Home » RSC vs. Specialty Boxes

RSC vs. Specialty Boxes

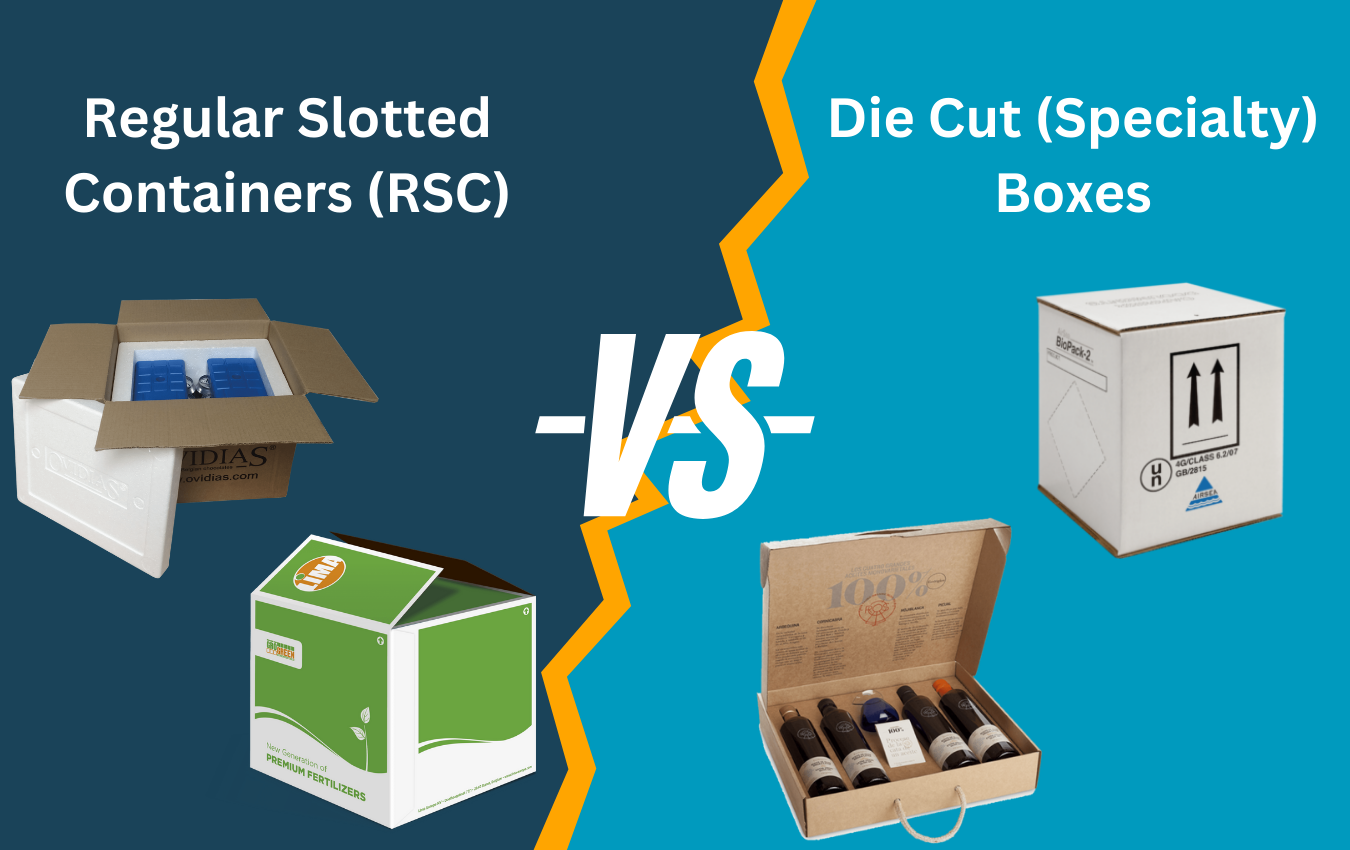

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer unique advantages for certain applications. Understanding when to stay with an RSC versus upgrading to a specialty style ensures buyers balance cost, performance, and presentation.

When RSC Is Best

- Bulk Shipping: Strong compression strength makes RSC ideal for palletized loads.

- Low Cost: Efficient to manufacture with minimal board waste.

- Versatility: Works across industries from industrial to retail.

- Automation-Ready: Standardized design runs smoothly on case erectors and palletizers.

When Specialty Boxes Are Better

Full Overlap (FOL)

- Flaps overlap fully, reinforcing the top and bottom.

- Better for heavy products or shipments that need extra stacking strength.

RETT Mailers

- Dust flaps and cherry locks eliminate tape, improving assembly speed.

- Ideal for e-commerce and branded unboxing experiences.

Die-Cut Boxes

- Custom shapes and closures for product-specific fit.

- Useful when presentation and consumer experience are top priorities.

Key Trade-Offs

Feature | RSC Box | Specialty Box Styles |

Assembly Speed | Slower (tape required) | Faster (die-cut, self-locking) |

Stacking Strength | High | Variable (higher in FOL, lower in mailers) |

Branding Potential | Basic | Premium (better graphics and unboxing) |

Flexibility | Universal | Application-specific |

Buyer Takeaway

- Stick with RSC when cost, strength, and scalability matter most.

- Upgrade to FOL for heavy-duty industrial shipments.

- Choose RETT or die-cut mailers for e-commerce and premium branding.

By evaluating your priorities — strength, speed or presentation — you can decide whether RSC remains the best fit or if specialty box styles deliver added value.

References

- Fibre Box Association. (2023). Corrugated Box Styles and Applications. https://www.fibrebox.org

- Association of Independent Corrugated Converters (AICC). (2024). Corrugated Design and Performance. https://www.aiccbox.org

- Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Home » RSC vs. Specialty Boxes

In the world of logistics and e-commerce, shipping is a critical aspect of business operations. Among the various packaging options, the Regular Slotted Container (RSC) box stands out as a versatile choice for shipping a wide range of products. To ensure your shipping endeavors with RSC boxes are both effective and efficient, it’s crucial to follow best practices and strategies. In this article, we’ll explore the key approaches to successfully ship RSC boxes. Choose the Right RSC Box Size Selecting the appropriate box size is essential when using RSC boxes for shipping. Oversized boxes waste space and may lead to higher shipping costs, while undersized boxes risk damaging your products. Therefore, it’s vital to measure your items carefully and opt for an RSC box that provides a snug fit with minimal extra space. Quality Matters Invest in high-quality RSC boxes. Boxes made from sturdy corrugated cardboard with durable seams and proper adhesive are crucial for protecting your products during transit. Quality boxes ensure that your goods reach their destination in optimal condition, without suffering damage due to external forces such as crushing or impacts. Proper Packing Material In addition to selecting the right RSC box, choosing the appropriate packing materials is equally important. Use cushioning materials like bubble wrap, packing peanuts, corrugated or foam inserts to safeguard your products from shocks and vibrations during shipping. Ensure there’s an adequate buffer between the product and the inner walls of the box. Seal Boxes Securely Properly sealing your RSC boxes is vital to prevent any unintended openings during shipping. Use high-quality packing tape to securely seal both the top and bottom flaps of the box. Ensure that the seams are tightly sealed, with no gaps or openings that could compromise the integrity of the box. Labeling and Documentation Clearly label each RSC box with essential information, including the recipient’s address, your return address, and any special handling instructions. Employ high-quality labels that won’t smudge or peel during transit. Additionally, don’t forget to include any required shipping documentation, such as packing slips, invoices, or customs forms, especially when shipping internationally. Weight Distribution Evenly distribute the weight of your products within the RSC box. Avoid placing heavy items on top of delicate ones. Utilize dividers or partitions if necessary to prevent items from shifting during transit. This practice helps maintain the structural integrity of the box and ensures that the products remain secure. Consider Environmental Impact Incorporate eco-friendly practices into your shipping process. Opt for recyclable and biodegradable packing materials whenever possible. Additionally, choose RSC boxes made from sustainable or recycled materials to reduce your environmental footprint. Shipping Carrier Selection Select a reputable shipping carrier that aligns with your business needs. Factors to consider include shipping speed, cost, reliability, and coverage. Negotiating shipping rates and exploring bulk shipping options can help reduce shipping costs. Track Shipments Utilize tracking services provided by shipping carriers. This enables you to monitor the progress of your shipments, provide customers with accurate delivery estimates, and promptly address any issues that may arise during transit. If you are interested in RSC Boxes, custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom RSC Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of sealing and closure not only ensures the safety and security of the contents but also can enhance ease of use, storage, and even branding. This blog post explores the different types of sealing and closure methods available for corrugated boxes, helping businesses choose the best option for their specific needs. Understanding the Importance of Proper Sealing and Closure Before delving into the types, it’s crucial to understand why sealing and closure matter. The right closure method can protect the contents from damage, theft, or contamination, while also providing an additional layer of branding through custom tapes or seals. Tape Closure One of the most common methods of sealing corrugated boxes is using tape. This method is versatile and cost-effective, suitable for a wide range of applications. Pressure-Sensitive Tape: Easy to apply, available in various widths and strengths, and ideal for lightweight to medium-weight boxes. Water-Activated Tape (WAT): Forms a strong bond with the corrugated box, offering superior security, and is excellent for heavier packages. Reinforced Water-Activated Tape: Best for heavy-duty applications, providing extra strength and security. Staple Closure Stapling is a traditional method of closing corrugated boxes, often used for heavy or industrial items. Manual Stapling: Suitable for small-scale operations or where additional security is needed. Pneumatic Stapling: Used in larger operations for efficiency and consistency in sealing. Glue Closure Adhesive or glue is another popular method, especially in automated packaging lines. Hot Melt Adhesive: Quick to apply and set, providing a strong and durable seal. Cold Glue Adhesive: Requires more time to set but offers a strong bond and is suitable for boxes that require refrigeration. Self-Locking Tabs and Slots For consumer-facing products, self-locking tabs and slots offer an appealing and tool-free option. Tab Lock: Simple to use, providing a secure closure without additional materials. Slot Lock: Offers added security as tabs lock into slots, making the box more tamper-resistant. Velcro or Hook-and-Loop Closures For reusable box designs, Velcro or hook-and-loop closures are ideal. Easy Open and Close: Allows for multiple uses, ideal for sample kits or storage boxes. Customizable: Can be designed in various shapes and sizes to suit specific packaging needs. Strapping or Banding Strapping or banding is used for heavy-duty applications or for bundling multiple boxes together. Metal Strapping: Offers the highest strength, ideal for heavy industrial goods. Polyester or Polypropylene Strapping: More flexible than metal, suitable for a wide range of applications. Sealing with Labels or Stickers Custom labels or stickers can double as a sealing method, particularly for light packages or as an additional security seal. Branding Opportunity: Custom labels provide a platform for branding and product information. Tamper-Evident Seals: Enhance security by indicating if the box has been opened. Conclusion The choice of sealing and closure method for corrugated boxes depends on several factors, including the weight and nature of the contents, the shipping and handling process, the need for security, and the desired customer experience. By selecting the appropriate sealing and closure method, businesses can ensure their products are well-protected and arrive at their destination in the best possible condition. Moreover, creative and practical sealing solutions can enhance brand recognition and provide an additional touchpoint for customer engagement. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

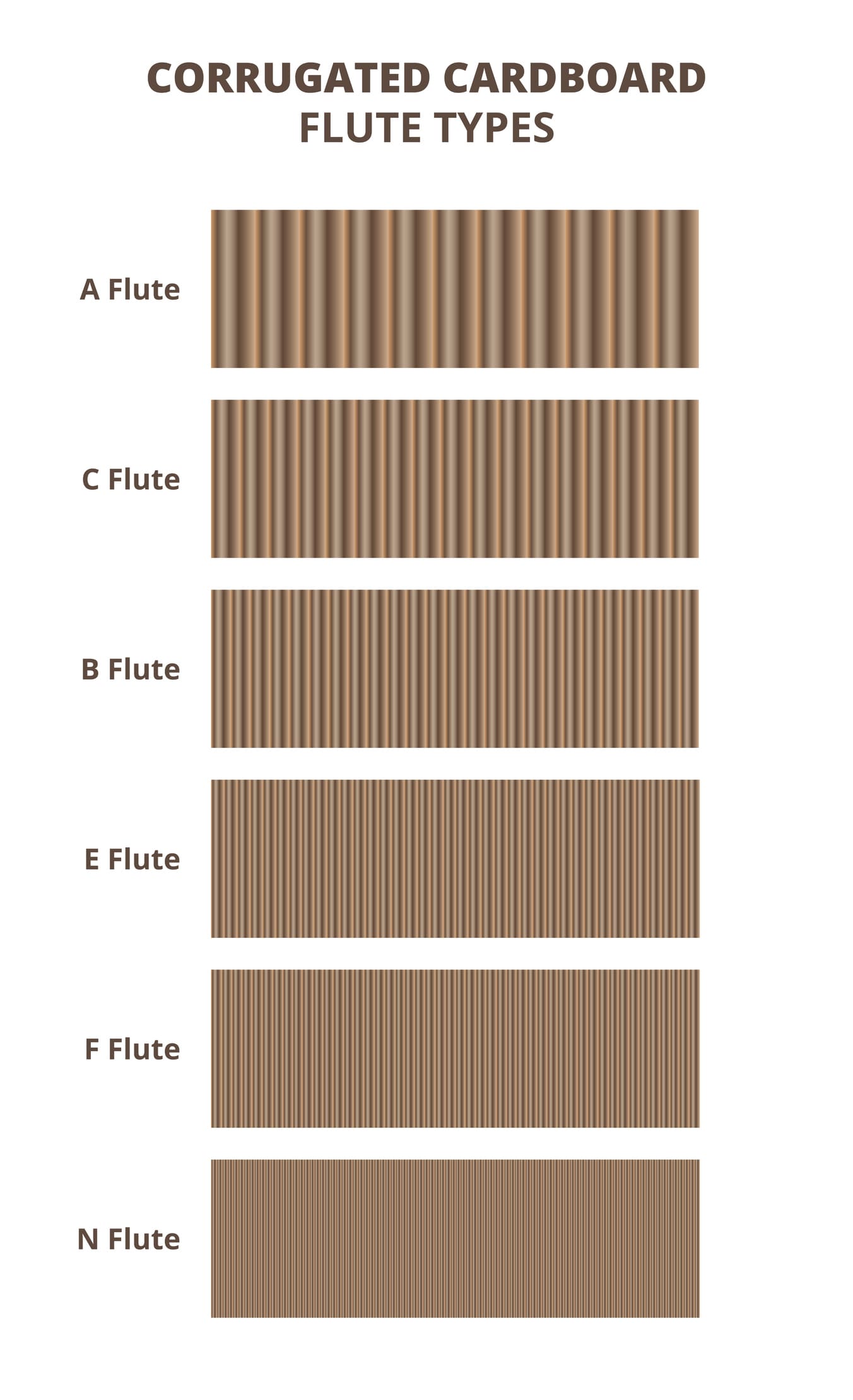

At a cursory glance, the humble cardboard box might seem like a straightforward item, yet it’s far more intricate and sophisticated than it initially appears. Deceptively simple, the construction of these boxes features numerous structural components that provide robustness, protection, and insulation, while offering an invaluable canvas for brand promotion. One of these often-overlooked components is the corrugated flute, a critical aspect of cardboard packaging that plays a vital role in the design and functionality of the box. This comprehensive guide will take a deep dive into corrugated flutes and their role in the packaging industry. Decoding Corrugated Flutes Corrugated flutes might escape the naked eye at first, but these wave-like patterns, nestled between the liner layers, form the very backbone of corrugated packaging. Integral to the composition of cardboard boxes, they turn these packages into sturdy containers, making them some of the most reliable methods for shipping and storage. Key Roles of Corrugated Flutes Corrugated flutes are much more than just layers of corrugated material. They play a central role in providing corrugated packaging with additional insulation and protection layers. Acting as the structural skeleton of the packaging, these flutes make the package crush-proof and puncture-proof, making it possible for boxes to bear the weight of heavy items without giving way or collapsing. To further understand the role of these flutes, let’s examine them in a typical shipping scenario. Packages often undergo considerable stress during transit, such as pressure from other boxes, jostling, or even puncture risks. The flutes within the corrugated box provide a cushioning effect that absorbs these shocks and helps protect the contents of the box. As a result, whether you’re shipping delicate glassware or weighty books, you can be confident that your items are secure within their corrugated packaging. A Detailed Look at the Five Types of Corrugated Flutes Not all corrugated flutes are created equal. The packaging industry employs five primary types of flutes, each serving specific needs and offering different benefits. Let’s explore these types in more detail: A Flutes With a thickness of approximately 5 millimeters or ¼ inch, the A flute is the thickest type available. Around 36 of these flutes can be found within a single linear foot of packaging, resulting in a highly robust structure for heavier items and excellent cushioning for delicate contents. A flute’s larger size provides optimal strength and compression properties, making it an excellent choice for products that require more support or have a higher risk of breakage. It’s no surprise then that A flutes are often used in packaging electronics, appliances, glass items, and other similar products. B Flutes The B flute, about 3.2 millimeters or ⅛ inch thick, falls into the mid-range category. With about 49 flutes per linear foot, it offers considerable crush and puncture resistance. B flutes provide an excellent surface for printing words, graphics, and logos directly onto the corrugated cardboard. Thanks to its combination of stiffness and compactness, the B flute is commonly used in retail packaging for items like canned goods. It is also commonly used in stand-up displays and for smaller boxes requiring a more refined print. Die cut boxes, generally use B – flute, as relatively small flute thickness helps when there a several scores and folds. C Flutes Being the second-thickest, C flutes measure around 3.2 millimeters or 11/64 inches in thickness, and about 41 flutes fit within a single linear foot. These flutes are ideal for shipping boxes due to their excellent resistance to crushing and compression. A C flute’s excellent stacking strength and printing capabilities make it a popular choice for transporting heavier products. Whether you’re moving a kitchen appliance or a batch of fresh produce, C flutes offer the durability and support needed. C- flute is the most popular thickness for general shipping boxes. E Flutes Second in thinness, E flutes are approximately 1.6 millimeters or 1/16 inch thick. As many as 90 flutes fit within a single linear foot, resulting in a lightweight but strong structure. The thinness of E flutes makes them an excellent choice for reducing storage space and costs. Because of its thinness and excellent printing surface, E flutes are commonly used in packaging consumer goods, particularly those requiring a more sophisticated presentation, such as cosmetics and high-end electronics. F Flutes The thinnest of all, F flutes measure around 0.8 millimeters or 1/32 inch in thickness. About 128 flutes can be found within a single linear foot, making them ideal for creating stiff packaging for specific consumer goods. Due to their thinness and smooth printing surface, F flutes are often used in retail packaging for luxury goods and other high-end items. Going Beyond Flutes: Board Types, Box Styles, and Printing Methods Understanding the world of corrugated packaging goes beyond flutes. There are several other critical considerations, such as board type, box style, and printing type. Each of these factors plays a vital role in determining the best packaging solution for specific products and brands. Board Type Corrugated packaging materials consist of a combination of flutes and liners, and this combination can vary depending on the packaging’s intended use. Let’s look at the four primary types of corrugated board: Single-face: As the name suggests, a single-face board consists of one layer of fluting and one liner layer. Although it’s not as durable as other types, its cushioning properties make it ideal for additional inner packaging components. Single-wall: This is the most commonly used board type, comprising one layer of fluting sandwiched between two liners. It offers sufficient insulation and protection, making it a popular choice for shipping cartons. Double-wall: Essentially two boxes in one, a double-wall board has three liner layers surrounding two layers of fluting. This super-durable board type is excellent for packaging heavy industrial items. Triple-wall: The most durable board type available, a triple-wall board has four liner layers and three fluting layers. It’s like having three boxes in one, which makes it ideal for robust applications such as extremely heavy metal pieces, equipment and chemical