste and improve overall protection. Custom packaging also provides a more tailored and professional presentation.

Optimizing Cost-Effective Protection

Packaging Design

- Efficient designs maximize the use of materials, reduce waste, and minimize costs. Packaging engineers can create innovative designs that achieve optimal protection while using fewer materials.

- Utilizing standardized packaging sizes can improve efficiency in terms of storage space, transportation, and handling.

Testing and Prototyping

- Conducting thorough testing and prototyping can help identify the minimum level of protection required. By simulating real-world conditions, businesses can determine the most cost-effective packaging solution that meets the necessary protective standards. Testing may involve drop tests, compression tests, or vibration tests.

Supply Chain Collaboration

- Collaborating with suppliers and logistics partners can provide valuable insights into cost-effective protective packaging solutions. By working together, it’s possible to identify opportunities for efficiency improvements and cost reduction. Partnerships can also facilitate the sharing of best practices and industry knowledge.

Sustainable Packaging Solutions

In recent years, sustainability has become a significant concern for both businesses and consumers. Balancing cost and protection while also addressing environmental considerations is essential. Opting for eco-friendly materials, reducing packaging waste, and adopting recyclable or biodegradable options can align cost savings with environmental responsibility. These measures can enhance brand reputation, attract eco-conscious customers, and contribute to a greener future.

If you are interested in protective packaging or packaging designed to protect your product, then partner with Brown Packaging today. Our experts will help you maintain cost, while optimizing your product’s protection.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » Cost vs. Protection: Balancing Aspects of Protective Packaging

In October 2024, California made a groundbreaking move by banning “sell by” dates on food products. This legislation aims to reduce consumer confusion, minimize food

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,

In the packaging industry, achieving the perfect balance between ensuring product safety and optimizing space is a complex yet vital goal. This blog post explores