Home » Designing Folding Cartons for E-Commerce Shipping Durability

Designing Folding Cartons for E-Commerce Shipping Durability

E-commerce exposes folding cartons to more handling points, longer transit times, and harsher mechanical stresses than traditional retail distribution. Designing for these conditions requires careful material selection, structural reinforcement, and testing to ensure the product arrives intact and presentable.

Understanding E-Commerce Transit Hazards

Small-parcel shipping subjects cartons to conditions outside typical retail supply chains:

- Multiple Sorting Touchpoints: Each transfer increases the risk of edge crush and panel denting.

- High Vibration: Long delivery routes and conveyor systems cause sustained shaking.

- Compression Loads: Cartons may be stacked under heavier mixed-weight items in transport.

- Environmental Variability: Temperature and humidity swings in delivery trucks and sorting centers.

(ASTM D4169 simulates these hazards for performance testing.)

Material Selection

- CUK (Coated Unbleached Kraft): Higher tear and puncture resistance, ideal for heavier or rigid products.

- High-Caliper SBS: Provides a smooth print surface while increasing crush resistance.

- Poly-Coated or Moisture-Barrier Boards: Essential for humid climates or cold-chain shipments.

Tip: Avoid over-specifying — choose the lightest grade that meets drop, compression, and vibration requirements.

Structural Reinforcements

- Full Seal End (FSE): Seals both ends for maximum tamper resistance and panel rigidity.

- Auto Bottom: Improves stacking strength while enabling faster manual packing.

- Reinforced Glue Flaps: Wider flaps or added tear-resistant tape in high-stress zones.

- Double-Panel Sides: Layering board at impact-prone edges to reduce corner crushing.

Coatings and Finishes

- Scuff-Resistant Varnish: Maintains appearance after multiple handling points.

- Water-Resistant Coatings: Prevent fiber swelling from rain or condensation.

- Matte Finishes: Reduce visible wear compared to high gloss in transit.

Testing and Validation

- Drop Tests: Simulate handling from waist height at multiple orientations.

- Vibration Testing: Identify structural weaknesses under sustained shaking (ASTM D4728).

- Compression Tests: Ensure cartons can withstand stacking in mixed-weight loads (TAPPI T804).

- Environmental Conditioning: Test under humidity and temperature extremes before market launch.

Cost–Performance Balance

Over-engineering increases per-unit cost and shipping weight. The most durable e-commerce cartons balance material and style to meet ISTA or ASTM testing requirements without exceeding budget targets.

References

ASTM International. (2016). ASTM D4169-16: Standard practice for performance testing of shipping containers and systems. ASTM International. https://doi.org/10.1520/D4169-16

ASTM International. (2016). ASTM D4728-06(2016): Random vibration testing of shipping containers. ASTM International. https://doi.org/10.1520/D4728-06R16

TAPPI. (2017). T 804: Compression test of fiberboard shipping containers. TAPPI Press.

Soroka, W. (2014). Fundamentals of packaging technology (5th ed.). Institute of Packaging Professionals. ISBN: 978-1-930268-37-2

Twede, D., & Goddard, R. (2021). Cartons, crates and corrugated board: Handbook of paper and wood packaging technology (2nd ed.). DEStech Publications. ISBN: 978-1-60595-120-5

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Home » Designing Folding Cartons for E-Commerce Shipping Durability

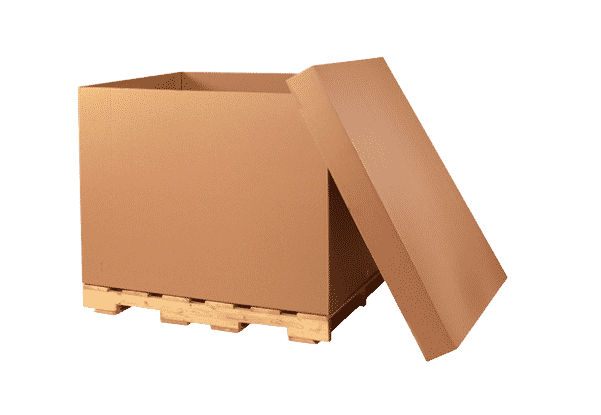

Gaylord containers are large, sturdy boxes used primarily for shipping, storing, and handling bulk materials. Often utilized in industries like manufacturing, agriculture, and retail, these versatile containers are designed to accommodate large volumes of products while providing robust protection. Depending on the specific application, Gaylord containers are available in single, double, and triple wall options, each offering varying degrees of strength and durability. In this blog, we will explore the differences between these options and their practical applications. What Are Gaylord Containers? Gaylord containers, also known as bulk bins or pallet boxes, are large corrugated boxes designed for storing and transporting bulk goods. They are typically mounted on pallets for easy handling with forklifts and other equipment. These containers are highly versatile, accommodating a wide range of materials, including powders, granules, parts, and even irregularly shaped items. Single Wall Gaylord Containers Construction: Single wall Gaylord containers consist of one layer of corrugated cardboard. This layer typically includes a fluted sheet sandwiched between two flat linerboards. Applications: Single wall containers are suitable for lighter materials or products that do not require extensive protection during shipping. They are commonly used for: Lightweight products like plastic parts or textiles Non-fragile items that are not prone to damage Short-distance shipping where minimal handling occurs Benefits: Cost-effective solution for bulk packaging Lightweight and easy to handle Efficient for low-risk, high-volume shipping Double Wall Gaylord Containers Construction: Double wall Gaylord containers feature two layers of corrugated cardboard, providing increased strength and durability compared to single wall options. Applications: Double wall containers are ideal for heavier or more delicate items that require extra protection. Common uses include: Metal parts, automotive components, or hardware Products requiring additional cushioning and support Moderate to long-distance shipping with multiple handling points Benefits: Enhanced strength and durability for heavier loads Better protection against impact and compression Suitable for stacking and efficient space utilization Triple Wall Gaylord Containers Construction: Triple wall Gaylord containers are constructed with three layers of corrugated cardboard, offering maximum strength and resistance to external pressures. Applications: These containers are best suited for the heaviest and most fragile items, providing superior protection during transit and storage. They are often used for: Heavy industrial components or machinery parts Fragile items like glassware or electronics Export shipping, where containers face prolonged handling and rough conditions Benefits: Maximum protection for heavy and fragile goods Optimal for international shipping and storage in harsh environments High resistance to punctures, compression, and impact Choosing the Right Gaylord Container Selecting the appropriate Gaylord container depends on several factors: Weight of Contents: Heavier items require double or triple wall containers for adequate support. Fragility: Fragile products benefit from the added protection of multiple wall layers. Distance and Handling: Longer shipping distances and frequent handling call for stronger container options. Budget Considerations: Single wall containers offer cost savings for less demanding applications, while double and triple wall containers are investments in product safety. Customization and Additional Features Gaylord containers can be customized to meet specific needs, including: Printing and branding for enhanced visibility Coating for moisture resistance Lids and liners for additional protection Dividers and inserts for organized storage Conclusion Gaylord containers are essential for industries requiring efficient and secure bulk packaging solutions. By understanding the differences between single, double, and triple wall options, businesses can choose the right container to protect their products, optimize shipping efficiency, and reduce costs. Whether you need basic packaging for lightweight items or robust protection for heavy machinery, Gaylord containers offer a versatile and reliable solution for all your bulk packaging needs. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Gaylord Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Selecting the right packaging supplier can be a daunting task, especially for newcomers in the market. The challenge often lies in balancing cost, value, product selection, order minimums, and design capabilities. While manufacturers offer direct access to production, they typically lack flexibility in product variety and additional services. On the other hand, distributors provide more options and flexibility but may lack direct control over production specifics. This is where hybrid packaging suppliers come into play, offering the best of both worlds. Understanding the Options: Manufacturer vs. Distributor vs. Hybrid Packaging Manufacturer Manufacturers are the primary source for packages, offering a direct line to the production process without a middleman. This direct relationship can lead to a more streamlined process and potentially lower costs. However, manufacturers often specialize in specific types of packaging and may not offer the breadth of services or customization that some businesses require. Advantages Streamlined production process In-house structural design team In-house product and material sampling Potentially lower costs due to direct sourcing. Specialized production capabilities. Disadvantages • Only offers 1 or a few products• Has specific order minimums (can be high or can be low)• Lack of flexibility in combining designs, materials, and other products (inserts, graphics, print options, finishes, and more)• No inventory management or just in time delivery (JIT)• No graphic design capabilities.• Global sourcing: cannot offer prices offered overseas Traditional Packaging Distributor Distributors act as intermediaries who source from various manufacturers, providing a broader range of products and greater flexibility. They can cater to clients who need diverse materials and design options under one roof, often with lower minimums than direct manufacturers. Advantages • Wide product selection• Flexible quantity minimums• Product, material, and design combination• Flexibility of machine capabilities (size, print, speed, and more)• JIT/Inventory Management Services Disadvantages • No in-house graphic design team• No in-house product and material sampling• Does not globally source • No project management from concept to completion The Hybrid Packaging Supplier Advantage Hybrid packaging suppliers combine the strengths of both manufacturers and distributors. They maintain control over the manufacturing process while offering the flexibility and variety typically associated with distributors. This model allows for a more tailored approach to packaging solutions, addressing specific needs without the typical trade-offs associated with other supply routes. Benefits of Choosing a Hybrid Supplier: Comprehensive Solutions: Hybrid suppliers manage the entire process from design through production, ensuring that all aspects of packaging are harmonized. Customization and Flexibility: They offer the customization capabilities of manufacturers with the product variety and flexibility of distributors. Cost-Effectiveness: By managing both production and supply, hybrid suppliers can optimize costs across the supply chain, potentially offering more competitive pricing. Reduced Lead Times: Integrating services under one roof can reduce the time from design to delivery. Quality Control: With direct involvement in manufacturing and design, hybrid suppliers can ensure higher standards of quality control. Ideal for Complex Projects Hybrid suppliers are particularly beneficial for clients with complex packaging needs. They are equipped to handle intricate designs that require a blend of different materials and technologies. Additionally, they can provide valuable input during the design phase to ensure that the packaging is not only visually appealing but also functional and compliant with any necessary regulations. Conclusion For businesses looking to streamline their packaging procurement process without sacrificing quality or flexibility, hybrid packaging suppliers represent an optimal choice. They eliminate the inefficiencies commonly encountered when dealing with separate manufacturers and distributors, providing a seamless, cost-effective, and highly adaptable packaging solution. In today’s market, where efficiency and adaptability are paramount, partnering with a hybrid packaging supplier can give businesses a significant competitive edge. By offering tailored solutions that meet specific packaging needs, hybrid suppliers ensure that their clients can focus on their core products without worrying about the complexities of the packaging process. If you are interested in working with a hybrid packaging supplier, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

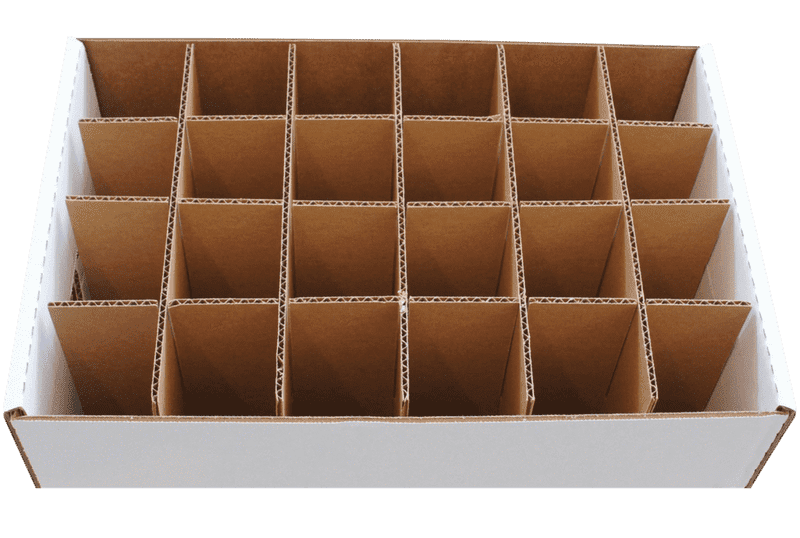

Corrugated partition inserts are an innovative packaging solution that can significantly enhance the functionality and efficiency of boxes. These inserts are made from corrugated cardboard, a versatile and durable material widely used in the packaging industry. By incorporating partition inserts, boxes can be transformed into organized compartments, providing protection, support, and separation for the packaged items. In this blog, we will explore the various benefits and applications of corrugated partition inserts, as well as their contribution to sustainable packaging solutions. Benefits of Corrugated Partition Inserts Protection and Stability Corrugated partition inserts offer excellent protection for delicate or fragile items during transit. The inserts can be designed to fit snugly inside the box, creating individual compartments that prevent the packaged items from shifting or colliding with each other. This added stability minimizes the risk of damage and ensures that products arrive at their destination in optimal condition. Improved Organization and Presentation With corrugated partition inserts, boxes can be organized and segmented into multiple compartments, allowing for better item separation and organization. This is particularly beneficial for industries such as cosmetics, electronics, and food, where products need to be individually stored or displayed. The inserts also contribute to a visually appealing presentation, creating an attractive and professional appearance for the packaged items. Enhanced Efficiency in Handling and Storage Partition inserts streamline the handling and storage process by simplifying the identification and retrieval of specific items. By providing separate compartments for each product, inserts eliminate the need for time-consuming searching or sorting through a box full of items. This increased efficiency can greatly benefit distribution centers, warehouses, and retail operations. Customizability and Versatility Corrugated partition inserts can be customized to fit the specific dimensions and requirements of various products. Manufacturers can design inserts with different cell sizes and configurations, allowing for optimal placement and protection of items with different shapes, sizes, and fragility levels. This versatility makes partition inserts suitable for a wide range of industries and product types. Applications of Corrugated Partition Inserts Electronics and Technology: The electronics industry often deals with delicate components that require individual protection. Corrugated partition inserts can safeguard circuit boards, computer chips, and other electronic parts from damage during shipping. The inserts ensure that each component remains secure and isolated, reducing the risk of static discharge and other potential hazards. Pharmaceutical and Healthcare: In the pharmaceutical and healthcare sectors, the integrity and safety of products are paramount. Partition inserts can be utilized to separate and protect vials, syringes, medicine bottles, and other medical supplies. These inserts help prevent contamination, breakage, and the mixing of different substances, ensuring the quality and efficacy of pharmaceutical products. Food and Beverage: Corrugated partition inserts find applications in the food and beverage industry, particularly for the packaging of fragile or delicate food items. Inserts can keep items like glass bottles, jars, or delicate products secure and separate from one another, minimizing the chance of breakage or spoilage. Additionally, partitioned compartments can be used to package multiple items together, allowing for easy assembly of gift sets or sampler packs. Sustainability and Corrugated Partition Inserts Corrugated partition inserts contribute to sustainable packaging solutions in several ways: Recyclability Like corrugated cardboard boxes, partition inserts are recyclable and can be transformed into new paper products. By using recyclable materials, companies can reduce their environmental impact and support a circular economy. Reduced Material Consumption Partition inserts optimize the use of materials by providing individual compartments, eliminating the need for excessive cushioning or additional packaging. This reduces the overall material consumption and waste generation. Lightweight and Space-Efficient Corrugated cardboard partition inserts are lightweight, which helps reduce transportation costs and carbon emissions. Their space-efficient design allows for more products to be packed in a single shipment, maximizing the use of cargo space and minimizing the need for additional vehicles. Biodegradability Corrugated partition inserts are made from natural fibers, which means they are biodegradable. When disposed of properly, they break down naturally over time without releasing harmful pollutants into the environment. Renewable Material Source Corrugated cardboard is made from a renewable resource—trees. Responsible forestry practices ensure the sustainability of the raw materials used in the production of corrugated partition inserts, minimizing the impact on forests and promoting environmental stewardship. Summary: Corrugated Partition Inserts Corrugated partition inserts offer numerous benefits for packaging applications, ranging from enhanced protection and organization to improved efficiency and presentation. Their customizability and versatility make them suitable for a wide range of industries, including electronics, pharmaceuticals, and food and beverage. Moreover, these inserts contribute to sustainable packaging solutions by being recyclable, lightweight, space-efficient, biodegradable, and sourced from renewable materials. By incorporating corrugated partition inserts into their packaging designs, companies can enhance the functionality of their boxes while minimizing their environmental footprint. If you are interested in corrugated partitions or other types of inserts, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts