Home » Bundle Packaging: Everything You Need to Know

Bundle Packaging: Everything You Need to Know

When it comes to marketing and selling products, presentation matters. Bundle packaging is a clever and effective strategy that many businesses use to enhance their products’ appeal and value. Whether you’re a retailer, e-commerce business, or a manufacturer, understanding the art of bundle packaging can make a significant difference in your sales and customer satisfaction. In this blog, we’ll delve into the world of bundle packaging, exploring what it is, its benefits, and how to create effective bundles that resonate with your target audience.

What is Bundle Packaging?

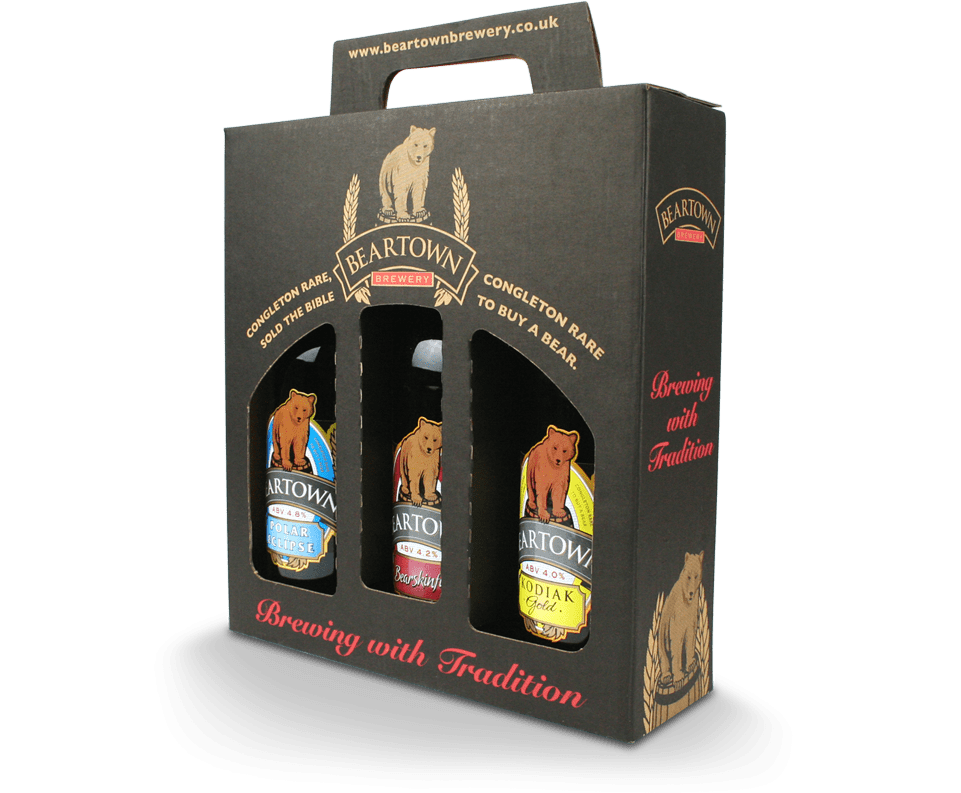

Bundle packaging, also known as product bundling, is the practice of grouping together multiple related products or services into a single package for sale. Instead of selling each item individually, businesses package them together as a bundle, often offering it at a discounted price or with added value. This packaging strategy aims to entice customers to purchase more and enhance their overall shopping experience.

The Benefits of Bundle Packaging

Bundle packaging offers a range of advantages for both businesses and consumers:

Increased Sales:

One of the primary benefits of bundle packaging is its potential to boost sales. Customers are more likely to purchase a bundle of related items if it offers them better value compared to buying each item separately. This can lead to an increase in the average transaction value.

Clear Value Proposition:

Bundles provide a clear value proposition to customers. They can see that by purchasing the bundle, they are getting a deal or receiving added value, which can be a powerful motivator for purchase.

Enhanced Customer Experience:

Customers appreciate convenience. Bundling complementary products together can save them time and effort in finding and purchasing individual items. This convenience can lead to improved customer satisfaction and loyalty.

Inventory Management:

For businesses, bundle packaging can help manage inventory effectively. It allows you to bundle slower-moving products with more popular ones, helping to clear out older stock and improve cash flow.

Competitive Advantage:

Creating unique and compelling bundles can set your business apart from competitors. It allows you to differentiate your offerings and attract customers seeking a comprehensive solution.

How to Create Effective Bundles

Creating successful bundle packages requires careful planning and consideration. Here are some steps to guide you:

Understand Your Audience:

Start by understanding your target audience’s needs and preferences. What products or services are they likely to buy together? What problems can your bundles solve for them?

Choose Complementary Products:

Select products that naturally complement each other. They should enhance the value of the bundle and make sense to the customer. For example, a camera bundle could include lenses, a tripod, and a camera bag.

Pricing Strategy:

Determine the pricing strategy for your bundles. Typically, bundles are priced lower than the total cost of purchasing each item separately, offering customers a discount. However, ensure that your pricing still allows for a reasonable profit margin.

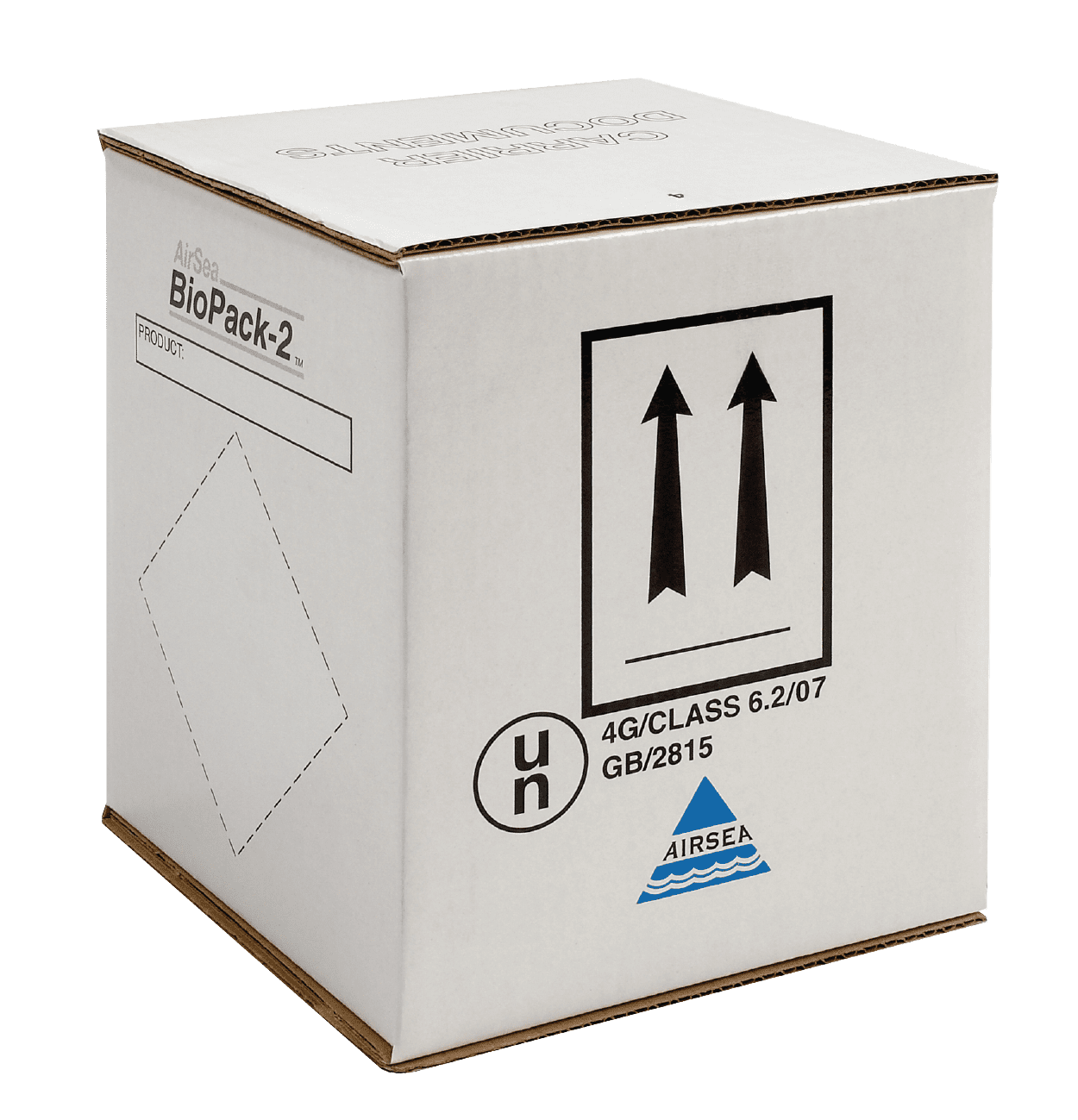

Packaging Design:

Invest in attractive and informative packaging design. The packaging should clearly communicate what’s included in the bundle and its value proposition. High-quality packaging enhances the perceived value of the bundle.

Marketing and Promotion:

Promote your bundles through various marketing channels, both online and offline. Highlight the benefits of purchasing the bundle, such as cost savings or convenience. Use visuals and descriptions that resonate with your target audience.

Monitor and Adjust:

Track the performance of your bundles. Analyze sales data, customer feedback, and return on investment. Make adjustments as needed to optimize your bundle offerings.

Examples of Successful Bundle Packaging

- Tech Gadgets Bundle: A bundle that includes a smartphone, wireless earbuds, and a phone case, all for a lower price than buying them individually.

- Cooking Essentials Bundle: A bundle of kitchen appliances like a blender, food processor, and a set of high-quality knives, perfect for aspiring chefs.

- Beauty and Skincare Set: A bundle containing skincare products, makeup, and a cosmetic bag, offering customers a complete beauty solution.

- Fitness Starter Pack: A bundle with workout equipment, a fitness tracker, and a subscription to a fitness app, targeting fitness enthusiasts.

In Conclusion

Bundle packaging is a powerful strategy that can benefit both businesses and customers. It offers convenience, value, and the potential for increased sales. By understanding your audience, choosing the right products, and effectively marketing your bundles, you can tap into the potential of bundle packaging to enhance your brand and drive revenue. So, get creative, bundle up, and watch your sales soar!

If you are interested in bundle packaging, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Bundle Packaging: Everything You Need to Know