Home » Corrugated Print Quality: ECT vs. Bursting (Mullen) Test Board

Corrugated Print Quality: ECT vs. Bursting (Mullen) Test Board

When choosing corrugated board for packaging, print quality is often a critical consideration. Two common board types—ECT (Edge Crush Test) board and Bursting Test board, also called Mullen Test board—have distinct surface characteristics that impact the final print results, especially when using flexographic (flexo) printing. While both boards serve their structural purposes, their composition affects ink absorption, print clarity, and overall aesthetics.

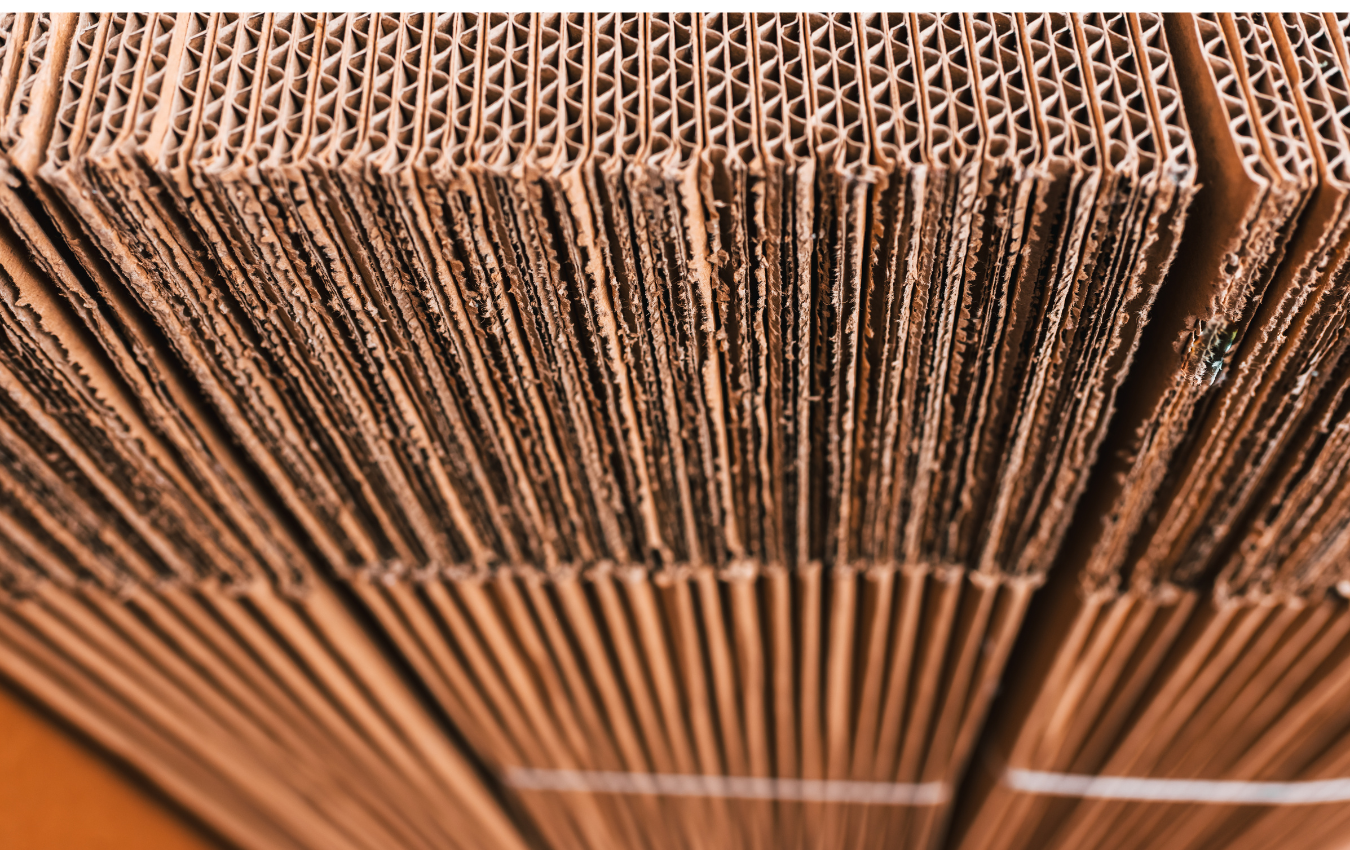

Why Does ECT Board Struggle With Print Quality?

ECT board is designed primarily for stacking strength rather than printing quality. It is rougher and more porous compared to Test board, which results in the following print challenges:

- Ink Absorption Issues: The more porous nature of ECT board allows ink to spread unevenly, leading to a muddy, less defined print.

- Uneven Surface Texture: Rough fibers on ECT board prevent fine details and crisp lines from transferring properly, resulting in a blurry or inconsistent appearance.

- Reduced Ink Holdout: Because the ink penetrates deeper into the material, colors may appear duller and less vibrant compared to smoother boards.

Can You Improve Print Quality on ECT Board?

For brands requiring higher-quality graphics on an ECT board, one option is to order virgin kraft liners instead of standard recycled liners. Virgin kraft liners:

- Have a smoother, more uniform surface, allowing for better ink adhesion and sharper details.

- Reduce ink absorption, leading to brighter, more vibrant prints.

- Are stronger and cleaner-looking, improving the overall aesthetic of the packaging.

When to Use Bursting Test Board Instead

Test board, made from a mix of virgin and recycled fibers, tends to be smoother than ECT board, allowing for better ink retention and detail clarity. If print quality is a priority, a Test board with a higher-quality white or coated liner can significantly improve the final result.

Final Considerations

If your primary concern is cost and stacking strength, ECT board is a solid choice, but expect compromises in print quality when using flexo. For higher-quality branding and graphics, consider upgrading to a Test board or requesting virgin kraft liners to enhance your print results.

Need help selecting the right corrugated board for your packaging? Contact Brown Packaging today to find the best option for your needs!

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers predict failures, validate material changes,

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

Home » Corrugated Print Quality: ECT vs. Bursting (Mullen) Test Board