Home » Comparing Plastic Bins vs. Corrugated Bin Boxes

Comparing Plastic Bins vs. Corrugated Bin Boxes

Storage is an essential aspect of our daily lives, be it for personal use or in the professional sector. The need for effective and efficient storage has led to the development of various storage solutions. In this blog, we will delve deep into a comparison between corrugated bin boxes and one of the most popular storage alternatives – plastic bins. Our primary focus will be on durability and lifespan.

What are Corrugated Bin Boxes?

Corrugated bin boxes are made from corrugated cardboard. They are commonly used in warehouses, offices, and retail settings for sorting and storing small items. The design is simple: a rectangular open-top box that can be easily labeled and stacked. The primary material – corrugated cardboard – comprises fluted or arched layers sandwiched between two linerboards, which provides strength and rigidity.

What are Plastic Bins?

Plastic bins are storage containers made of different types of plastic materials. They come in a myriad of sizes, colors, and designs, ranging from small organizational bins to large tote containers. Their use spans from households to industrial settings, with special designs like stackable or lidded options available based on needs.

Durability: Plastic Bins vs. Corrugated Bin Boxes

Plastic Bins

- Strength: Plastic bins are generally stronger and more resilient than corrugated bin boxes. They can handle rougher treatment, such as being tossed around or holding heavier items.

- Weather Resistance: Plastic bins offer better protection against moisture, humidity, and other environmental factors. They can be used in settings where corrugated bin boxes might deteriorate quickly, such as damp basements or outdoor storage.

- Wear and Tear: Plastic is resistant to tearing, denting, and breaking, making plastic bins more durable in environments with frequent handling or movement.

Corrugated Bin Boxes

- Strength: While corrugated bin boxes provide reasonable strength due to their fluted structure, they are not as robust as plastic bins. They are best suited for lighter items and gentler handling.

- Weather Resistance: Corrugated boxes are susceptible to moisture and can degrade if exposed to water or high humidity for extended periods.

- Wear and Tear: Over time, corrugated boxes may start to wear out, especially at the edges or corners. They are also more prone to tearing if mishandled.

Lifespan: Plastic Bins vs. Corrugated Bin Boxes

Plastic Bins: The lifespan of plastic bins can range from several years to decades, depending on the quality of the plastic and the conditions in which they’re used. High-quality, heavy-duty plastic bins can last a very long time, especially if they’re not exposed to direct sunlight (which can degrade certain plastics) or extreme temperatures.

Corrugated Bin Boxes: The lifespan of a corrugated bin box is generally shorter than that of a plastic bin. Under optimal conditions, they can last several years. However, frequent use, exposure to moisture, or heavy contents can significantly shorten their life. They are often considered a more temporary or recyclable solution compared to plastic bins.

Conclusion

Both plastic bins and corrugated bin boxes offer unique advantages. The choice between the two will largely depend on your specific needs. If you require a more durable, long-lasting, and weather-resistant solution, plastic bins are the way to go. On the other hand, if you are looking for a more eco-friendly, recyclable, or temporary storage solution, corrugated bin boxes might be the better choice. Regardless of the option you select, always consider the storage environment, the items you’re storing, and the frequency of use to make the most informed decision.

If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Comparing Plastic Bins vs. Corrugated Bin Boxes

RETT boxes are a popular type of corrugated mailer used by the retail and ecommerce industry to ship and display products. These boxes are designed

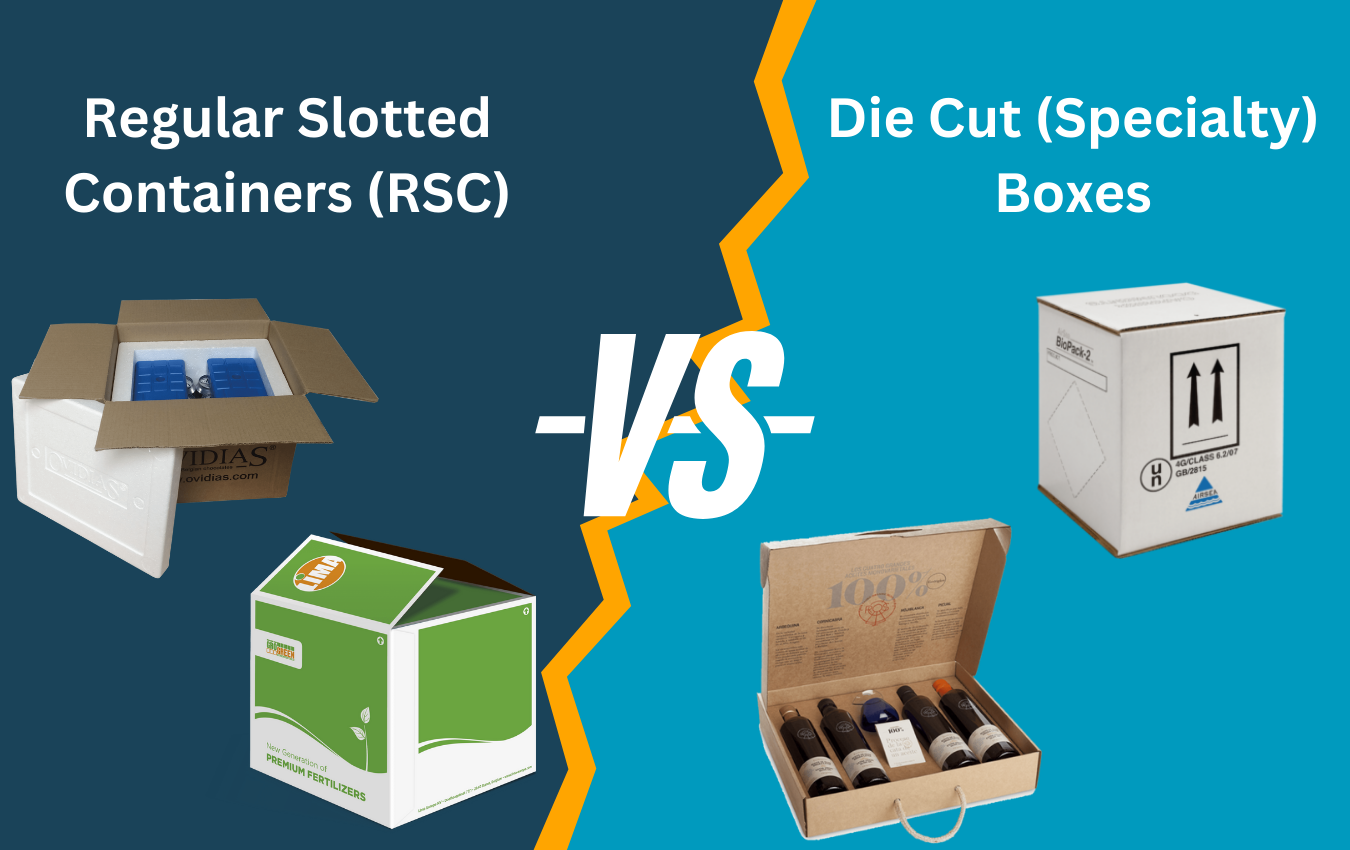

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and