Home » Corrugated RSC Boxes vs. Full-Overlap (FOL) Boxes

Corrugated RSC Boxes vs. Full-Overlap (FOL) Boxes

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box and the Full-Overlap (FOL) box. Each style caters to specific packaging needs, making them suitable for various applications. In this comparative analysis, we will explore the characteristics, use cases, advantages, and considerations of Corrugated RSC Boxes and Full-Overlap (FOL) Boxes to help you determine which is the right choice for your packaging requirements.

What is a (RSC) Box?

Regular Slotted Container (RSC) boxes are known for their simplicity and efficiency in design and production. They feature four flaps—two on the top and two on the bottom—that meet in the center when closed. RSC boxes are cost-effective and widely used across industries.

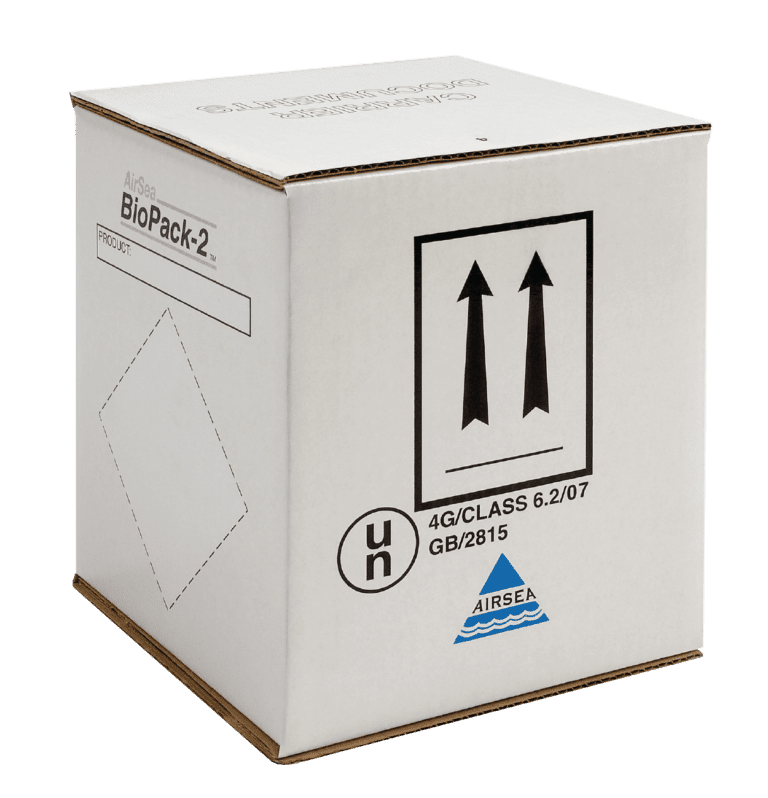

What is a Full-Overlap (FOL) Box?

Full-Overlap (FOL) boxes, in contrast, are designed with flaps that fully overlap when closed, providing added protection and structural integrity. These boxes excel in safeguarding products during transit, making them ideal for items that require extra strength and stability.

A Comparative Analysis

Design and Closure:

Corrugated (RSC) Box:

- RSC boxes offer a straightforward design, making them easy to assemble and close with tape or adhesive.

- Closure involves folding the flaps on the top and bottom, taping or gluing to a secure seal.

Full-Overlap (FOL) Box:

- FOL boxes feature overlapping flaps, enhancing structural integrity and security.

- The flaps provide additional protection and resistance to crushing, making FOL boxes ideal for fragile or heavy items.

Protection and Strength:

Corrugated (RSC) Box:

- RSC boxes offer standard protection and are suitable for a wide range of products.

- While they provide adequate strength, they may not be the best choice for heavy or delicate items.

Full-Overlap (FOL) Box:

- FOL boxes excel in providing enhanced protection and structural integrity.

- They are ideal for shipping heavy, fragile or valuable items, including electronics, glassware, and machinery.

Versatility:

Corrugated (RSC) Box:

- RSC boxes are versatile and can be used for various products and industries.

- They are cost-effective and readily available in standard sizes.

Full-Overlap (FOL) Box:

- FOL boxes are versatile as well but are often chosen for specific applications requiring superior protection.

- They may be slightly more expensive than RSC boxes due to their specialized design.

Customization:

Corrugated (RSC) Box:

- RSC boxes can be customized with printed graphics and branding, enhancing their visual appeal.

Full-Overlap (FOL) Box:

- FOL boxes can also be customized with branding and graphics and are often used for premium or high-end products.

Cost-Efficiency:

Corrugated (RSC) Box:

- RSC boxes are generally more cost-effective due to their simpler design and ease of production.

Full-Overlap (FOL) Box:

- FOL boxes may come at a slightly higher cost, primarily due to their enhanced protective features.

Choosing the Right Box for Your Needs

The choice between Corrugated RSC Boxes and Full-Overlap (FOL) Boxes hinges on your specific packaging requirements. Here are some considerations:

- If you need a cost-effective and versatile solution for standard products, Corrugated RSC Boxes are a practical choice.

- If you’re shipping fragile or valuable items, heavy machinery, or electronics, Full-Overlap (FOL) Boxes offer superior protection and structural integrity.

- Customization and branding are possible with both box styles, allowing you to create a unique packaging experience for your customers.

If you are interested corrugated boxes like RSC, FOL and other styles, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Corrugated RSC Boxes vs. Full-Overlap (FOL) Boxes

Packaging plays a crucial role in protecting products during transportation and handling. However, not all packaging materials, such as corrugated are created equal, and choosing

Understanding One-Piece FOL and Three-Piece Bike Shipping Boxes Choosing the right box style is essential when shipping bicycles—especially for brands, manufacturers, and distributors focused on

In the world of packaging and delivery, corrugated boxes have long been the workhorse of choice. Known for their durability, flexibility, and affordability, these boxes