Home » Balancing Safety with Space Optimization in Packaging

Balancing Safety with Space Optimization in Packaging

In the packaging industry, achieving the perfect balance between ensuring product safety and optimizing space is a complex yet vital goal. This blog post explores various strategies and considerations for businesses aiming to navigate this balance effectively.

Understanding the Challenge

The intricacies of packaging require a careful balance. While it’s crucial to protect the product, it’s equally important to design packaging that is space-efficient for storage and transportation. This balance impacts not only cost-effectiveness but also environmental sustainability.

Prioritize Product Safety

The first and foremost consideration in packaging should always be the safety of the product. Understanding the product’s vulnerability, selecting quality materials, and conducting thorough testing are essential steps to ensure that the packaging adequately protects its contents.

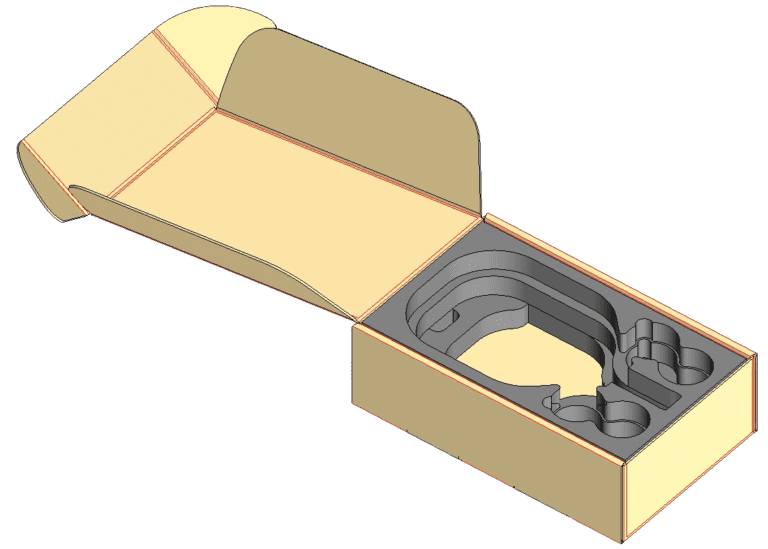

Design for Space Efficiency

Effective packaging design maximizes space utilization without compromising safety. Compact and customized designs, along with modularity, can significantly enhance space efficiency in both storage and transportation.

Implement Smart Packing Techniques

Smart packing involves using strategic layering, padding, and multi-functional components to protect the product. These techniques aim to provide maximum safety with minimal material usage.

Explore Advanced Materials and Technologies

Innovative materials and technologies can offer improved protection with less bulk. The integration of smart sensors and advanced protective materials can revolutionize how products are packaged and monitored.

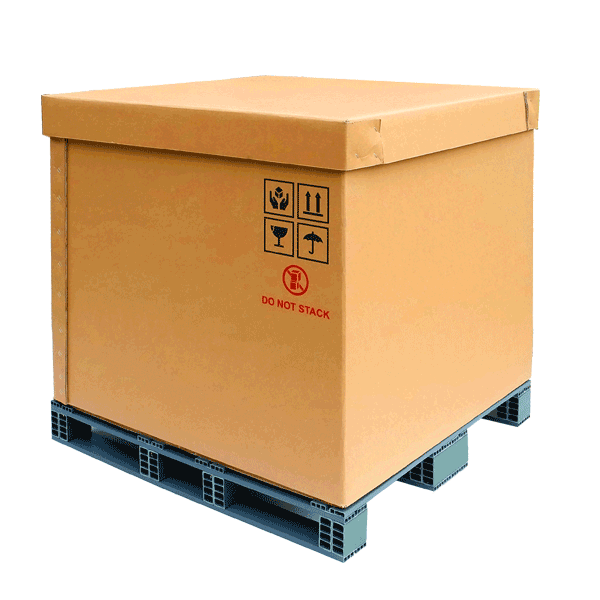

Optimize for Storage and Transportation

Optimizing packaging for storage and transportation involves designing for stackability and considering pallet optimization. This ensures that the packaging fits efficiently in warehouses and during transit, reducing transportation costs and space requirements.

Conduct a Cost-Benefit Analysis

Regularly assessing the costs associated with packaging materials and potential product damage is crucial. This analysis should weigh the costs of robust packaging against savings from reduced damage rates and improved space utilization.

Sustainability Considerations

Sustainable packaging is not just an environmental responsibility; it also contributes to the safety-space balance. Eco-friendly materials and strategies that minimize waste and promote recycling can play a significant role in this balance.

Continuous Improvement and Adaptation

Establishing a feedback loop for continuous data gathering and staying informed about industry trends are essential for adapting and improving packaging strategies. This approach ensures that packaging remains effective and efficient over time.

Conclusion

Balancing safety with space optimization in packaging is a dynamic and ongoing process. By focusing on these key areas and maintaining a flexible approach to packaging design and materials, businesses can achieve a packaging strategy that effectively protects their products while optimizing space and resources.

If you are interested in packaging solutions, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Balancing Safety with Space Optimization in Packaging

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Retail packaging must do two jobs at once—catch the shopper’s eye while protecting the product through the supply chain. Too much focus on graphics can

In the world of shipping and storage, the term “Gaylord box” often comes up, especially in industries that deal with bulk materials and goods. But