Home » A Comprehensive Guide to Polyurethane Foam for Packaging

A Comprehensive Guide to Polyurethane Foam for Packaging

When it comes to protecting fragile or valuable items during shipping or storage, the choice of packaging material can make all the difference. Polyurethane foam is a versatile and highly effective material that has gained popularity in the world of packaging. In this comprehensive guide, we will explore what polyurethane foam is, its properties, benefits, and various applications in packaging.

Introduction to Polyurethane Foam

Polyurethane foam is a versatile polymer material that is widely used in various industries, including construction, automotive, and of course, packaging. It is created through the reaction of polyols and isocyanates, resulting in a foam with a wide range of properties, making it suitable for diverse applications.

In packaging, polyurethane foam is valued for its ability to provide cushioning and protection to fragile and sensitive items, effectively preventing damage during transit.

Properties of Polyurethane Foam

Physical Properties

- Flexibility: Polyurethane foam is highly flexible, allowing it to conform to the shape of the object it is protecting, ensuring a snug and secure fit.

- Density: It is available in various densities, ranging from low-density foam for cushioning to high-density foam for structural support.

- Compression Strength: Polyurethane foam can withstand a wide range of compressive forces, making it ideal for items of varying weights and sizes.

- Thermal Insulation: It offers some degree of thermal insulation, which can be crucial for products sensitive to temperature changes.

Chemical Properties

- Chemical Resistance: Polyurethane foam exhibits resistance to many chemicals, which can protect items from exposure to corrosive substances.

- Moisture Resistance: It is inherently resistant to moisture, helping to prevent damage due to water or humidity exposure.

Benefits of Using Polyurethane Foam in Packaging

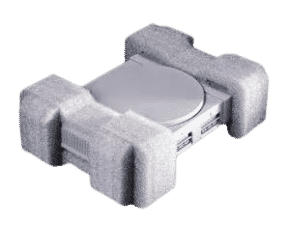

- Shock Absorption and Impact Resistance: One of the primary benefits of polyurethane foam is its exceptional shock absorption and impact resistance. It effectively absorbs and dissipates energy from impacts, reducing the risk of damage to packaged items.

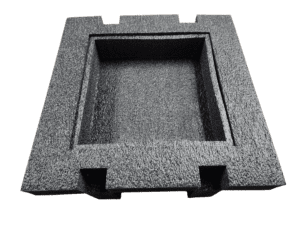

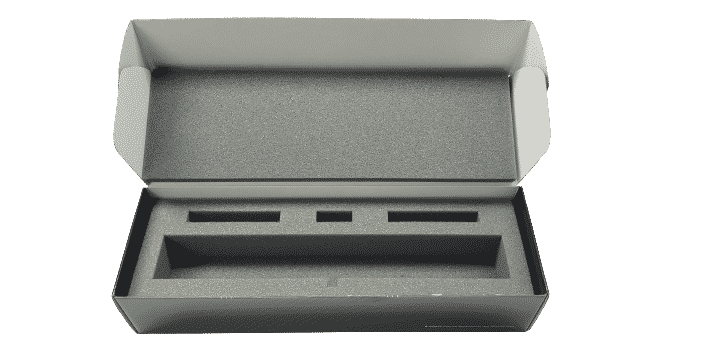

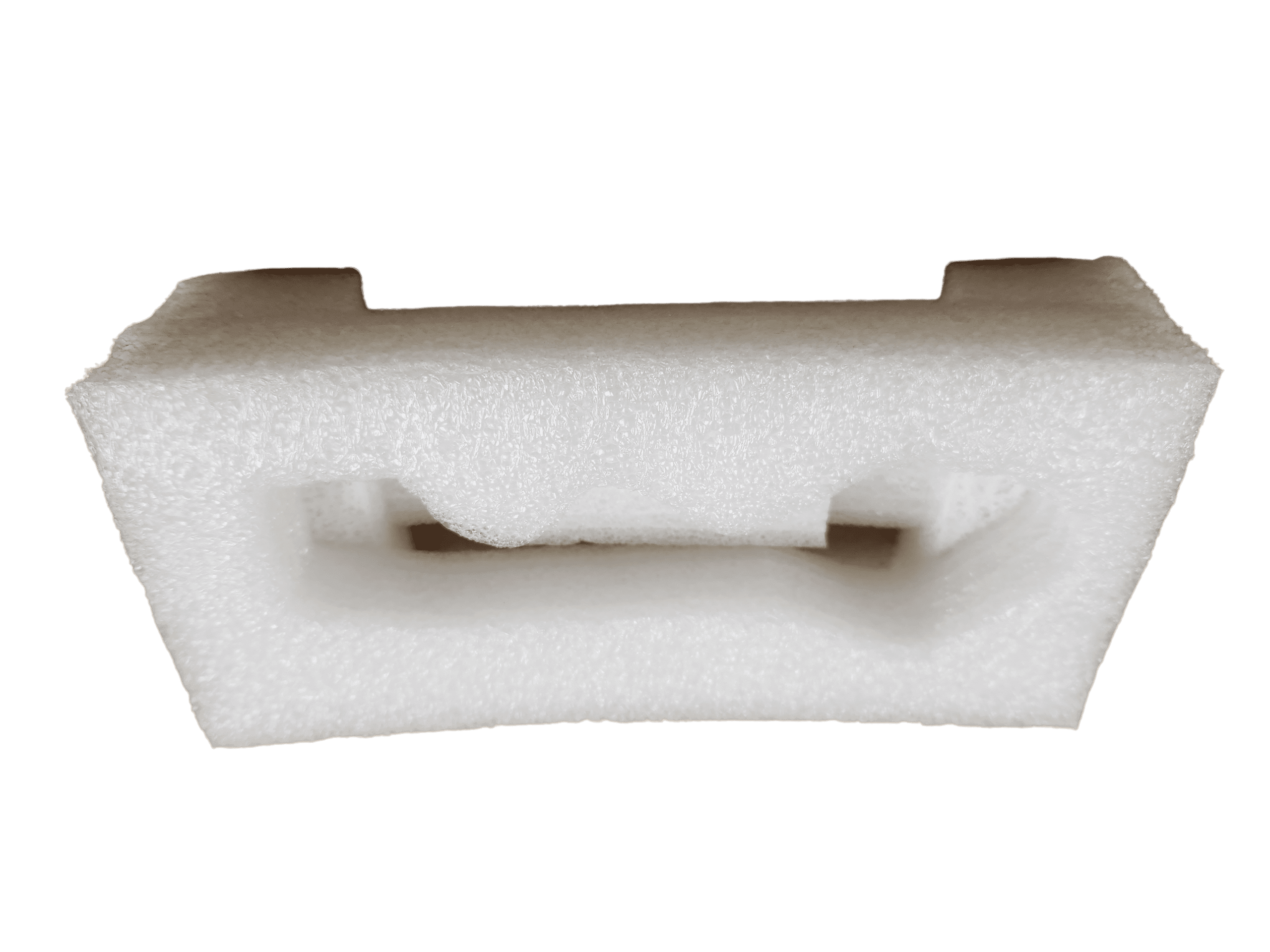

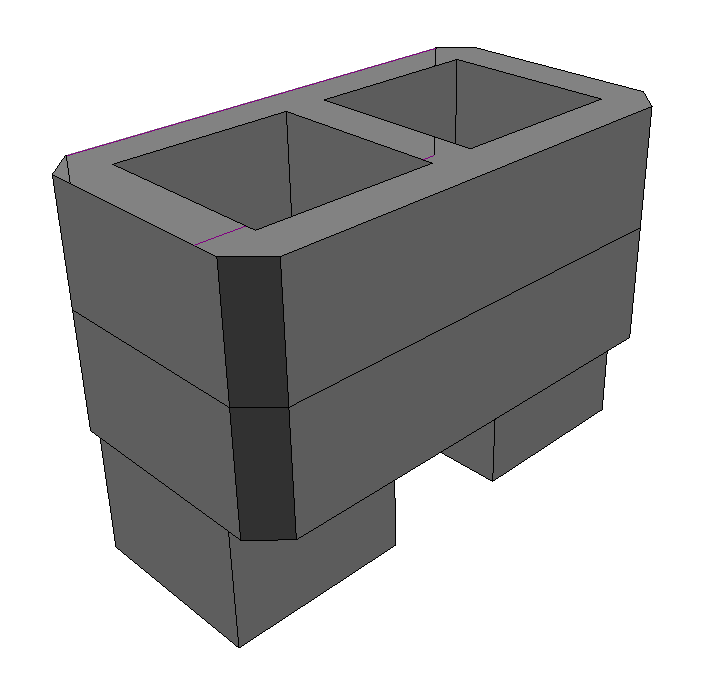

- Customization and Versatility: Polyurethane foam can be easily cut and shaped to fit the specific dimensions of the item being packaged. This versatility allows for precise and tailored protection.

- Moisture Resistance: Its inherent resistance to moisture makes polyurethane foam an excellent choice for products that are sensitive to humidity or may encounter wet conditions during shipping.

- Lightweight and Space Efficiency: Polyurethane foam is lightweight, helping to minimize shipping costs. Its ability to compress and expand as needed also makes it space-efficient.

Applications of Polyurethane Foam in Packaging

- Electronics Packaging: Polyurethane foam is commonly used to protect delicate electronics such as laptops, smartphones, and components during transit.

- Medical Device Packaging: Medical devices, which often have sensitive components, benefit from polyurethane foam’s protective properties.

- Automotive Parts Packaging: Automotive parts, from small components to large body panels, are safeguarded during shipping with polyurethane foam.

- Fragile Goods Packaging: Fragile items like glassware, ceramics, and artworks are frequently packed with polyurethane foam to prevent breakage.

Choosing the Right Polyurethane Foam

When selecting polyurethane foam for packaging, consider the following factors:

- Density: Choose the foam density based on the weight and fragility of the item. Heavier or delicate items may require higher-density foam for better protection.

- Hardness: The foam’s hardness or firmness should match the level of cushioning needed. Softer foams offer more cushioning, while firmer foams provide better support.

- Size and Shape: Customize the foam’s size and shape to ensure a snug fit around the item.

Manufacturing and Customization

Polyurethane foam can be tailored to meet specific packaging needs. Manufacturers can create custom foam inserts, shapes, and sizes to perfectly fit the item being packaged.

If you are interested in polyurethane foam, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » A Comprehensive Guide to Polyurethane Foam for Packaging

Packaging plays a crucial role in protecting products during transit and storage. Among the various materials used for packaging, polyethylene foam stands out as an

When working with thick foam materials in the packaging industry, it’s important to be aware of the natural outcomes of the die-cutting process—one of the

In the world of e-commerce and supply chain management, the need for reliable packaging materials cannot be overstated. From the careful encasing of fragile items