Home » Corrugated vs. Plastic Corrugated Packaging

Corrugated vs. Plastic Corrugated Packaging

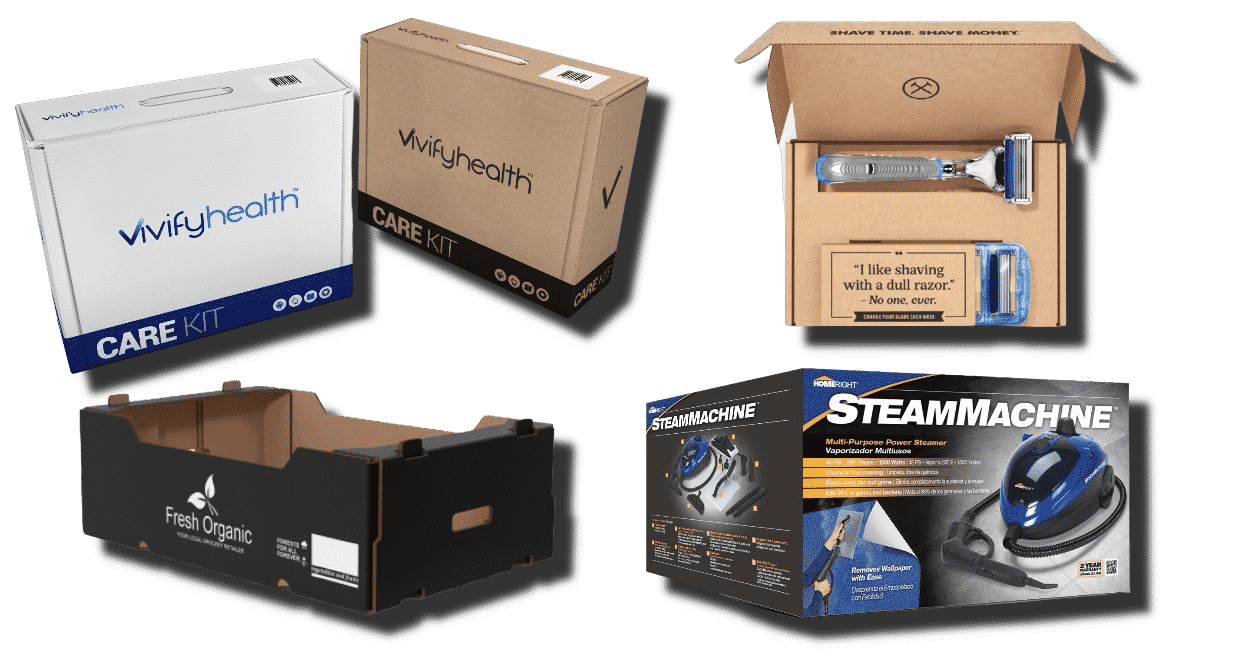

In the dynamic world of packaging, two materials often stand at the forefront: traditional corrugated cardboard and its modern counterpart, plastic corrugated. While both have their unique advantages and applications, understanding the nuances between them is crucial for businesses and consumers alike. This blog post delves deep into comparing these two popular packaging materials.

Corrugated Cardboard: The Classic Choice

History and Composition Corrugated cardboard has been a staple in packaging for over a century. Its structure, featuring a fluted corrugated sheet sandwiched between two flat linerboards, provides a blend of strength and cushioning.

Eco-Friendly and Recyclable A significant advantage of corrugated cardboard is its environmental friendliness. Made from renewable resources (mainly recycled paper and pulp), it is biodegradable and widely recycled.

Cost-Effectiveness For businesses looking to minimize packaging costs, corrugated cardboard is often the go-to choice. Its materials and production process are relatively inexpensive, making it an economical option for bulk packaging.

Limitations However, corrugated cardboard isn’t without its drawbacks. It’s susceptible to moisture and isn’t the most durable option for long-term or heavy-duty packaging.

Plastic Corrugated: The Modern Alternative

Composition and Durability Plastic corrugated sheets, made from polypropylene or polyethylene, are known for their durability. Unlike cardboard, they are resistant to moisture, chemicals, and impacts, making them suitable for more rigorous applications.

Reusability and Longevity One of the most significant advantages of plastic corrugated is its reusability. These materials can withstand repeated use without significant degradation, offering long-term cost savings despite a higher initial cost.

Versatility Plastic corrugated is available in various colors and can be easily customized, offering aesthetic and branding advantages. Its flexibility in design makes it ideal for specialized packaging needs.

Environmental Considerations While plastic corrugated is recyclable, its environmental impact is a point of contention. The recycling process is more complex than that of cardboard, and if not properly recycled, it contributes to plastic pollution.

Choosing the Right Material for Your Packaging Needs

Assessing Product Requirements The choice between corrugated and plastic corrugated depends largely on the product being packaged. For lightweight, short-term, or cost-sensitive applications, corrugated cardboard is often sufficient. However, for heavier, long-term, or moisture-sensitive products, plastic corrugated may be the better option.

Cost vs. Sustainability Budget constraints and environmental considerations play a significant role. Businesses committed to sustainability might prefer corrugated cardboard, while those requiring durability and long-term use might lean towards plastic corrugated.

If you are interested in corrugated or plastic corrugated packaging, then partner with Brown Packaging today to get started.

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers should review in 2026 when sourcing or redesigning subscription packaging. Branding and Unboxing Experience Seasonal or rotating graphics to keep unboxing fresh. Premium finishes such as foil, embossing, or unique die-cuts. Easy-open features like tear strips for convenience. Right-Sizing and Efficiency Reduce DIM charges with packaging tailored to product sizes. Use modular designs to cover multiple SKUs with fewer box sizes. Ensure packaging works with automation to speed fulfillment. Protection and Durability Inserts that prevent product shifting during transit. ISTA-tested designs to withstand vibration and drops. Moisture-resistant coatings for temperature-sensitive items. Sustainability Requirements FSC-certified corrugated or recycled substrates. Recyclable coatings or compostable options. Clear sustainability messaging to support consumer expectations. Cost Control SKU rationalization to limit unnecessary box variations. Material selection that balances protection and price. Supplier contracts that secure pricing for seasonal peaks. Packaging Solutions with Brown Packaging Brown Packaging designs subscription packaging that combines branding, protection, and sustainability. From FSC-certified corrugated to custom inserts, our solutions help buyers create packaging that builds loyalty and controls costs in 2026. Contact us to review your subscription packaging program. References Sustainable Packaging Coalition. (2023). Subscription Packaging and Consumer Insights. Retrieved from https://sustainablepackaging.orgForest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Ecommerce Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated customers. The key is balancing material use, box design, and supply chain efficiency so that savings do not come at the expense of protection. Where Packaging Costs Add Up Oversized boxes: Drive dimensional weight charges. Excess materials: Overuse of void fill and inserts. Complex SKU mix: Redundant sizes increase inventory costs. Inefficient freight: Poor palletization and stacking. Cost-Saving Strategies That Maintain Protection Right-sizing: Match box size to product dimensions to cut DIM charges and material use. Optimize corrugated grades: Switch to single- or double-wall where appropriate without compromising strength. Consolidate SKUs: Streamline packaging options to reduce inventory overhead. Efficient inserts: Replace foam or excess dunnage with engineered corrugated or molded pulp. Supplier contracts: Negotiate based on annual volumes, not just peak season orders. Testing Before Implementing Changes Use ASTM and ISTA protocols to ensure changes won’t increase product damage. Test for compression, vibration, and drop resistance. Run pilot shipments before scaling across the supply chain. Balancing Sustainability and Cost Eco-friendly doesn’t have to mean expensive: Use recyclable coatings to reduce plastic films. Choose corrugated designs that require less material while maintaining stacking strength. Highlight sustainable solutions in marketing to offset cost concerns. Packaging Solutions with Brown Packaging Brown Packaging helps companies lower costs while protecting products across the supply chain. From SKU rationalization to right-sized corrugated solutions, our team ensures packaging savings don’t compromise performance. Contact us to optimize your packaging program. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.Sustainable Packaging Coalition. (2023). Packaging Efficiency and Waste Reduction Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping, and automation create new challenges for packaging buyers. The right materials, testing, and design strategies are critical to protecting products while controlling costs. Why Damage Prevention Matters Financial losses: Damaged products increase replacement and freight costs. Customer impact: Poor delivery experience reduces loyalty and repeat sales. Sustainability: Returns and waste drive higher carbon footprints. Compliance: Retailers often impose penalties for damaged shipments. Common Causes of Product Damage Compression: Pallet stacking weakens boxes in transit. Vibration and shock: Long-haul shipping increases risk. Moisture exposure: Humidity and rain compromise corrugated performance. Poor right-sizing: Oversized boxes allow product movement inside. Strategies to Reduce Damage in 2026 Right-size packaging: Minimize empty space and movement. Material optimization: Choose the correct corrugated grade for load demands. Protective inserts: Molded pulp or engineered corrugated reduce shock. Moisture-resistant coatings: Defend against water and humidity. Automation-friendly design: Prevent jams that damage products on high-speed lines. Testing Protocols for Damage Prevention ISTA testing: Simulates vibration, drops, and compression. ASTM standards: Validate packaging strength and durability. Pilot shipments: Real-world trials confirm lab results. Packaging Solutions with Brown Packaging Brown Packaging designs solutions that minimize damage across today’s complex supply chains. From right-sized corrugated to ISTA-tested inserts, we help buyers protect products while reducing costs. Contact us to strengthen your packaging program. References ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Corrugated vs. Plastic Corrugated Packaging

Corrugated boxes are highly effective for a wide range of packaging needs, providing superior protection, durability, and versatility. Their unique construction allows them to withstand various stresses during shipping and storage, making them a preferred choice for businesses and consumers alike. The Structure of Corrugated Boxes The effectiveness of corrugated boxes starts with their structure. Made from corrugated fiberboard, which includes a fluted corrugated sheet sandwiched between two flat linerboards, these boxes offer a robust design capable of absorbing shock and preventing damage to the contents. This structure not only imparts strength but also provides insulation that can protect against temperature variations. Versatility and Customization Corrugated boxes are celebrated for their versatility. They can be custom-manufactured to fit any size, shape, or weight requirement, ensuring that products, regardless of their dimensions, can be securely packaged with minimal movement inside the box. This customizability extends to the printing and branding of the boxes, making them an effective marketing tool in addition to their primary function of protection. Sustainability One of the most compelling advantages of corrugated boxes is their sustainability. Made from renewable resources, primarily recycled paper and cardboard, these boxes can be recycled again after their lifecycle, reducing waste and the demand for raw materials. The recycling process for corrugated cardboard is efficient and widespread, contributing to its status as one of the most recycled materials in the world. Durability and Protection The durability of corrugated boxes is a key factor in their effectiveness. They are designed to resist tears, splits, and bursts, which can occur during handling and transit. The fluting within the cardboard also provides a cushion for the items inside, protecting against impacts. Furthermore, corrugated boxes can be treated with coatings or laminates to make them resistant to moisture, oil, and other environmental factors, thereby enhancing the protection they offer. Cost-Effectiveness Corrugated boxes are cost-effective, offering a high level of protection relative to their cost. They are lightweight, which reduces shipping costs, and their material and construction costs are lower compared to alternative packaging options. This cost-effectiveness makes corrugated boxes an attractive option for a wide range of industries, from e-commerce to retail and beyond. Challenges and Considerations While corrugated boxes are effective, there are considerations to keep in mind. The integrity of the box can be compromised by overloading, improper handling, or exposure to damp conditions. However, these challenges can be mitigated through proper design, handling, and storage practices. Conclusion In conclusion, corrugated boxes offer an effective solution for packaging needs across various industries. Their strength, flexibility, sustainability, and cost-effectiveness make them a superior choice for protecting goods during transit and storage. By leveraging the inherent benefits of corrugated boxes and adhering to best practices for their use, businesses can ensure the safety of their products while also contributing to environmental sustainability. If you are interested in corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Corrugated Boxes are exposed to many different circumstances during packing, shipping and storage. Ensuring that your corrugated packaging is protecting your product fully is important. The two-test used to evaluate the strength of your packaging are Mullen Burst Test and Edge Crush Test. They both serve a similar purpose of testing the strength of the box, and they test it in different ways. It is important to understand the difference between the two tests, in order to ensure you pick the right strength quality test for your packaging needs. Mullen Burst: The Mullen Burst Test was the first standard box strength test to be used. It uses a pressurized diaphragm to measure how much pressure the side of a corrugated box can endure before it will burst. It is measured in pounds per square inch. This test is best for measuring the forces a box may be subject to during rough handling, as well as the total weight amount the box can hold. It doesn’t measure the amount of weight that can be stacked on top of a box that is when the Edge Crush Test becomes more effective. Edge Crush The Edge Crush Test (ECT) measures the vertical compression along the edge of a package and focuses on the compression and stacking strength of a corrugated box. It is measured by the force in pounds per lineal inch of load bearing edge that a box can take before failure. This test is often used when one is concerned about the max weight a box can handle during pallet shipments and warehouse stacking. More so this test measures how much weight a corrugated box can handle before it would crush. Which test should you use? Edge Crush test is best used when the items you are packaging will not move during shipment, won’t exert lateral force to the sides of the boxes, and won’t go through a variety of different shipment handlers. If you are stacking or palletizing your boxes, ECT can provide a better measure of how the box will hold up during that stacking process. In order to best protect your product from being crushed during shipment, use Edge Crush Test. Mullen Burst test is best if the items in the box will move during shipment, there will be pressure to the sides of the boxes, and the box will go through many different handlers during shipping. If you’re concerned about a package being punctured during shipment use Mullen Burst Test. BMC The Box Manufacturer Certification Stamp (BMC) is added to all corrugated boxes in order to show the boxes strength. Every BMC contains either the Mullen Burst Test Rating or the Edge Crush Test Rating information. This stamp shows that the box is compliant with the regulations set by the National Motor Freight Traffic Association (NMFTA). Although this is not legally required most carriers require it. What is located on a BMC? Box manufacturers name and location Mullen Burst Test Rating or Edge Crush Test Rating Max sum of outside dimensions Max allowed gross weight Board construction Both Mullen Burst Test and Edge Crush Test are useful in their own ways. Although they both serve a similar purpose of testing the strength of the box, these test are not equivalent as they measure completely different things. It is important to understand the difference between the two tests, in order to ensure you pick the right strength quality test for your packaging needs. If you need assistance understanding the difference between these two test and need help determining which one is best for your business packaging needs, then contact Brown Packaging and one of our packaging experts can assist you. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Facebook Twitter LinkedIn Pinterest Relevant Posts

As the packaging industry evolves, corrugated boxes continue to play a pivotal role in shipping, storage, and retail displays. In 2025, businesses will look for more innovative, eco-friendly solutions to meet the increasing demand for sustainability, efficiency, and enhanced user experiences. Below are the top trends expected to shape the future of corrugated boxes: Sustainable Materials and Recycling Lightweight Corrugated Designs Enhanced E-commerce Packaging Custom Branding and Personalization Smart and Connected Packaging Reusable Corrugated Solutions Minimalist Packaging Design Strengthened Protection Features Digital Printing on Corrugated Boxes Cost-Effective Packaging Solutions Sustainable Materials and Recycling Sustainability will be a core focus in 2025, and corrugated boxes will increasingly be made from recycled content and renewable resources. Businesses will prioritize using 100% recyclable and biodegradable materials, reducing the reliance on virgin fiber. In addition, closed-loop recycling systems will allow for more efficient material reuse. Lightweight Corrugated Designs Lightweight corrugated packaging will grow in popularity due to its ability to reduce transportation emissions and shipping costs. In 2025, more brands will adopt thinner yet stronger corrugated materials that maintain durability while cutting down on overall material usage, minimizing environmental impact. Enhanced E-commerce Packaging As e-commerce continues to expand, corrugated boxes specifically designed for online retail will be in high demand. These boxes will need to balance durability and protection with sustainability, using materials that are both sturdy and lightweight. Additionally, frustration-free packaging designs, which are easy to open and reduce excess waste, will become a standard. Custom Branding and Personalization Custom-printed corrugated boxes will remain a key trend in 2025 as brands seek to enhance the unboxing experience. Personalization and custom branding on corrugated boxes not only improve product presentation but also help businesses build stronger connections with consumers. Digital printing advancements will allow for more affordable and detailed customization options, even for small runs. Smart and Connected Packaging The integration of smart technology with corrugated boxes will increase, incorporating elements like QR codes, RFID tags, and NFC chips. These innovations provide real-time tracking information, ensure product authenticity, and allow consumers to interact with brands in new ways. Smart packaging is also expected to play a larger role in enhancing the supply chain with better inventory management and tracking. Reusable Corrugated Solutions In response to the push for more sustainable packaging, reusable corrugated boxes will see growing adoption. Brands are increasingly looking at designing corrugated packaging that can be used multiple times before disposal or recycling. This trend not only reduces waste but also offers cost savings for businesses focused on long-term sustainability. Minimalist Packaging Design Minimalism continues to dominate the packaging industry, with more brands opting for simple, clean designs that reduce the amount of material used. Minimalist packaging resonates with consumers who prefer environmentally conscious brands and products. In corrugated packaging, this trend translates into smaller, more efficient boxes that still offer high-level protection. Strengthened Protection Features With more sensitive products being shipped globally, the need for enhanced protection in corrugated boxes will rise. Advances in box construction and the integration of protective materials like inserts or reinforced corners will ensure better protection while minimizing material usage. Expect packaging that not only looks good but also performs better in harsh shipping conditions. Digital Printing on Corrugated Boxes Digital printing technology is expected to make huge strides by 2025, offering companies faster, more affordable customization on corrugated boxes. With fewer limitations on color and design complexity, businesses will be able to create vibrant, branded packaging in smaller runs, allowing for cost-efficient personalization without the need for large-scale production. Cost-Effective Packaging Solutions As businesses continue to navigate cost pressures, corrugated boxes will remain a go-to for affordable packaging. Innovations in materials, design, and production methods will help keep costs low while meeting the growing demands for sustainability and durability. Expect to see more flexible, cost-efficient options that still deliver on protection and presentation. In 2025, corrugated boxes will remain a crucial part of the packaging industry, balancing innovation with sustainability. Companies that adopt these trends will be well-positioned to meet evolving consumer and regulatory expectations while staying competitive in a dynamic marketplace. If your interested in corrugated boxes for 2025, whether they are custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts