Home » Recycling and Upcycling Corrugated Boxes

Recycling and Upcycling Corrugated Boxes

When you unwrap that eagerly awaited online order, or when the supermarket shipments arrive, corrugated boxes are almost always involved. With the increase in e-commerce and global shipments, the use of these boxes has surged. The question then arises: what do we do with all these boxes? The answer lies in the twin practices of recycling and upcycling. Let’s delve deep into the world of corrugated boxes, examining their environmental impact and how we can give them a second (or third) life.

The Environmental Impact of Corrugated Boxes

The Production Cost: The production of corrugated boxes requires vast amounts of energy and water. Trees are felled, processed, and transformed into paper pulp, which then becomes the corrugated cardboard we’re familiar with. While it’s true that many companies have started sourcing wood from sustainable forests, the process still consumes valuable resources.

Landfills: When discarded improperly, these boxes contribute to the already mounting waste in landfills. Although corrugated cardboard decomposes faster than plastics, it still takes between 3 to 8 months for it to fully break down. This decomposition can produce methane, a greenhouse gas 25 times more potent than carbon dioxide.

Carbon Footprint: From the transport of raw materials to the box’s final delivery, the entire lifecycle of a corrugated box adds to the carbon footprint. This doesn’t even account for the transportation of discarded boxes to landfills.

Recycling Corrugated Boxes

Recycling is the process of converting waste materials back into new products to prevent waste of potentially useful materials.

The Recycling Process: Once the boxes reach the recycling facility, they’re sorted, cleaned, and broken down into paper pulp again. This pulp is then used to create new cardboard or paper products.

The Benefits:

- Resource Conservation: Recycling corrugated boxes means fewer trees are cut down to produce new boxes.

- Energy Saving: Producing items from recycled materials consumes less energy compared to starting from scratch.

- Reduced Pollution: Fewer raw materials being processed means reduced air and water pollution.

Upcycling Corrugated Boxes

Upcycling, in contrast to recycling, involves creatively repurposing or redesigning waste materials into products of better quality or for better environmental value.

Creative Uses for Old Boxes:

- Storage Bins: Decorate and reinforce old boxes to create stylish storage solutions for your home.

- Wall Art: Cut out patterns or shapes from boxes, paint them, and fix them onto walls for an eco-friendly décor solution.

- Garden Solutions: Use flattened cardboard as a weed barrier in gardens. It’s biodegradable and effective.

- Kids’ Playhouse: Combine several boxes to create playhouses, castles, or forts for kids. They can even join in, painting and decorating.

- Pet Toys: Shape the cardboard into toys or scratch pads for pets. Cats, for instance, love corrugated cardboard scratchers.

- Gift Tags: Cut out small pieces, paint or decorate them, and use them as tags for gifts.

- Organizers: Craft compartmentalized trays or organizers for drawers or desks.

In conclusion, while corrugated boxes do pose an environmental challenge, through conscious efforts in recycling and upcycling, we can mitigate their impact. The journey of a box doesn’t have to end once its primary purpose is fulfilled. With a touch of creativity and environmental awareness, we can ensure that the story of every box is both inspiring and green.

If you are interested in corrugated boxes, then partner with Brown Packaging today to get started.

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance eco-friendly materials, cost, and compliance to build programs that are both effective and future-ready. What Buyers Need to Know About Sustainable Packaging Regulatory pressure: Governments are enforcing stricter rules on recyclability and plastic use. Retail mandates: FSC certification and recyclable packaging are becoming standard requirements. Consumer expectations: Customers increasingly choose brands with visible sustainability commitments. Sustainable Material Options Recycled corrugated: High recycled content while maintaining compression strength. Compostable films: Suitable for select food and retail applications. Molded pulp inserts: Replace foam or plastic for protective packaging. Water-based coatings: Enhance moisture resistance without harmful chemicals. Balancing Cost and Performance Right-size packaging: Reduces material waste and shipping costs. Hybrid solutions: Combine eco-materials with corrugated for balance. Life cycle analysis: Evaluate true environmental impact, not just marketing claims. How to Evaluate Sustainable Suppliers Verify FSC, SPC, or ISO certifications. Request testing data for durability and recyclability. Audit supply chains for consistency and transparency. Ensure claims meet local and international compliance standards. Packaging Solutions with Brown Packaging Brown Packaging helps buyers implement sustainable packaging programs that balance cost, performance, and compliance. From recycled corrugated to eco-friendly coatings and inserts, we deliver solutions that meet 2026 sustainability goals. Contact us to explore sustainable packaging options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Sustainability Trends and Buyer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026. What Is Single-Material Packaging? Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure. Advantages: Easier to recycle and dispose. Lower material costs in many cases. Streamlined sourcing and inventory. Supports sustainability messaging. Disadvantages: Limited barrier protection. Less customization for fragile or complex products. May require added thickness for strength, increasing weight. What Is Multi-Material Packaging? Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes. Advantages: Greater protection against moisture, oxygen, and impact. Allows for premium finishes and enhanced graphics. Ideal for fragile or high-value products. Customizable for unique supply chain conditions. Disadvantages: More difficult to recycle due to material separation. Higher cost and longer lead times. Complex sourcing and inventory management. When to Use Each Approach Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs. Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection. Balancing Performance and Sustainability Buyers must weigh performance needs against eco goals: Use recyclable coatings to extend single-material performance. Choose hybrid designs that separate easily for recycling. Apply multi-material solutions only where risk of damage outweighs cost. Packaging Solutions with Brown Packaging Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

One of the biggest challenges in sustainable packaging is balancing environmental responsibility with product protection. Buyers often worry that switching to eco-friendly materials means sacrificing durability or driving up costs. In 2026, new material technologies allow brands to meet sustainability goals without compromising strength or supply chain performance. Why Protection Still Matters Damaged products create more waste than packaging ever could. Returns increase logistics costs and carbon emissions. Retailers and e-commerce platforms expect packaging to deliver both sustainability and reliability. Eco-Friendly Material Options Recycled corrugated: Maintains stacking strength while reducing virgin fiber use. Molded pulp inserts: Cushion fragile items while replacing plastic foam. Water-based barrier coatings: Add moisture resistance without plastic films. Compostable films: Ideal for short shelf-life or single-use applications. Paper-based mailers: Replace poly mailers for e-commerce shipments. How to Balance Eco Goals and Protection Use right-sizing to reduce material volume while improving fit. Apply hybrid solutions (corrugated + pulp) for high-value goods. Conduct ISTA testing to validate protective performance. Match material choice to product fragility and supply chain conditions. Examples in Action Electronics: Molded pulp trays replacing EPS foam. Food and beverage: FSC-certified corrugated with recyclable coatings. Retail e-commerce: Recycled paper mailers protecting apparel. Packaging Solutions with Brown Packaging Brown Packaging develops eco-friendly solutions that protect products while meeting sustainability requirements. From recycled corrugated to innovative coatings, our team ensures you never trade protection for environmental impact. Contact us to explore eco-material options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Eco-Friendly Packaging Materials and Case Studies. Retrieved from https://sustainablepackaging.orgASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Recycling and Upcycling Corrugated Boxes

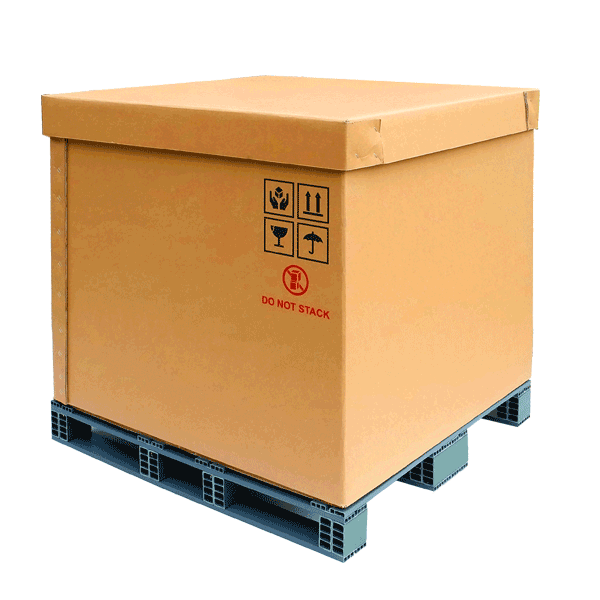

In the world of shipping and storage, the term “Gaylord box” often comes up, especially in industries that deal with bulk materials and goods. But what exactly is a Gaylord box, and why is it such a prominent player in logistics? In this comprehensive guide, we’ll dive into the world of Gaylord boxes, exploring their definition, common applications, advantages, and considerations for integrating them into your supply chain. Defining the Gaylord Box: More Than Just a Name A Gaylord box, often referred to simply as a Gaylord or Gaylord container, is a large, industrial-sized container designed for storing, transporting, and shipping bulk materials. These boxes are typically made from corrugated cardboard, plastic, or metal and come in a variety of sizes, ranging from around 2 feet to over 6 feet in height. The term “Gaylord” was originally a trademarked brand name that has become synonymous with this type of container. Common Applications of Gaylord Boxes: Versatility Unveiled Gaylord boxes find their application across a wide range of industries, each benefiting from their versatility and capacity. Some common sectors where Gaylord boxes are extensively used include: Manufacturing and Distribution: In manufacturing facilities and distribution centers, Gaylord boxes are utilized to efficiently transport raw materials, components, and finished products within the premises or to customers. Agriculture and Produce: For farms and agricultural operations, Gaylord boxes prove invaluable for packing and transporting fruits, vegetables, grains, and other harvested produce. Recycling and Waste Management: In recycling centers, Gaylord boxes become collection points for recyclable materials such as paper, plastic, and metal, streamlining the recycling process. Retail: In the retail sector, Gaylord boxes are employed to consolidate and transport goods from distribution centers to retail stores or directly to fulfillment houses. Automotive Industry: From auto parts to components, Gaylord boxes play a significant role in the storage and transportation of various automotive materials. Textile and Apparel: In the textile and apparel industry, Gaylord boxes provide a solution for packing and transporting fabrics, clothing, and other textiles. Construction and Building Materials: For the construction industry, Gaylord boxes are used to transport and store construction materials like tiles, bricks, and aggregates. Advantages of Gaylord Boxes: Unveiling the Benefits The popularity of Gaylord boxes can be attributed to several key advantages they offer: Bulk Handling: Gaylord boxes are designed for bulk storage and transport, making them an efficient choice for handling large quantities of materials. Stackability: The sturdy construction of Gaylord boxes allows for safe stacking, optimizing storage space in warehouses and trucks. Cost-Effective: Using Gaylord boxes for bulk shipping can often be more cost-effective than using individual smaller containers, reducing packaging and transportation expenses. Eco-Friendly Options: Many Gaylord boxes are made from recyclable materials, aligning with sustainability goals and reducing environmental impact. Durability: With their robust construction, Gaylord boxes are built to withstand the rigors of transportation and storage, protecting the contents from damage. Customizability: Gaylord boxes can often be customized with features such as flaps, access doors, and liners to suit specific needs. Considerations for Integrating Gaylord Boxes: Tailoring to Your Needs When considering the integration of Gaylord boxes into your operations, it’s important to take the following factors into account: Material Type: Choose the right material (cardboard, plastic, or metal) based on the type of materials you’ll be storing or transporting and the durability required. Size and Capacity: Select the appropriate size and capacity of Gaylord box that aligns with your specific needs and available storage or shipping space. Usage Environment: Consider the environment in which the Gaylord boxes will be used—whether it’s indoors, outdoors, or in temperature-sensitive conditions. Customization Needs: Evaluate whether you require any customization features, such as access doors, flaps, or liners, to enhance the functionality of the box. Sustainability Goals: If sustainability is a priority for your organization, opt for Gaylord boxes made from recyclable or eco-friendly materials. If you are interested in stock or custom gaylord boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce Design Display Flexible Packaging Foam Packaging Printing Protection Retail Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Gaylord Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of sealing and closure not only ensures the safety and security of the contents but also can enhance ease of use, storage, and even branding. This blog post explores the different types of sealing and closure methods available for corrugated boxes, helping businesses choose the best option for their specific needs. Understanding the Importance of Proper Sealing and Closure Before delving into the types, it’s crucial to understand why sealing and closure matter. The right closure method can protect the contents from damage, theft, or contamination, while also providing an additional layer of branding through custom tapes or seals. Tape Closure One of the most common methods of sealing corrugated boxes is using tape. This method is versatile and cost-effective, suitable for a wide range of applications. Pressure-Sensitive Tape: Easy to apply, available in various widths and strengths, and ideal for lightweight to medium-weight boxes. Water-Activated Tape (WAT): Forms a strong bond with the corrugated box, offering superior security, and is excellent for heavier packages. Reinforced Water-Activated Tape: Best for heavy-duty applications, providing extra strength and security. Staple Closure Stapling is a traditional method of closing corrugated boxes, often used for heavy or industrial items. Manual Stapling: Suitable for small-scale operations or where additional security is needed. Pneumatic Stapling: Used in larger operations for efficiency and consistency in sealing. Glue Closure Adhesive or glue is another popular method, especially in automated packaging lines. Hot Melt Adhesive: Quick to apply and set, providing a strong and durable seal. Cold Glue Adhesive: Requires more time to set but offers a strong bond and is suitable for boxes that require refrigeration. Self-Locking Tabs and Slots For consumer-facing products, self-locking tabs and slots offer an appealing and tool-free option. Tab Lock: Simple to use, providing a secure closure without additional materials. Slot Lock: Offers added security as tabs lock into slots, making the box more tamper-resistant. Velcro or Hook-and-Loop Closures For reusable box designs, Velcro or hook-and-loop closures are ideal. Easy Open and Close: Allows for multiple uses, ideal for sample kits or storage boxes. Customizable: Can be designed in various shapes and sizes to suit specific packaging needs. Strapping or Banding Strapping or banding is used for heavy-duty applications or for bundling multiple boxes together. Metal Strapping: Offers the highest strength, ideal for heavy industrial goods. Polyester or Polypropylene Strapping: More flexible than metal, suitable for a wide range of applications. Sealing with Labels or Stickers Custom labels or stickers can double as a sealing method, particularly for light packages or as an additional security seal. Branding Opportunity: Custom labels provide a platform for branding and product information. Tamper-Evident Seals: Enhance security by indicating if the box has been opened. Conclusion The choice of sealing and closure method for corrugated boxes depends on several factors, including the weight and nature of the contents, the shipping and handling process, the need for security, and the desired customer experience. By selecting the appropriate sealing and closure method, businesses can ensure their products are well-protected and arrive at their destination in the best possible condition. Moreover, creative and practical sealing solutions can enhance brand recognition and provide an additional touchpoint for customer engagement. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to packaging fragile or valuable items, ensuring their safe transportation is crucial. One effective way to protect these items during shipping or storage is by using edge protectors. Edge protectors are versatile packaging materials designed to safeguard the edges of products and prevent damage caused by impact, compression, or rough handling. While standard edge protectors are readily available, customizing them to suit your specific packaging needs can provide added protection and peace of mind. In this step-by-step guide, we will walk you through the process of customizing edge protectors for your unique requirements. Step 1: Assess Your Packaging Requirements Before customizing edge protectors, it’s essential to assess your packaging requirements thoroughly. Consider the size, shape, and fragility of the items you are packaging. Identify potential vulnerabilities, such as sharp corners or delicate surfaces that require extra protection. Additionally, determine the transportation or storage conditions your packages will be subjected to. By understanding your specific needs, you can tailor your edge protectors accordingly. Step 2: Select the Appropriate Edge Protector Material Edge protectors are available in various materials, each offering distinct benefits. Common materials include cardboard, foam, plastic, and composite materials. Cardboard edge protectors are ideal for light to medium-duty applications, while foam edge protectors offer excellent cushioning and shock absorption. Plastic edge protectors are durable and water-resistant, making them suitable for heavy-duty applications. Composite edge protectors combine multiple materials for enhanced protection. Choose the material that best aligns with your requirements. Step 3: Measure and Cut Once you’ve determined the material, it’s time to measure and cut the edge protectors to the desired length. Measure the dimensions of your item’s edges and add a few extra inches for overlap. This overlap will ensure complete edge coverage and optimal protection. Use a ruler or measuring tape to achieve accurate measurements. Then, using a sharp utility knife or scissors, carefully cut the edge protectors along the measured lines, unless they are custom made to the exact size. Step 4: Shape the Edge Protectors Depending on your packaging needs, you may need to shape the edge protectors to fit specific corners or edges. For example, if your item has rounded edges, you can create a curved shape in the foam edge protectors to provide a snug fit. Use a utility knife or scissors to make precise cuts and adjustments, ensuring a tailored fit for maximum protection. Step 5: Add Reinforcements (Optional) For particularly fragile or heavy items, you may consider reinforcing the edge protectors for added strength. Reinforcements can be achieved by layering multiple edge protectors together or by attaching additional support materials, such as adhesive foam pads or corner guards. Reinforcing the edge protectors will help distribute the impact and protect your items from potential damage. Step 6: Secure the Edge Protectors After customizing the edge protectors to fit your specific packaging needs, it’s time to secure them in place. Depending on the material and design of the edge protectors, there are several options for attachment. Adhesive backing, double-sided tape, or straps can be used to secure the edge protectors to the edges or corners of your item. Ensure that the edge protectors are firmly and evenly attached, leaving no gaps or loose ends. Step 7: Test for Adequate Protection Before finalizing your customized edge protectors, perform a thorough testing process to ensure they provide adequate protection. Mimic the transportation or storage conditions your packages will undergo, subjecting them to simulated impacts or rough handling. Inspect the packaged item for any signs of vulnerability or damage. If needed, make further adjustments to the edge protectors to enhance their protective capabilities. Step 8: Regularly Evaluate and Improve Packaging needs and requirements may evolve over time, so it’s crucial to regularly evaluate and improve your customized edge protectors. Stay updated with industry advancements and new packaging technologies that can enhance protection. Solicit feedback from your shipping or warehousing team and customers to identify areas for improvement. By continuously evaluating and refining your customized edge protectors, you can ensure the highest level of protection for your valuable items. If interested in custom edge protectors, then partner with Brown Packaging today. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Edge Protectors Facebook Twitter LinkedIn Pinterest Relevant Posts