Home » A Buyer’s Guide to Packaging Fragile Products in RETT Boxes

A Buyer’s Guide to Packaging Fragile Products in RETT Boxes

When it comes to packaging fragile products, the choice of packaging materials and techniques plays a critical role in ensuring your delicate items reach their destination unscathed. Roll End Tuck Top (RETT) boxes offer a versatile solution for safeguarding fragile treasures during transit. In this buyer’s guide, we will delve into the essential steps and strategies for effectively packaging fragile products using RETT boxes, helping you make an informed choice to protect your delicate items.

Selecting the Right RETT Box for Fragile Items

The first step in packaging fragile products is choosing the appropriate RETT box. As a buyer, consider the following factors:

- Size: Ensure the box is the right size for your fragile items, allowing for a snug fit without excess space that could lead to movement during transit.

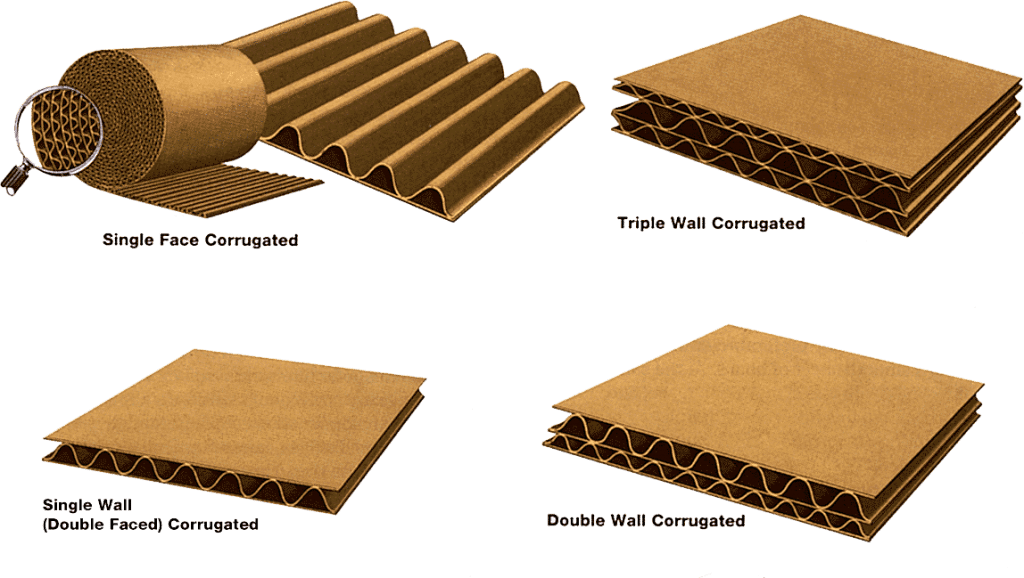

- Stronger Material: Opt for double-wall RETT boxes to ensure added strength and protection, especially when dealing with particularly fragile items.

- Internal Packaging: Depending on the fragility of your items, you may need additional internal packaging materials such as bubble wrap, foam inserts, or custom dividers.

Wrapping and Cushioning Your Fragile Items

- Bubble Wrap: As a buyer, it’s essential to procure multiple layers of bubble wrap to wrap your fragile items. Ensure that all surfaces are covered, and pay special attention to any delicate protrusions or corners.

- Foam Padding: For extra protection, consider purchasing foam padding to wrap around your items. You can choose between cutting foam sheets to size or acquiring pre-cut foam inserts for a snug and cushioned environment.

- Secure with Tape: Be sure to secure the bubble wrap and foam padding in place using packaging tape. Verify that there are no loose edges or corners that could get caught during transit.

Positioning Your Fragile Items in the RETT Box

- Center Placement: As a buyer, take care to place the wrapped and cushioned fragile items in the center of the RETT box. Ensure that there is a buffer of space between the products and the box walls.

- Layer of Void Fill: Add a layer of void fill material, such as packing peanuts or air pillows, around the items to further absorb shocks and vibrations during transportation.

Sealing and Securing the RETT Box

Tuck Top Closure: As a buyer, you should utilize the tuck top closure and cherry locks feature of the RETT box, folding the tuck flaps neatly. This secure closure prevents accidental openings during handling and transport.

Sealing Tape: Seal the top of the box using high-quality packaging tape. Make certain that all seams are well-secured and consider using tape to reinforce the corners for added stability.

Labeling and Fragile Warning for Buyers

- Labeling: It is crucial to label the box clearly as “Fragile” on all sides, using bold and easily visible lettering. This notifies handlers to exercise caution when dealing with your fragile items.

- Orientation Arrows: Buyers may also consider adding orientation arrows to indicate the proper upright position of the box, further reducing the risk of mishandling.

Properly Packing Multiple Fragile Items for Buyers

When purchasing RETT boxes to package multiple fragile items, buyers should consider these additional tips:

- Separate and Wrap: Ensure that each fragile item is individually wrapped, cushioned, and separated from the others to prevent contact and potential damage.

- Layering: Utilize dividers or layers of void fill between the items to create a protective barrier.

- Staggered Placement: Stagger the placement of items within the box to distribute weight evenly and reduce the risk of breakage.

Conclusion for Buyers

As a buyer, choosing the right RETT boxes and following these packaging steps and strategies can significantly reduce the risk of damage to your fragile products during transit. By taking these precautions and selecting the appropriate packaging materials, you can have confidence that your delicate items will reach their destination in pristine condition, ensuring customer satisfaction and brand reputation.

If you are interested in packaging fragile products with roll end tuck end boxes, then partner with Brown Packaging today to get started.

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Home » A Buyer’s Guide to Packaging Fragile Products in RETT Boxes

Corrugated boxes have been a staple in packaging and shipping for decades, and they continue to play a crucial role in various industries. As we

In recent years, sustainability has become a key focus in various industries, including packaging. As companies strive to minimize their environmental footprint, innovative solutions are

In the world of packaging, ensuring the safety and integrity of products during transit is paramount. This is where the corrugated box drop test comes