Home » What is a Packaging Insert?

What is a Packaging Insert?

Custom box inserts are used to ensure your products are secure inside your box throughout the supply chain. They are used to keep your product safe as well as organized, especially if you have many products in one box. Having packaging inserts will give an impressive presentation. When a customer opens a box and sees the products organized in an insert, they will overall have a better impression of your brand.

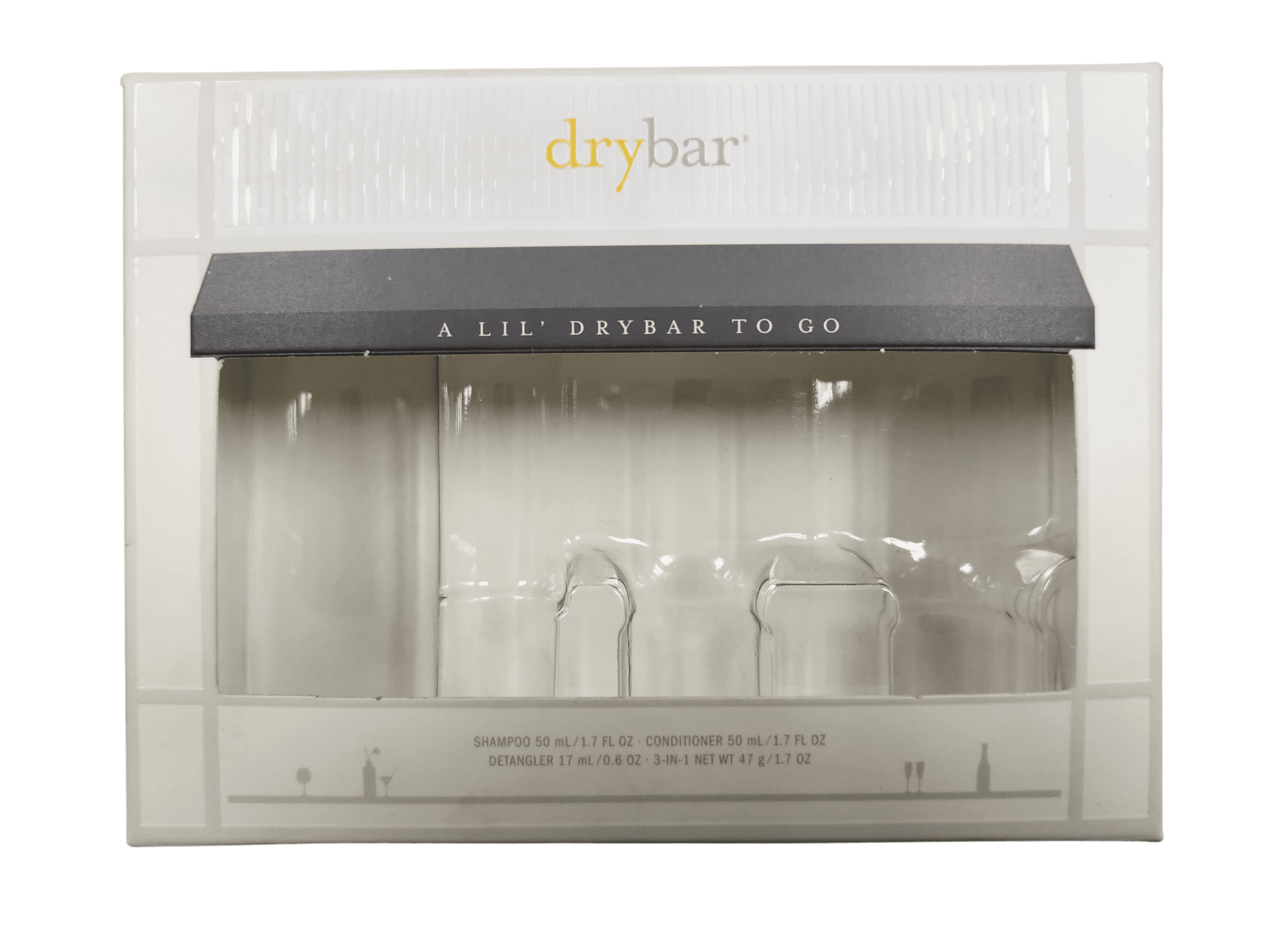

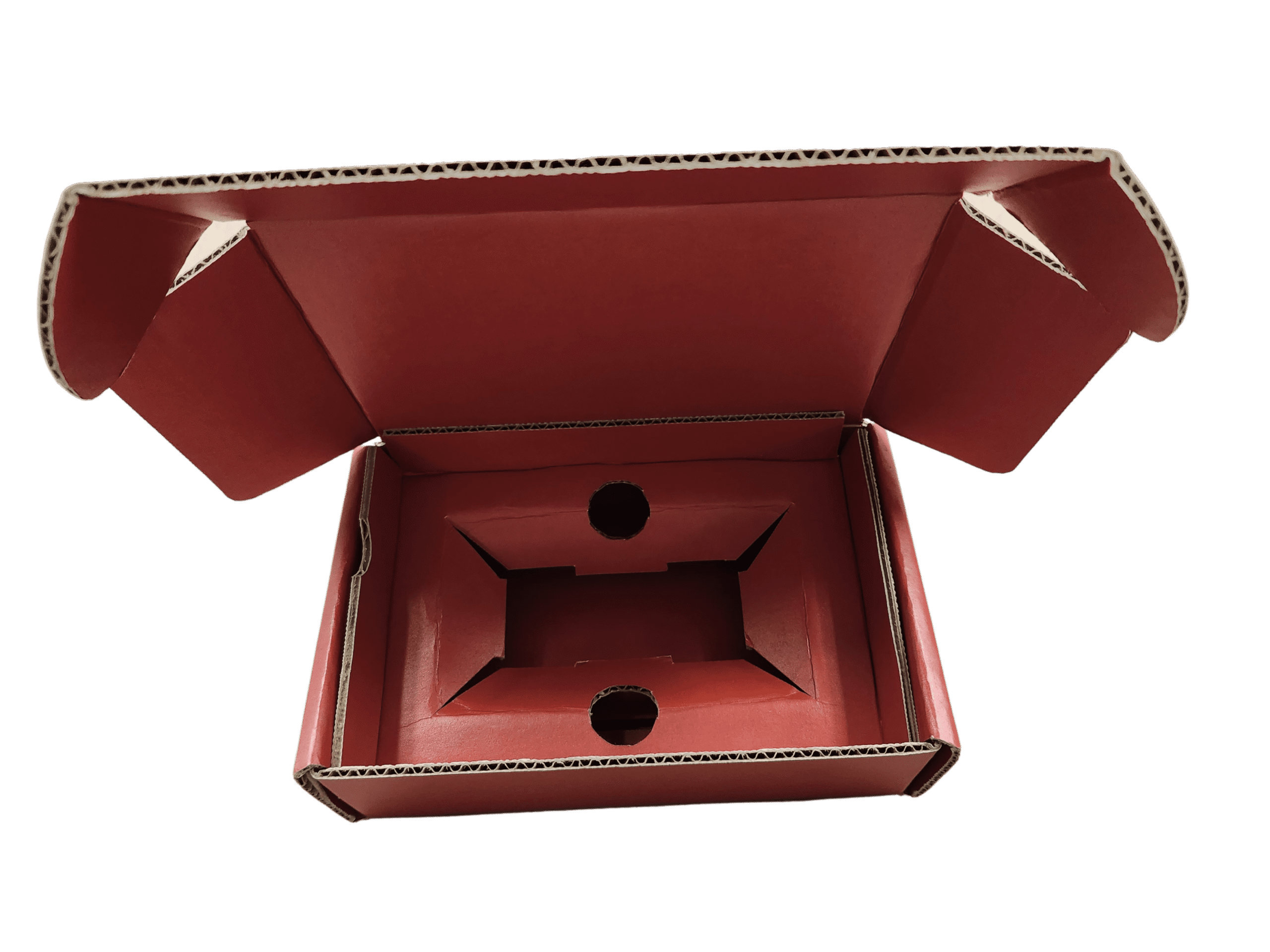

Regular packaging inserts are used more for retail applications as they showcase the product, while partition inserts are usually used for shipping products. Regular inserts hold a product in place, usually just at the bottom of the product while still showcasing the product itself.

As for partitions, they cover almost the whole product to ensure it stays protected. Although it is not as eye catching as regular inserts, it is necessary depending on the product you are packaging. Partition inserts are best for bottles and glass due to its protective qualities.

Different Types of Packaging Inserts:

Packaging inserts vary by material, which provides them with certain properties, which can make them ideal for certain packaging applications. By understanding the difference between these types of packaging inserts, you can make more informed decisions on how to package, display and protect your product:

Chipboard

Corrugated

Foam

Thermoform

What are Chipboard Inserts?

Chipboard or commonly known as paperboard is made from an interlaced network of cellulose fibers and is best used for holding small and lightweight products. It is the thinner of custom box inserts, and is the cheapest option. It will not offer the best protection compared to other inserts, but depending on what your product is, it could be the perfect fit. These inserts are best for items such as cosmetics, office supplies, food, and other light weight products.

Color and Design:

- Standard white

- Natural Kraft

- Customizable with color and design

- Packaging insert or partition

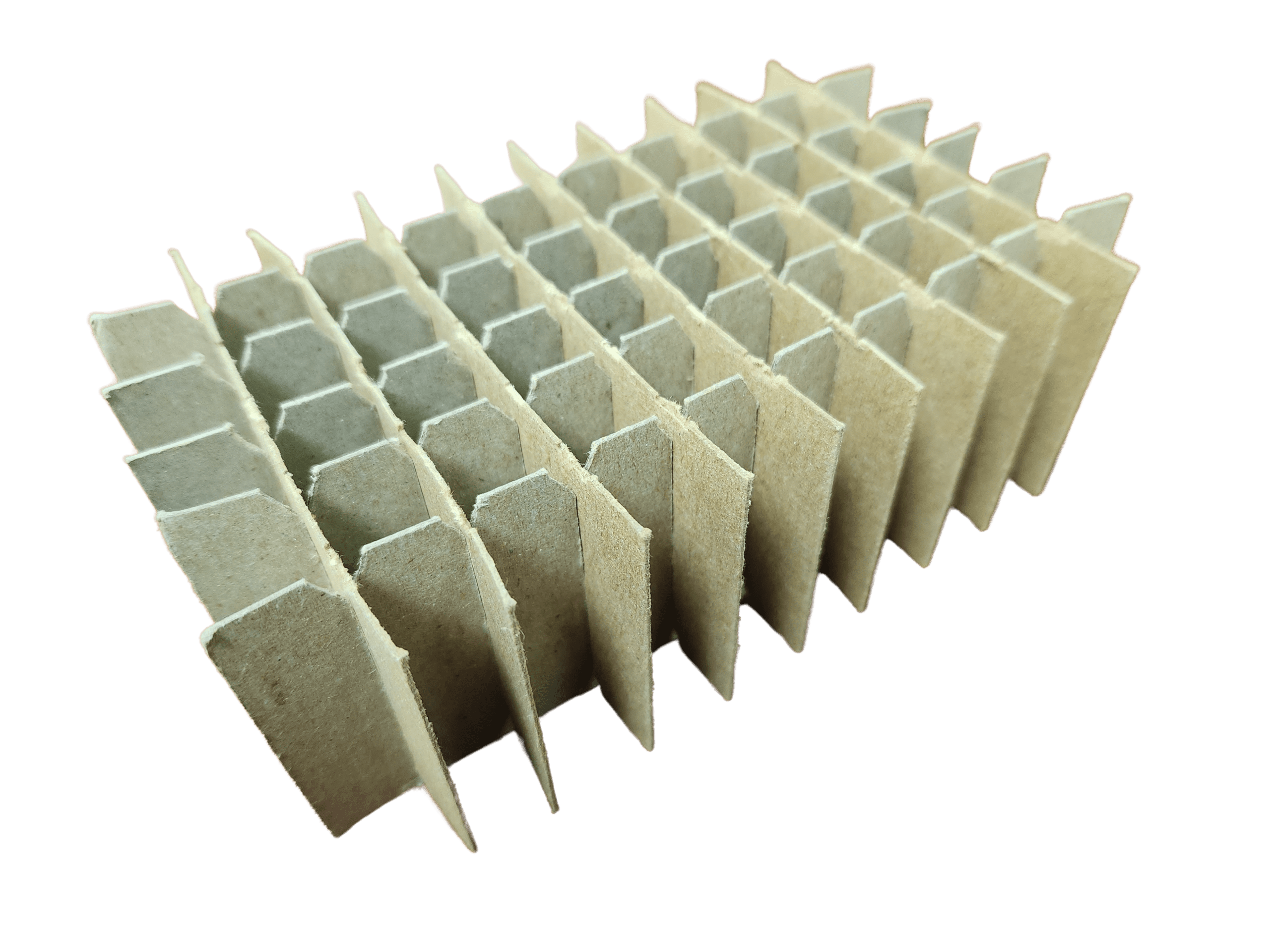

What are Corrugated Inserts?

Corrugated comes in a wide range of strengths, size, and support. It is made with two outside paper layers and an inner flute layer, creating a sandwiched design. Based on the needed support more layers can be added to corrugated material to help improve its strength. These inserts are cost effective and eco-friendly. This material is best to hold medium weight products that need protection or have a lot of items in one box.

Color and Design:

- Standard white

- Natural Kraft

- Customizable with color and design

- Packaging insert or partition

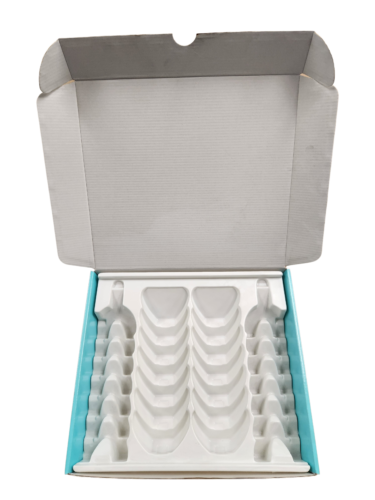

What are Molded Pulp Inserts?

Molded pulp is made up of a variety of materials like recycled paper and natural fiber that are formed in molds. Molded pulp can be manufactured in a few different ways, which are dry press, wet press, and processed. It is not usually printed on due to the surface texture, but it can have coatings added on top to create a more luxury appearance. This insert can have a high startup cost due to the price of the tooling and molding. It is molded to the product making it durable for packaging items like beverage and cosmetics.

Materials used:

- Molded Pulp: Made from recycled paper and natural fibers

- Bagasse: Made from remains after crushing sugarcane and sorghum stalks

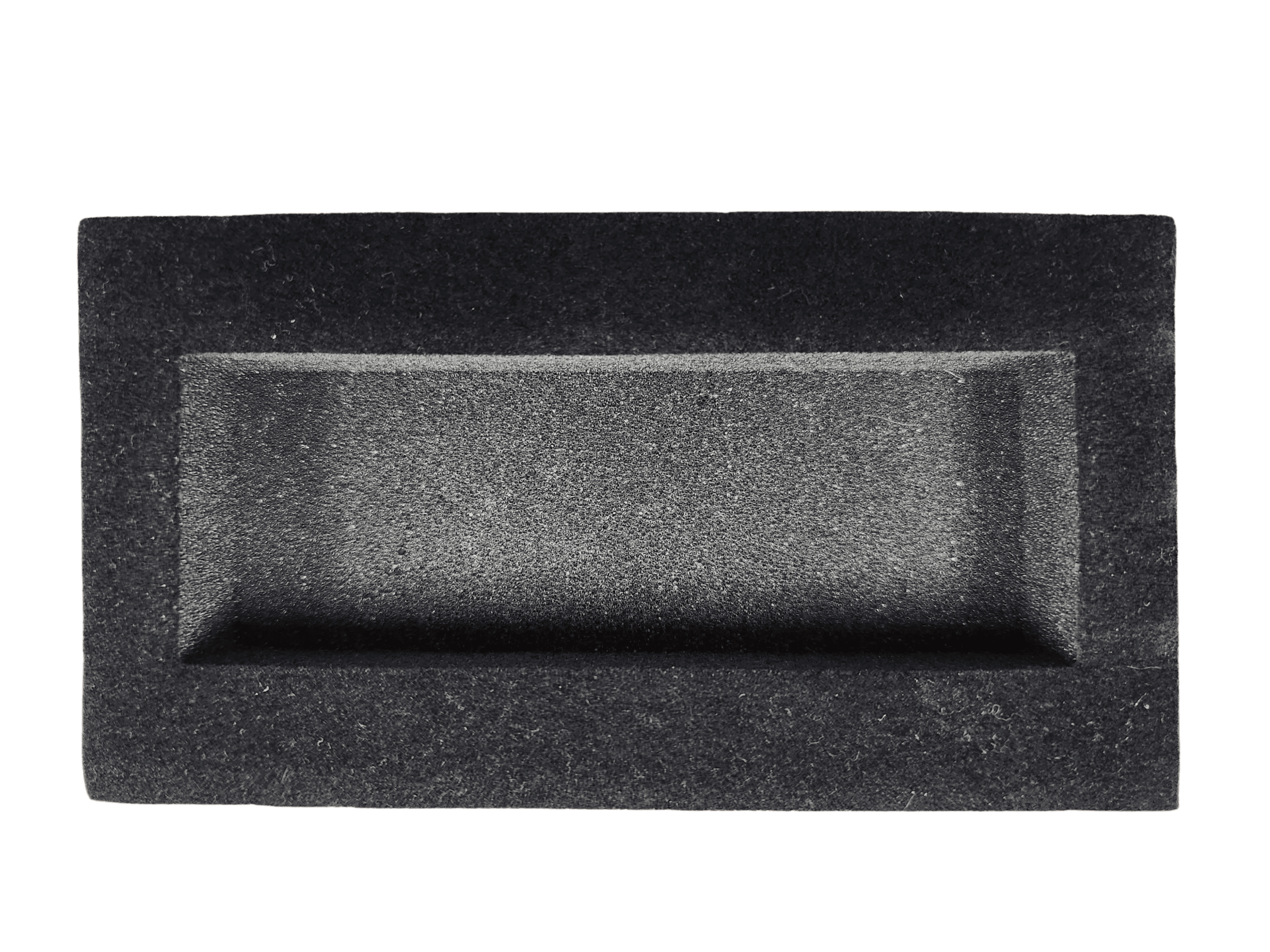

What are Foam Inserts?

Foam inserts are made from polymer matrix that combines heat, pressure, and gas bubbles to create solid foam. It is meant for holding the heaviest items and protecting the most fragile. These inserts are super lightweight and the most resistant to wear and tear. This insert can be created in many shapes, sizes, and designs. It offers maximum cushioning, lightweight ability, durable material, and it is perfectly fitted to products.

Polyethylene

Materials Used:

- Polyurethane (Ethers/Esters): Is superior in durability and is used in construction, medical, electronic devices, and industrial applications.

- Polyethylene: Comes in a variety of colors and density and used to protect electronic devices such as computers, auto parts and hard drives.

- Expanded Polystyrene: Offers high compression and thermal properties and is used for inner package support, box liners and pads

What are Thermoform Inserts?

Thermoform inserts are sturdy, rigid, and can hold a variety of items. They are a low weight option made from plastic materials. In order to make a thermoform insert, a mold must be created to fit your product and packaging. Then using heat and pressure the plastic is shaped to fit the mold. Although one of the sturdier inserts, it is also more costly. Like the molded pulp, thermoform has an expensive startup cost for tooling and molding. These inserts are best for electronic, industrial and medical applications.

Materials Used:

- PET: Strong and light weight clear thermoplastic

- HDPE: Durable and strong with matte finish

- PVC: Flexible and heat resistant

- PP: High strength plastic with food safe capabilities and can be made with recycled material

- PS/HIPS: Best for heavy products

- PETG: Durable and high resistance to chemicals, heat, and water

- PC: Heat resistant, good electrical insulation properties

Summary: Selecting the Right Packaging Inserts

Inserts are important when it comes to packaging your products. They will keep your products safe and organized from production to the end point. It will give strong protection to ensure there is no breakage or issues. It also gives the ability to ship multiple products together ensuring each product stays in its respective location for unboxing. Overall investing in inserts will enhance the customers experience when receiving your product. There are many types of packaging inserts, finding the one that fits your business needs is important.

If you need assistance in choosing which insert would be best for your business needs, please contact Brown Packaging today and one of our packaging specialists will assist you.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » What is a Packaging Insert?

In the world of retail and e-commerce, packaging isn’t just about protecting products; it’s an essential part of the overall customer experience. One effective strategy

In the world of e-commerce, packaging is much more than just protection for your products. It has evolved into a vital marketing asset that helps

Corrugated boxes are strong because of their unique construction, which features a fluted corrugated sheet sandwiched between two flat linerboards. This design creates a robust