Home » How Much Does Custom Packaging Really Cost?

How Much Does Custom Packaging Really Cost?

Custom packaging isn’t just an expense—it’s an investment that plays a pivotal role in brand identity, customer satisfaction, and even revenue growth. While many businesses shy away from custom packaging due to cost concerns, understanding its value and the factors influencing pricing can help you make informed decisions. In this blog, we’ll uncover the real cost of custom packaging, explore its benefits, and provide actionable tips to maximize your ROI.

Why Custom Packaging Matters

Custom packaging is more than a box or wrapper; it’s a brand statement and a customer experience enhancer.

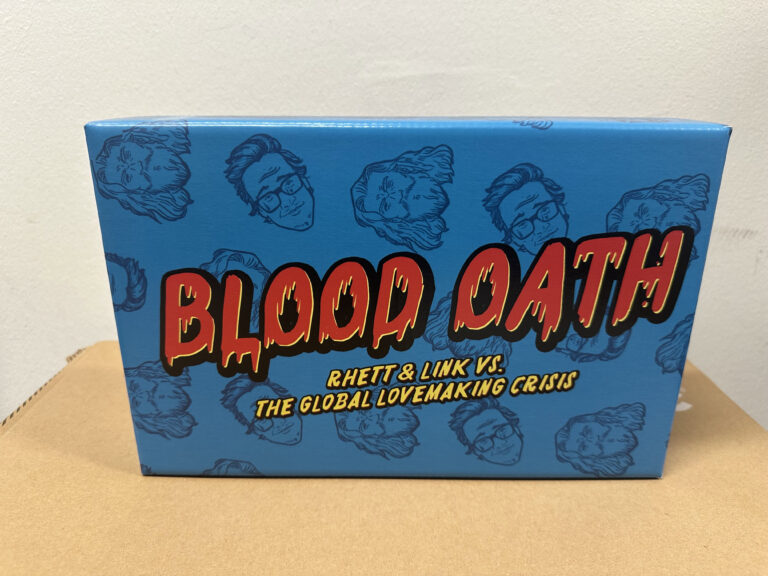

- Brand Identity: High-quality custom packaging reinforces your brand’s image, making your product instantly recognizable.

- Customer Experience: A memorable unboxing experience can create lasting customer loyalty and boost word-of-mouth marketing.

- Perceived Value: Premium packaging elevates the perceived value of your product, making it stand out from competitors.

Key Factors Influencing Custom Packaging Costs

Material Choices

The type of material used significantly affects cost and functionality.

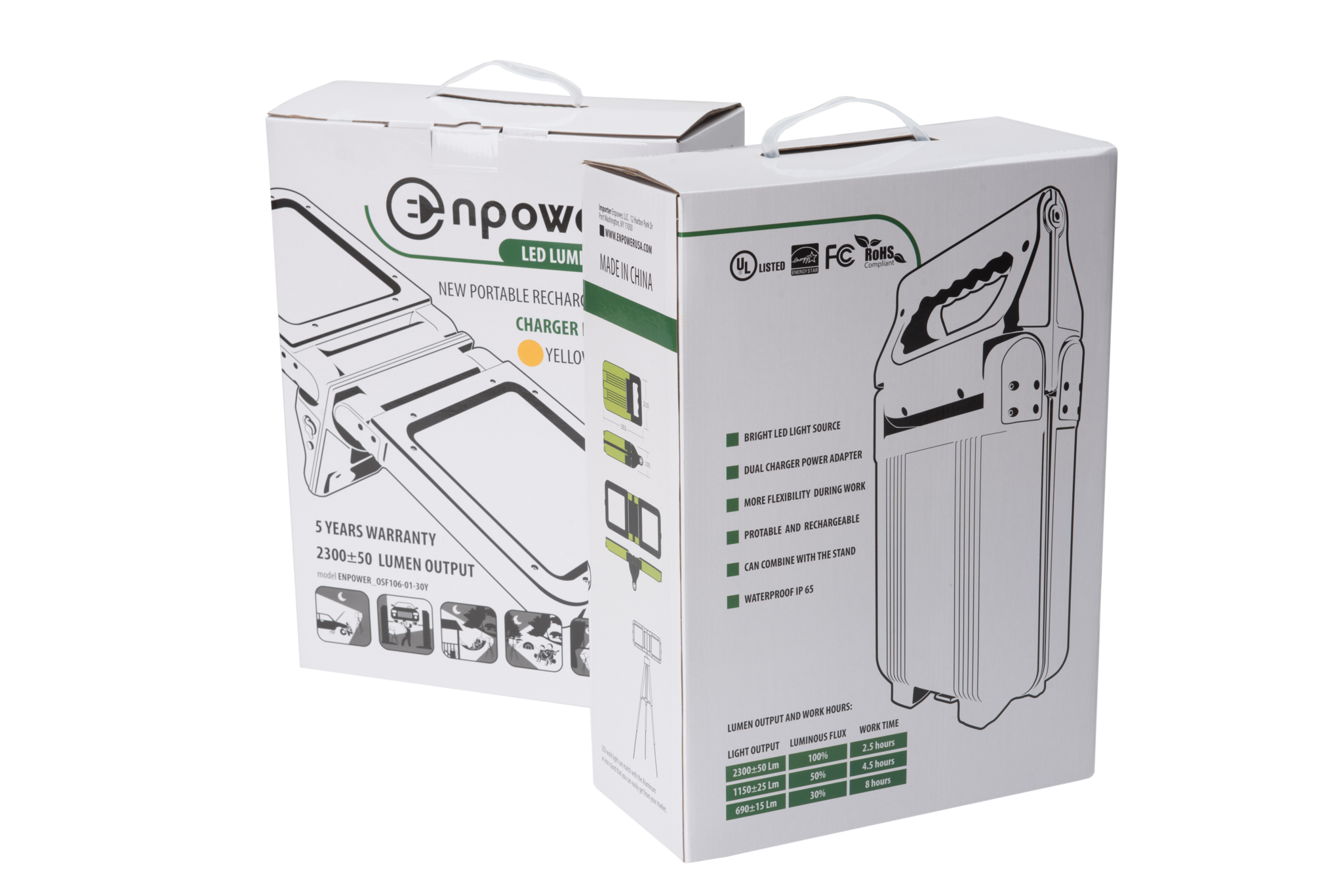

- Corrugated Boxes: Durable and cost-effective, ideal for shipping.

- Rigid Boxes: Luxurious but pricier, often used for high-end products.

- Eco-Friendly Options: Sustainable materials like kraft paper or biodegradable plastics, which appeal to eco-conscious consumers, can increase initial costs but offer long-term brand value.

Printing Techniques

- Digital Printing: Great for small orders; cost-effective but with limited precision.

- Offset Printing: Best for bulk orders; higher upfront costs but offers superior quality.

- Special Effects: Add-ons like embossing, foil stamping, or spot UV can enhance your design but also increase expenses.

Design Complexity

Intricate designs, custom shapes, and multi-component packaging raise production costs. Partnering with experienced designers can optimize the balance between creativity and cost.

Order Quantity

Bulk ordering reduces the per-unit cost due to economies of scale. Smaller orders may result in higher per-unit pricing.

Features For Common Packaging Types

Packaging Type | Key Features | |

Corrugated Boxes | Durable, recyclable, cost-effective. | |

Rigid Boxes | Luxurious feel, used for premium products. | |

Folding Cartons | Lightweight, customizable for retail. | |

Custom Mailer Boxes | Branding-focused, ideal for e-commerce. | |

Eco-Friendly Options | Sustainable, aligns with green initiatives. | |

How to Optimize Custom Packaging Costs

- Prioritize Materials Wisely

Choose materials that balance quality and cost. For example, opt for kraft paper for eco-friendly yet affordable packaging or corrugated boxes for high durability. - Leverage Bulk Orders

Order in bulk to take advantage of volume discounts. This strategy significantly reduces per-unit costs. - Simplify Design

A clean, minimalist design can be cost-effective and still make a bold statement. Complex designs often require more resources and time to produce. - Use Technology for Efficiency

Automation and advanced design software can streamline the production process, saving time and reducing errors.

Enhancing the Unboxing Experience on a Budget

You don’t need to overspend to impress your customers. Here’s how:

- Add personalized notes or custom stickers.

- Use branded tissue paper to add elegance without breaking the bank.

- Include QR codes linking to exclusive content or promotions.

FAQs About Custom Packaging Costs

How much does custom packaging design cost?

Design services typically range from $300 to $5,000, depending on the complexity and expertise involved.

What percentage of my product price should packaging cost?

Aim to allocate 8-10% of your product’s retail price to packaging costs.

Is custom packaging worth the investment?

Yes. Custom packaging enhances brand recognition, improves customer satisfaction, and can even justify premium pricing for your products.

Conclusion

Custom packaging is an essential tool for businesses looking to elevate their brand and enhance customer loyalty. By understanding the factors that influence cost and employing smart strategies to optimize expenses, you can create packaging that delivers both aesthetic and functional value without overextending your budget.

Ready to take your packaging to the next level? Partner with us to create customized solutions tailored to your brand and budget. Contact us today!

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » How Much Does Custom Packaging Really Cost?