Home » Chipboard Packaging Explained: Products, Benefits & Applications

Chipboard Packaging Explained: Products, Benefits & Applications

What is Chipboard?

Chipboard is made from small wood particles mixed with resin, binders and other additives, which is then pressed together under high temperature with high amounts of pressure. It is thicker than normal paper, but doesn’t have flutes like corrugated boxes. Chipboard normally comes in a single layer material, but it can come in a variety of thicknesses dependent on your packaging needs. This type of packaging is not meant for shipping purposes, it is best used for small consumer goods. For the purposes of this blog SBS, CCNB, CNK, SUS, and other similar products are included in this chipboard category.

Advantages:

- Cost Efficient: Lower production and shipping cost.

- Better for Storage: Takes up less space when being stored compared to other packaging products.

- Printing: Ideal for design and customization and can be directly printed on.

- Flexible: Easier to cut, fold and shape due to thinner material.

- Protection: The density of the material gives strength and protection against possible damage.

- Environmental Factors: It is made from recycled material. The energy used to create this product is far less than other packaging options.

Disadvantage:

- Chipboard cannot hold heavy or fragile Items and does not offer as much protection compared to other materials like corrugated.

What are Common Chipboard Applications?

Chipboard is best suited for retail and lightweight displays because this material can be cut and folded into different sizes and thicknesses. Since it is easily customized and printed directly on, it allows for pictures and high-quality designs to be printed directly on the chipboard surface, as opposed to needing secondary labels. It is best used for lightweight and less valuable products due to it not being as strong as corrugated material. Most packaging seen in retail is chipboard material. Examples of this include packaging food, beauty products, pharmaceuticals and other retail items.

What are the Chipboard Packaging Products?

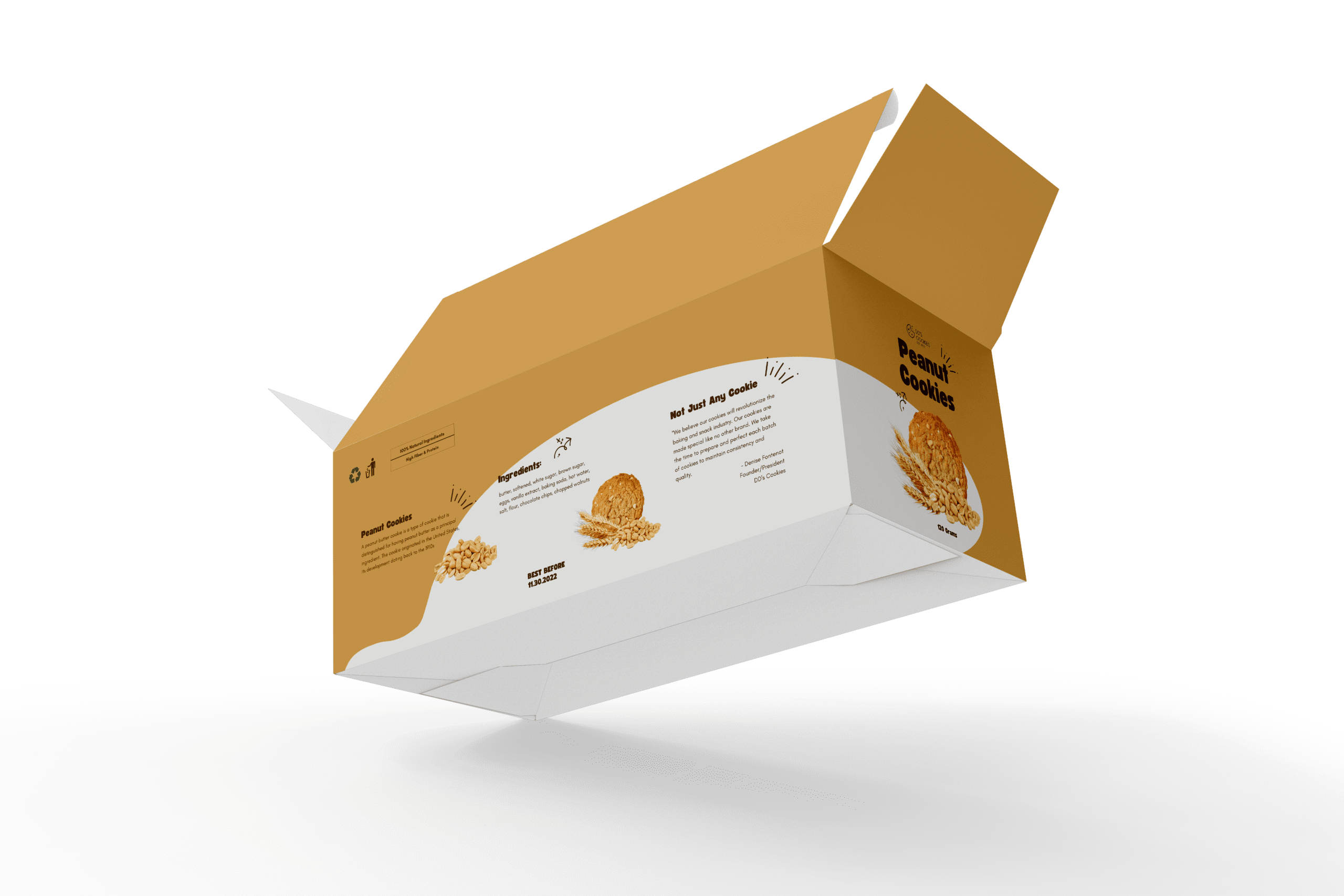

- Folding cartons: Thin flexible paperboard or chipboard cartons used in packaging lightweight products. There are several different folding carton styles some being; Straight Tuck End, Reverse Tuck End, Auto Bottom, Full Seal, Shelf Displays and many other styles.

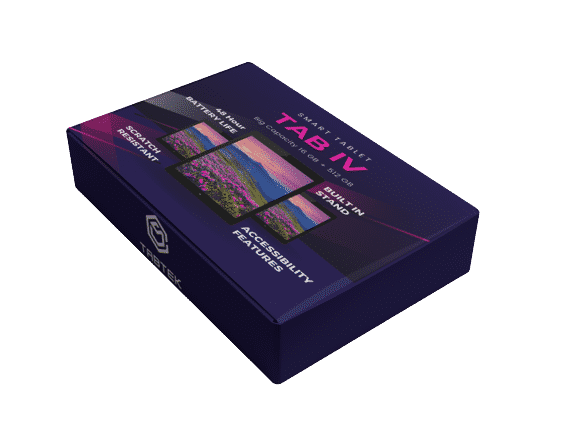

- Setup Boxes: Premium two-piece boxes used to protect luxury items.

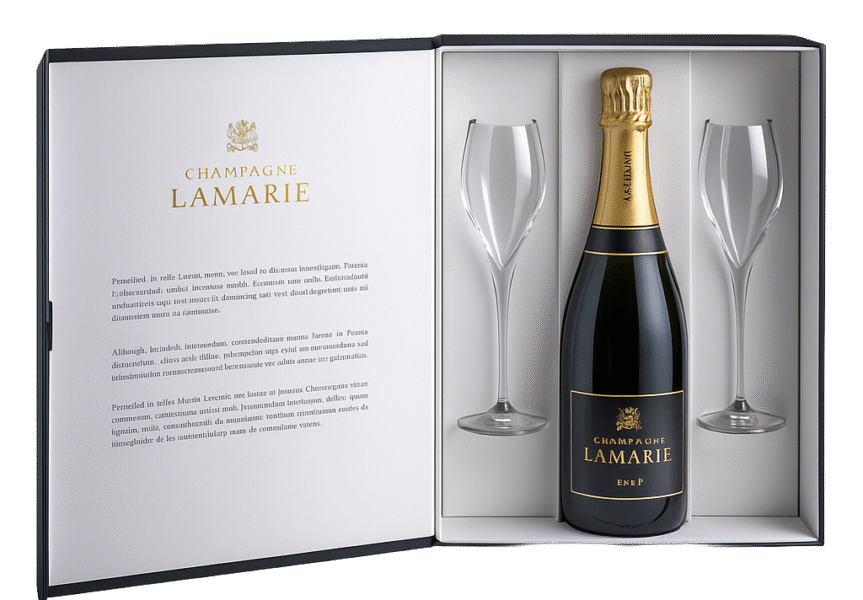

- Inserts: Protect items and prevent them shifting from fulfillment to completion.

- Pads: Used to provide products with extra protection and separate layers.

Straight Tuck End (STE) Folding Carton with hanging tab

Setup Box (Rigid Box)

Inserts

Pads

Is Chipboard Right for your Packaging needs?

Deciding which packaging material will work best for your business needs is an important decision. You must take many factors into consideration when weighing your options. If you are looking for a light weight, cost efficient, highly customizable, and ecofriendly packaging option, then chipboard might be the best option for your packaging needs. If you are needing help deciding if chipboard is the right packaging material for you, contact Brown Packaging today and one of our packaging specialists will assist you.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Chipboard Packaging Explained: Products, Benefits & Applications

In the world of retail, theft and shoplifting pose significant challenges, costing businesses billions of dollars each year. While it may not be possible to

In the realm of marketing, storytelling has evolved into a potent tool for brands to forge meaningful connections with consumers. Beyond the mere sale of

Why Co-Packaging Becomes Critical During the Holidays As the holiday season approaches, packaging teams are under pressure to deliver high volumes of promotional sets, combo