Home » Case Study: NOCCO – Premium Rigid Box

Case Study: NOCCO – Premium Rigid Box

- Client Overview:

- Company Name: NOCCO

- Industry: Snack, Dietary & Nutrition

- Company Size: Medium

When NOCCO needed a high-end packaging solution for their influencer and investor campaign, they faced a major challenge—tight deadlines, no initial design, and the need to eliminate foam while still protecting their product. Brown Packaging stepped in, designing and delivering a custom premium rigid box with a sleek finish, innovative structural design, and secure product placement—all within just three weeks. Here’s how we made it happen.

The Challenge/Problem

NOCCO needed a premium packaging solution for a marketing campaign targeting social media influencers, investors, and high-value clients. However, several challenges had to be addressed:

- Tight Lead Time – The packaging had to be designed, tested, and produced within just three weeks.

- Redesign Request – The client previously had these boxes made in Europe but now needed a modified version that could hold 6 cans instead of 2—without the original basketball-themed design.

- Foam-Free Protection – The previous packaging relied on foam to secure the cans, but the client wanted a design that eliminated foam while still preventing damage.

Impact on Their Operations

Without an elevated packaging solution, the client risked missing a valuable marketing opportunity. Their standard packaging lacked the sophistication needed for this campaign, and achieving a high-end look within a short timeline was a challenge.

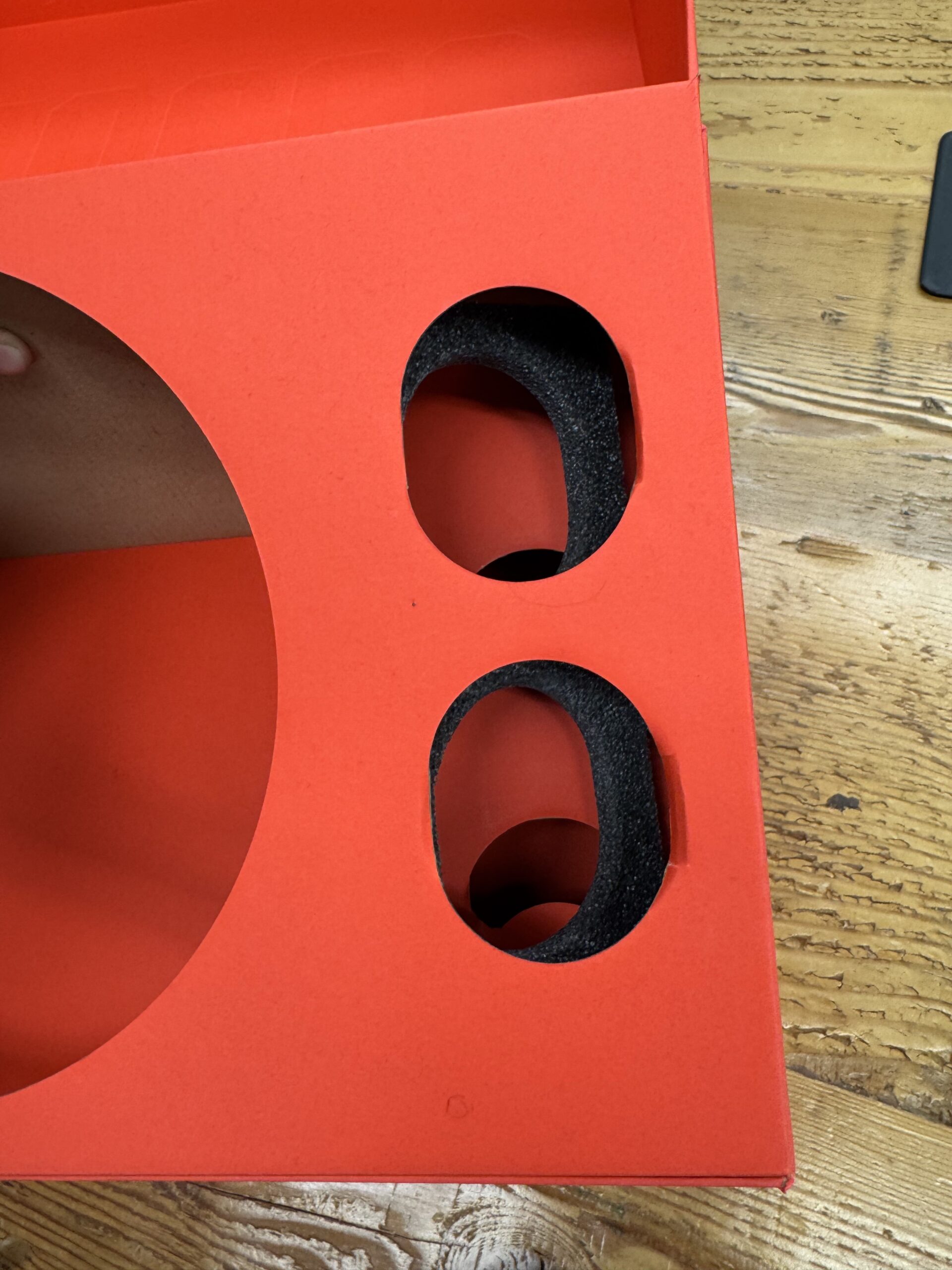

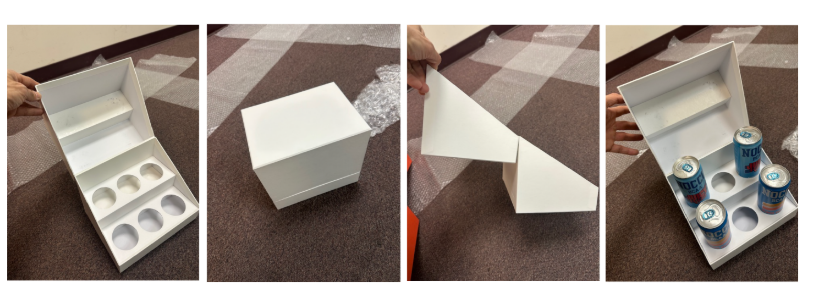

*Images above show our clients original packaging from Europe with the foam*

Solution: Brown Packaging’s Approach

To meet NOCCO’s needs, Brown Packaging developed a premium custom box that improved presentation and product protection while eliminating foam inserts. The solution included:

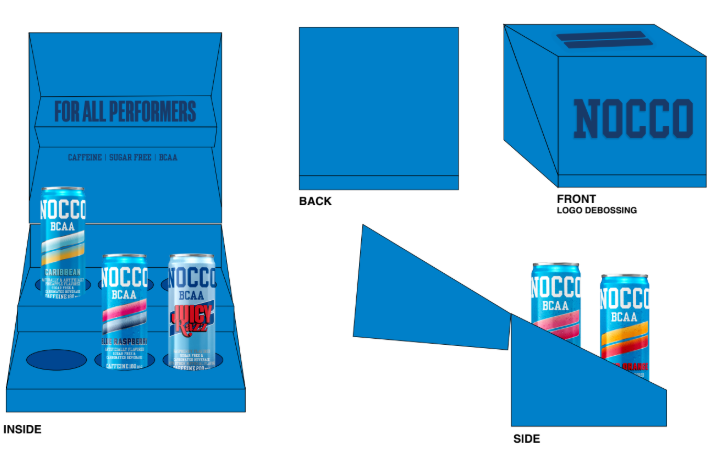

✅ Custom Structural Design – Created a two-layer shelf system that secured the cans in place while providing a tiered display.

✅ Foam-Free Protection – Engineered an insert that held the cans securely, preventing movement and damage without using foam.

✅ 3D Renderings & Prototypes – Provided visual concepts, plain structural samples for testing, and preliminary printed samples for approval.

✅ Premium Materials & Finishes – Designed a high-end soft-touch box with Spot UV on a premium material beyond standard corrugated.

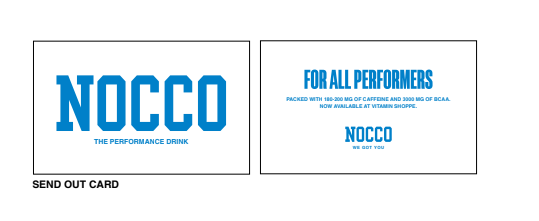

✅ Custom Printed Inserts – Developed a printed insert card to enhance branding and the unboxing experience.

Collaborative Process

- The customer sent reference samples and requested a design that held 6 cans instead of 2.

- Brown Packaging designed a first concept with 3D renderings, which the client approved.

- A structural prototype was produced and refined to eliminate foam while ensuring product protection.

- Artwork die lines were provided, and the client applied their graphics.

- Printed samples were created to verify accuracy before final production.

- All approvals were secured, and the final production run was completed within the three-week deadline.

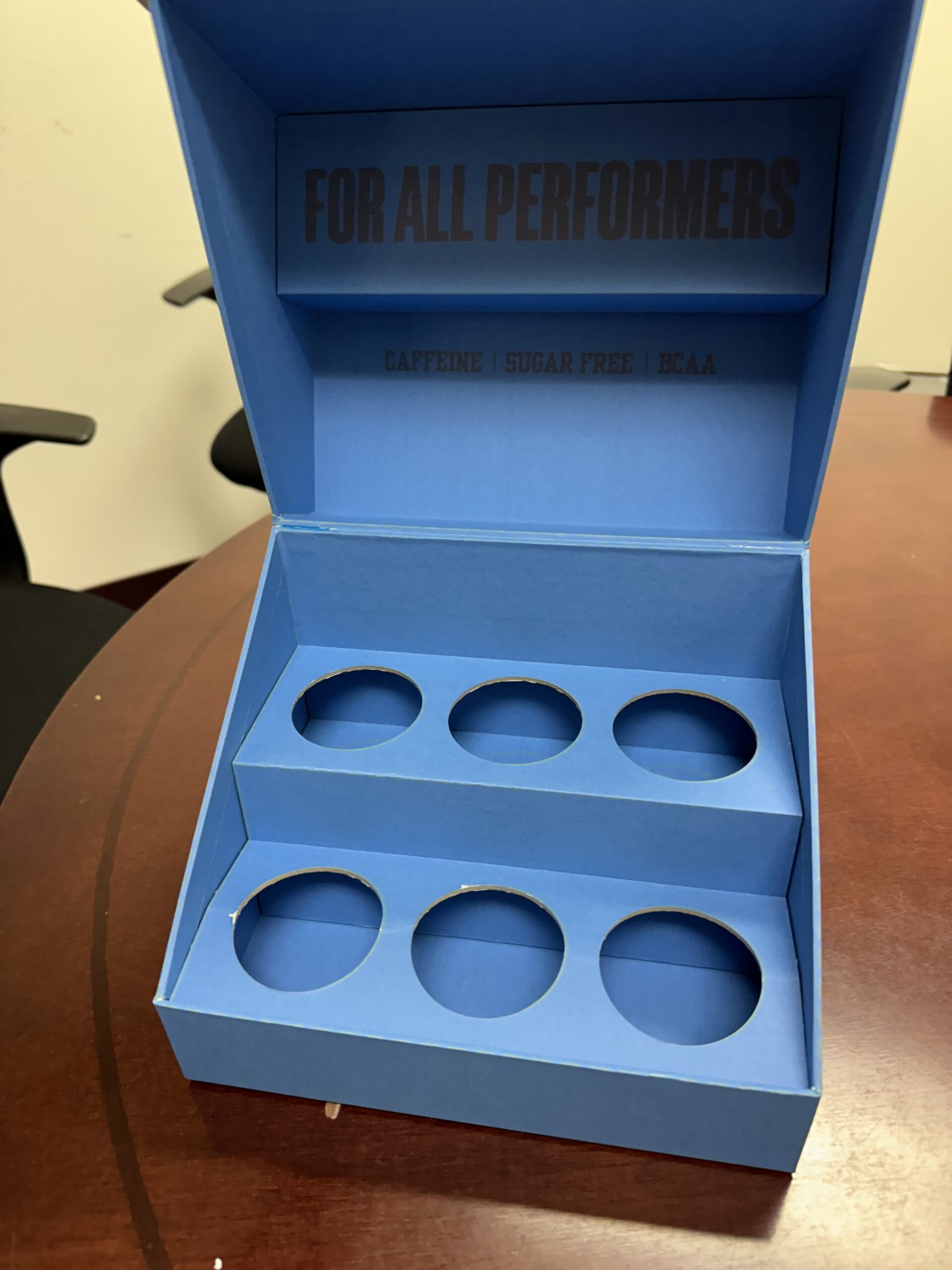

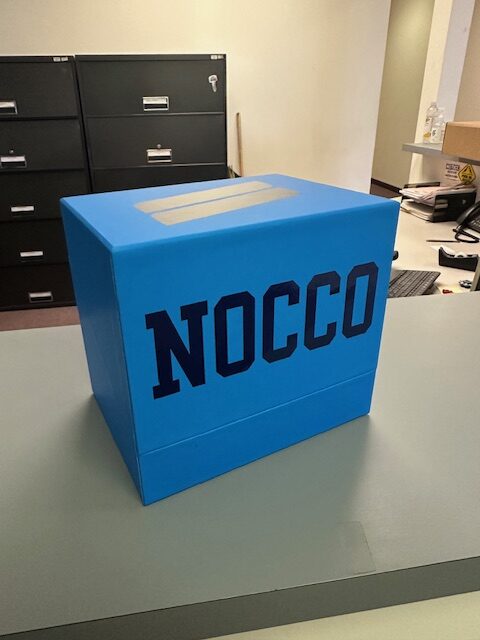

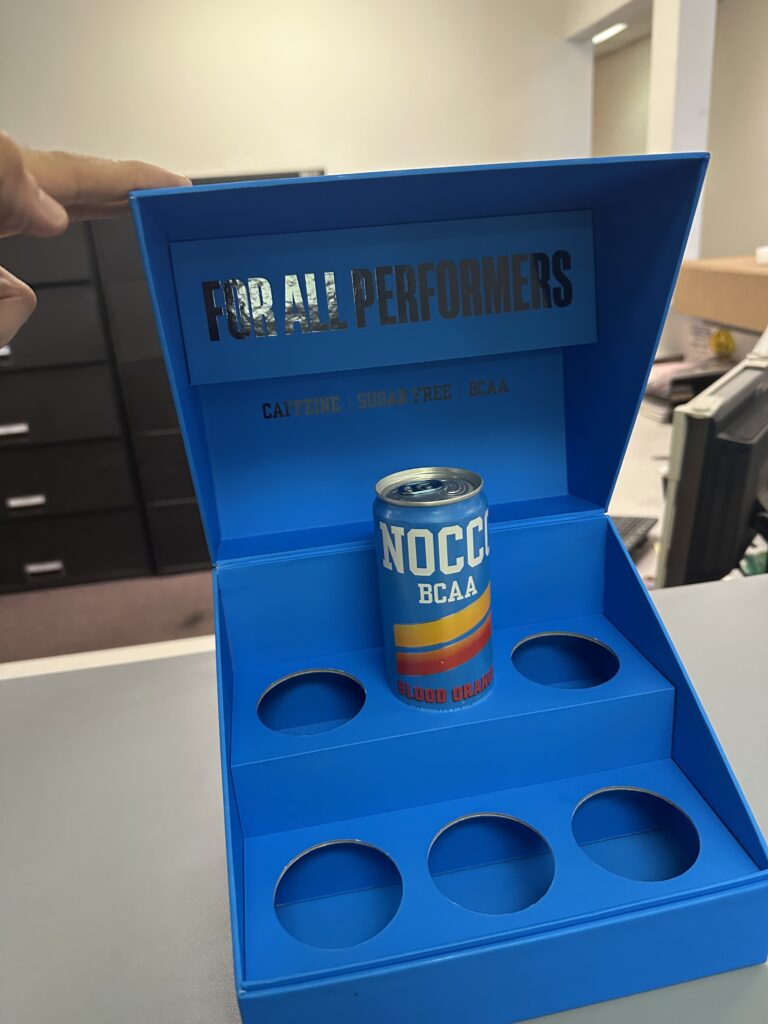

*Images above show a physical sample of NOCCO’s premium rigid box with a hinge and inserts*

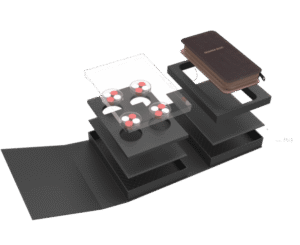

*Images above show a digital sample of NOCCO’s premium rigid box with a hinge and inserts*

*Image above show NOCCO’s sent out card, which is attached to the top of the box*

Implementation: Timeline & Execution

- Step 1: Backward planning ensured artwork deadlines aligned with production.

- Step 2: The Brown Packaging design team worked quickly to finalize the structure and provide die lines.

- Step 3: The client was highly responsive in providing artwork and approving designs, keeping the project on schedule.

Challenges & Adjustments

🚧 Foam-Free Protection – The initial prototype allowed too much movement, so an additional shelf was incorporated to stabilize the cans.

🚧 Box Closure Issues – Adjustments were made to ensure a clean and secure closure.

🚧 Tight Timeline – Rapid approvals were required to meet the three-week deadline, but collaboration between Brown Packaging and NOCCO ensured success.

Outcome: Results

- Premium Branding: A sleek, high-end design that enhanced NOCCO’s marketing campaign.

- Eliminated Foam: A sustainable and efficient structural solution without compromising product protection.

- On-Time Delivery: The custom packaging was designed, tested, and produced within the tight deadline.

*Images above show a physical sample with print of NOCCO’s premium rigid box with a hinge and inserts*

Sales Representative Contact Information

Alex Vom Steeg

Account Manager

📧 Email: alex@brownpackaging.com

📞 Phone: (714) 300-0650

Case Studies: Hammer & Anvils Hammers & Anvils: Kickstarter Game Project Description Our friends at Grim Tavern Games came to us with a new idea – a Kickstarter funded game

Case Studies: Quadrabloc Nature’s Path to Pain Relief: Quadrabloc – Presented by Gradient Medical & Brown Packaging The Challenge Gradient Medical brought one of our favorite projects to us, when they

Case Studies: Bedigami The First 100% Corrugated Bed Platform – Presented by Nest Bedding & Packaging Design Center The Challenge Nest Bedding came to us with a very unique and fun

Home » Case Study: NOCCO – Premium Rigid Box

Case Studies: Bedigami The First 100% Corrugated Bed Platform – Presented by Nest Bedding & Packaging Design Center The Challenge Nest Bedding came to us with

Case Studies: Hammer & Anvils Hammers & Anvils: Kickstarter Game Project Description Our friends at Grim Tavern Games came to us with a new idea

Case Studies: Quadrabloc Nature’s Path to Pain Relief: Quadrabloc – Presented by Gradient Medical & Brown Packaging The Challenge Gradient Medical brought one of our favorite