Home » A Buyer’s Guide to Roll Stock

A Buyer’s Guide to Roll Stock

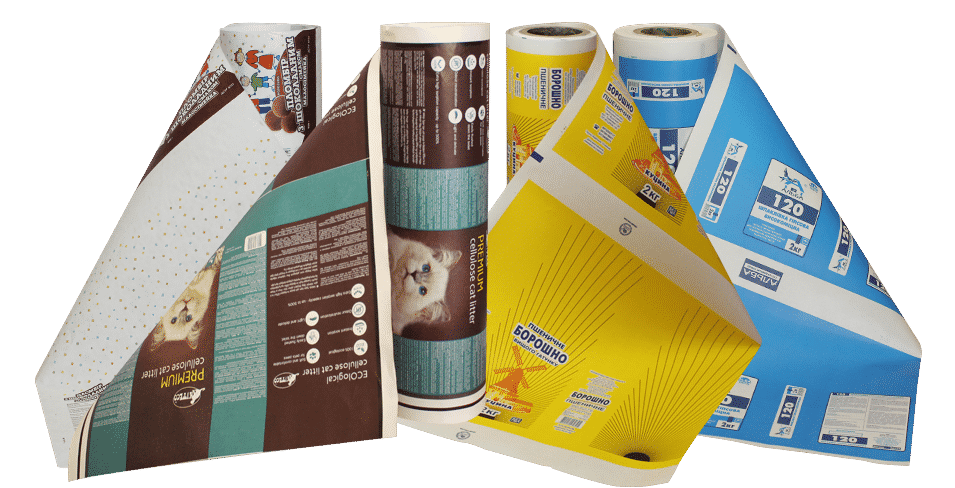

In the world of packaging, roll stock, also referred to as candy wrappers or snack wrappers, is a versatile and essential component. It refers to a continuous sheet of flexible material wound into a roll, used in various packaging applications. Roll stock materials come in a wide range of options, each designed to meet specific packaging requirements. Whether you are a seasoned packaging professional or a newcomer to the field, this buyer’s guide to roll stock will help you navigate the complexities of selecting the right material for your packaging needs.

Understand Your Packaging Requirements

Before diving into the specifics of roll stock materials, it’s crucial to understand your packaging requirements. Ask yourself the following questions:

- What type of product are you packaging?

- What are the dimensions and weight of your product?

- Is your product sensitive to environmental factors like moisture, oxygen, or light?

- What is the expected shelf life of your product?

- Do you require printing or branding on the packaging material?

- What is your budget for packaging materials?

By answering these questions, you’ll gain a clearer picture of your packaging needs and be better equipped to choose the right roll stock material.

Types of Roll Stock Materials

Roll stock materials come in various types, each offering unique characteristics and benefits. Here are some common roll stock materials:

Flexible Films:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polyester (PET)

- Nylon (PA)

Flexible films are suitable for a wide range of products, from food to electronics. They offer excellent barrier properties and are customizable for printing.

Foil Laminates:

- Aluminum foil laminated with various substrates

Foil laminates provide exceptional barrier properties against moisture, light, and oxygen. They are often used for perishable food items and pharmaceuticals.

Paper-Based Roll Stock:

- Kraft paper

- Coated paper

Paper-based roll stock is eco-friendly and ideal for products where a natural or rustic appearance is desired.

Specialty Films:

- Metallized films

- Biodegradable films

- Retort pouch films

Specialty films cater to unique packaging needs, such as high gloss, sustainability, and resistance to high-temperature processing.

Barrier Properties

Consider the barrier properties required for your product. For example, if you are packaging perishable goods, you’ll need materials with excellent moisture and oxygen barrier properties. Foil laminates and certain specialty films are often preferred for such applications.

Printing and Branding

If branding and aesthetics are crucial for your product, choose roll stock materials that offer excellent printability. Flexible films and paper-based materials are typically easier to print on, allowing for vibrant graphics and branding.

Environmental Impact

In today’s environmentally conscious world, it’s essential to consider the environmental impact of your packaging materials. Biodegradable films and sustainable materials are excellent choices for eco-friendly packaging.

Budget Constraints

Budget constraints are a significant factor in the decision-making process. While high-performance materials may offer superior properties, they can also be more expensive. Balance your budget with your packaging requirements to find the most cost-effective solution.

Regulatory Compliance

Ensure that your chosen roll stock material complies with relevant industry regulations and standards. This is particularly important for packaging in the food and pharmaceutical industries, where strict guidelines are in place.

Supplier Selection

Choose a reliable and reputable roll stock supplier. Look for a supplier with a proven track record of delivering high-quality materials on time and within budget.

If you are interested in packaging your products with roll stock, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » A Buyer’s Guide to Roll Stock

Gusseted bags are designed with extra folds of material at the sides or bottom to increase capacity and structural support. This feature makes them ideal

When it comes to pouch packaging, the material and finish play a crucial role in the overall functionality, aesthetics, and consumer appeal of the product.

A pouch is a flexible packaging product which is made up of layers of plastic film, metalized, barrier film and other materials. Typically they are