Home » Cherry Locks in Roll End Tuck Top Boxes Explained

Cherry Locks in Roll End Tuck Top Boxes Explained

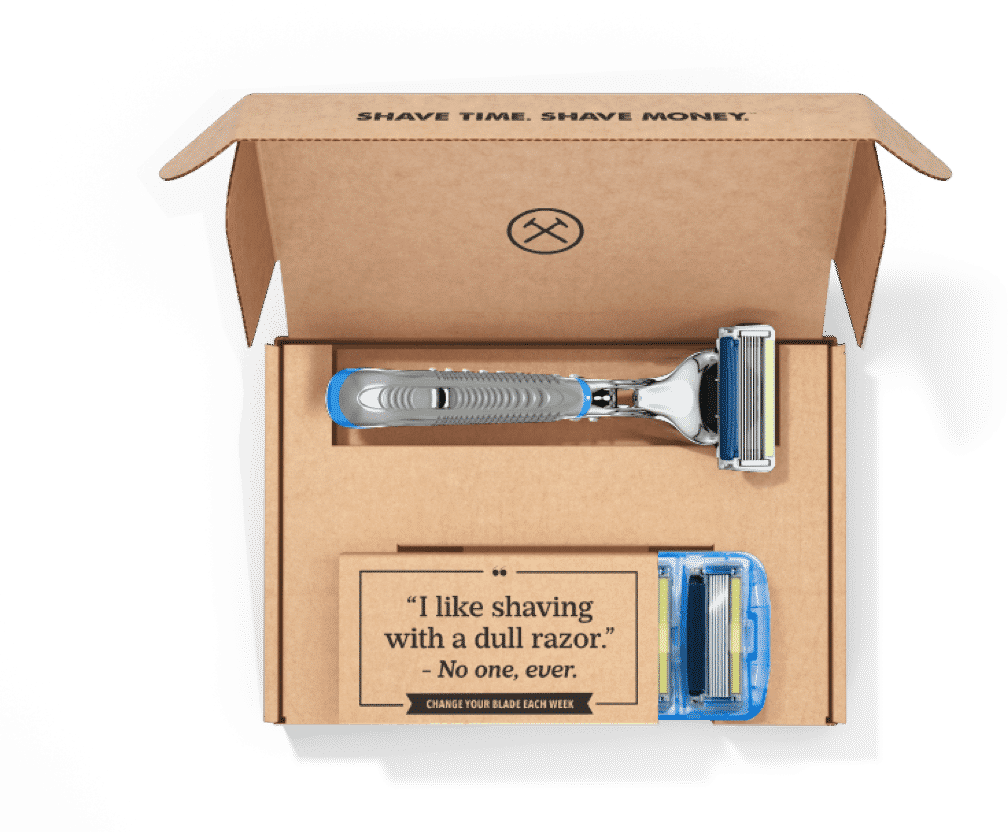

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to access. One such advancement in packaging technology is the incorporation of cherry locks in roll end tuck top (RETT) boxes. In this blog, we will delve into the intricacies of cherry locks, exploring their design, features, benefits, and the scenarios where they prove to be an invaluable addition to RETT boxes.

Understanding Cherry Locks

Cherry locks, also known as snap locks or friction locks, are a locking mechanism employed in packaging to secure the top flaps of boxes without the need for additional adhesives or tape. These locks are specifically designed to offer a secure closure while allowing for effortless and repeated opening, making them ideal for applications where ease of access is crucial. Here’s a closer look at their design and features:

Benefits of Cherry Locks

Cherry locks offer several advantages, making them a valuable addition to RETT boxes:

- Enhanced Security: Cherry locks provide a secure closure that prevents accidental opening during transit while deterring tampering or unauthorized access.

- Easy Access: The user-friendly design of cherry locks allows for quick and effortless opening, making them ideal for products that need to be accessed frequently, such as retail items or subscription boxes.

- Sustainability: Cherry locks contribute to sustainability efforts as they reduce the reliance on single-use adhesives and tapes, promoting eco-friendly packaging practices. These boxes can also be reused and repurposed.

- Cost Savings: While cherry locks may initially seem like a slightly higher investment, their reusability ultimately leads to cost savings by eliminating the need for additional sealing materials.

Cherry Locks in Roll End Tuck Top Boxes

Roll end tuck top boxes, with their inherent durability and versatility, are a perfect pairing for cherry locks. These boxes are constructed to provide a secure enclosure while allowing for easy customization and branding. When cherry locks are integrated into RETT boxes, they bring an added layer of security and convenience to the packaging solution.

Scenarios for Using Cherry Locks in RETT Boxes

Cherry locks are a versatile locking mechanism that can be employed in various industries and applications:

- Retail Packaging: RETT boxes with cherry locks are an excellent choice for retail packaging, ensuring that products remain secure on the shelves while allowing customers to open and inspect them easily.

- E-commerce: For e-commerce businesses, cherry locks enhance the security of shipped items while offering recipients a hassle-free unboxing experience.

- Subscription Boxes: Subscription box services benefit from cherry locks as they combine security with the convenience of repeated opening for subscribers.

- Electronics and Gadgets: Sensitive electronics and gadgets can be securely packaged with cherry locks, ensuring the contents are protected during shipping and readily accessible to users.

Conclusion

Cherry locks in roll end tuck top boxes represent a significant innovation in packaging design, offering the perfect balance between security and ease of access. Understanding the design, features, benefits, and potential applications of cherry locks can help businesses make informed choices when selecting packaging solutions. Whether you are in retail, e-commerce, or any other industry, the integration of cherry locks into RETT boxes can enhance your packaging strategy, providing a secure and user-friendly experience for both businesses and customers alike.

If you are interested in roll end tuck top boxes with cherry locks, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Cherry Locks in Roll End Tuck Top Boxes Explained