Home » A Buyer’s Guide to Roll Stock

A Buyer’s Guide to Roll Stock

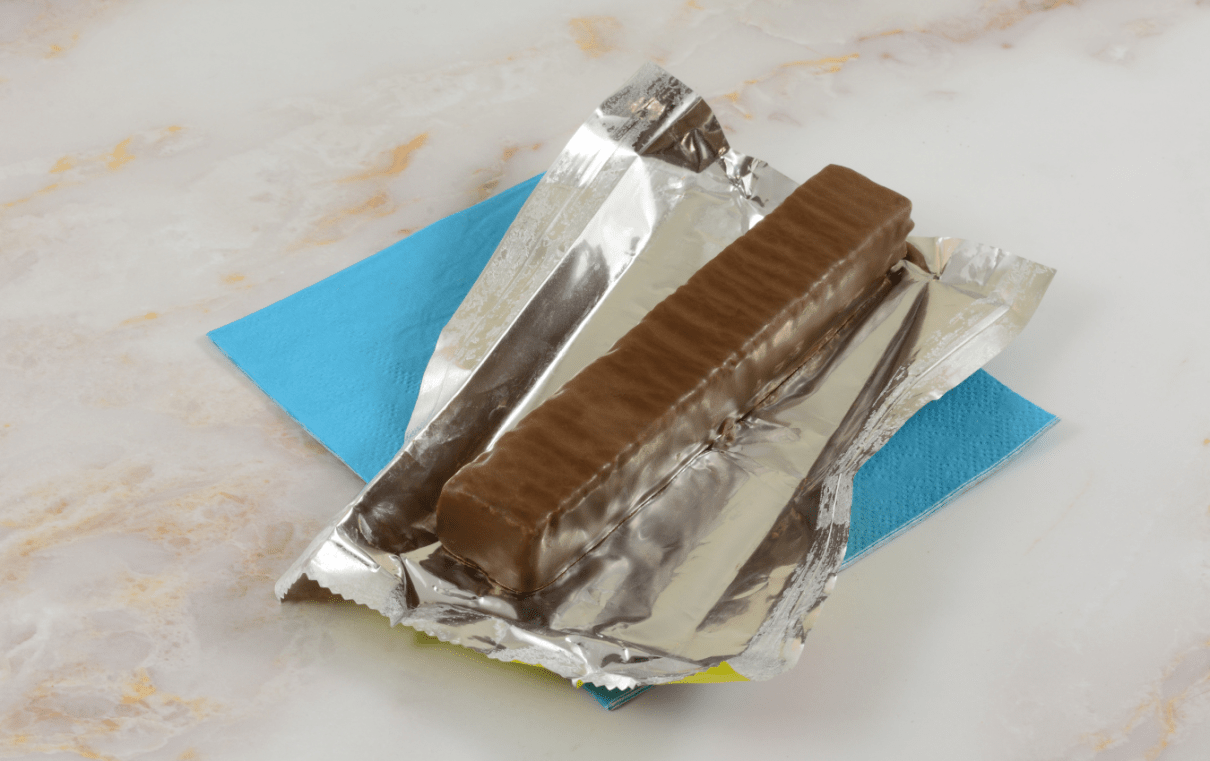

In the world of packaging, roll stock, also referred to as candy wrappers or snack wrappers, is a versatile and essential component. It refers to a continuous sheet of flexible material wound into a roll, used in various packaging applications. Roll stock materials come in a wide range of options, each designed to meet specific packaging requirements. Whether you are a seasoned packaging professional or a newcomer to the field, this buyer’s guide to roll stock will help you navigate the complexities of selecting the right material for your packaging needs.

Understand Your Packaging Requirements

Before diving into the specifics of roll stock materials, it’s crucial to understand your packaging requirements. Ask yourself the following questions:

- What type of product are you packaging?

- What are the dimensions and weight of your product?

- Is your product sensitive to environmental factors like moisture, oxygen, or light?

- What is the expected shelf life of your product?

- Do you require printing or branding on the packaging material?

- What is your budget for packaging materials?

By answering these questions, you’ll gain a clearer picture of your packaging needs and be better equipped to choose the right roll stock material.

Types of Roll Stock Materials

Roll stock materials come in various types, each offering unique characteristics and benefits. Here are some common roll stock materials:

Flexible Films:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polyester (PET)

- Nylon (PA)

Flexible films are suitable for a wide range of products, from food to electronics. They offer excellent barrier properties and are customizable for printing.

Foil Laminates:

- Aluminum foil laminated with various substrates

Foil laminates provide exceptional barrier properties against moisture, light, and oxygen. They are often used for perishable food items and pharmaceuticals.

Paper-Based Roll Stock:

- Kraft paper

- Coated paper

Paper-based roll stock is eco-friendly and ideal for products where a natural or rustic appearance is desired.

Specialty Films:

- Metallized films

- Biodegradable films

- Retort pouch films

Specialty films cater to unique packaging needs, such as high gloss, sustainability, and resistance to high-temperature processing.

Barrier Properties

Consider the barrier properties required for your product. For example, if you are packaging perishable goods, you’ll need materials with excellent moisture and oxygen barrier properties. Foil laminates and certain specialty films are often preferred for such applications.

Printing and Branding

If branding and aesthetics are crucial for your product, choose roll stock materials that offer excellent printability. Flexible films and paper-based materials are typically easier to print on, allowing for vibrant graphics and branding.

Environmental Impact

In today’s environmentally conscious world, it’s essential to consider the environmental impact of your packaging materials. Biodegradable films and sustainable materials are excellent choices for eco-friendly packaging.

Budget Constraints

Budget constraints are a significant factor in the decision-making process. While high-performance materials may offer superior properties, they can also be more expensive. Balance your budget with your packaging requirements to find the most cost-effective solution.

Regulatory Compliance

Ensure that your chosen roll stock material complies with relevant industry regulations and standards. This is particularly important for packaging in the food and pharmaceutical industries, where strict guidelines are in place.

Supplier Selection

Choose a reliable and reputable roll stock supplier. Look for a supplier with a proven track record of delivering high-quality materials on time and within budget.

If you are interested in packaging your products with roll stock, then partner with Brown Packaging today to get started.

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance eco-friendly materials, cost, and compliance to build programs that are both effective and future-ready. What Buyers Need to Know About Sustainable Packaging Regulatory pressure: Governments are enforcing stricter rules on recyclability and plastic use. Retail mandates: FSC certification and recyclable packaging are becoming standard requirements. Consumer expectations: Customers increasingly choose brands with visible sustainability commitments. Sustainable Material Options Recycled corrugated: High recycled content while maintaining compression strength. Compostable films: Suitable for select food and retail applications. Molded pulp inserts: Replace foam or plastic for protective packaging. Water-based coatings: Enhance moisture resistance without harmful chemicals. Balancing Cost and Performance Right-size packaging: Reduces material waste and shipping costs. Hybrid solutions: Combine eco-materials with corrugated for balance. Life cycle analysis: Evaluate true environmental impact, not just marketing claims. How to Evaluate Sustainable Suppliers Verify FSC, SPC, or ISO certifications. Request testing data for durability and recyclability. Audit supply chains for consistency and transparency. Ensure claims meet local and international compliance standards. Packaging Solutions with Brown Packaging Brown Packaging helps buyers implement sustainable packaging programs that balance cost, performance, and compliance. From recycled corrugated to eco-friendly coatings and inserts, we deliver solutions that meet 2026 sustainability goals. Contact us to explore sustainable packaging options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Sustainability Trends and Buyer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026. What Is Single-Material Packaging? Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure. Advantages: Easier to recycle and dispose. Lower material costs in many cases. Streamlined sourcing and inventory. Supports sustainability messaging. Disadvantages: Limited barrier protection. Less customization for fragile or complex products. May require added thickness for strength, increasing weight. What Is Multi-Material Packaging? Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes. Advantages: Greater protection against moisture, oxygen, and impact. Allows for premium finishes and enhanced graphics. Ideal for fragile or high-value products. Customizable for unique supply chain conditions. Disadvantages: More difficult to recycle due to material separation. Higher cost and longer lead times. Complex sourcing and inventory management. When to Use Each Approach Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs. Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection. Balancing Performance and Sustainability Buyers must weigh performance needs against eco goals: Use recyclable coatings to extend single-material performance. Choose hybrid designs that separate easily for recycling. Apply multi-material solutions only where risk of damage outweighs cost. Packaging Solutions with Brown Packaging Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

One of the biggest challenges in sustainable packaging is balancing environmental responsibility with product protection. Buyers often worry that switching to eco-friendly materials means sacrificing durability or driving up costs. In 2026, new material technologies allow brands to meet sustainability goals without compromising strength or supply chain performance. Why Protection Still Matters Damaged products create more waste than packaging ever could. Returns increase logistics costs and carbon emissions. Retailers and e-commerce platforms expect packaging to deliver both sustainability and reliability. Eco-Friendly Material Options Recycled corrugated: Maintains stacking strength while reducing virgin fiber use. Molded pulp inserts: Cushion fragile items while replacing plastic foam. Water-based barrier coatings: Add moisture resistance without plastic films. Compostable films: Ideal for short shelf-life or single-use applications. Paper-based mailers: Replace poly mailers for e-commerce shipments. How to Balance Eco Goals and Protection Use right-sizing to reduce material volume while improving fit. Apply hybrid solutions (corrugated + pulp) for high-value goods. Conduct ISTA testing to validate protective performance. Match material choice to product fragility and supply chain conditions. Examples in Action Electronics: Molded pulp trays replacing EPS foam. Food and beverage: FSC-certified corrugated with recyclable coatings. Retail e-commerce: Recycled paper mailers protecting apparel. Packaging Solutions with Brown Packaging Brown Packaging develops eco-friendly solutions that protect products while meeting sustainability requirements. From recycled corrugated to innovative coatings, our team ensures you never trade protection for environmental impact. Contact us to explore eco-material options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Eco-Friendly Packaging Materials and Case Studies. Retrieved from https://sustainablepackaging.orgASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In today’s competitive market, packaging affordability doesn’t start with cheaper materials — it starts with smarter design. Every score, fold, and insert decision affects not only how a box looks and feels, but how efficiently it’s made, shipped, and used. Structural engineering is the silent driver of cost efficiency — optimizing strength, space, and performance before the first sheet is ever printed. Why Structure Matters More Than You Think The most impactful cost savings in packaging rarely come from supplier discounts; they come from structural efficiency.A box that uses 10% less board but maintains the same compression strength directly reduces both material and freight cost. A redesigned insert that eliminates the need for secondary packaging saves time and labor at the line. Every cut line and fold path tells a story of cost, sustainability, and brand care — and when those align, affordability becomes part of your brand’s DNA. Designing for Efficiency, Not Excess In a market saturated with overbuilt packaging, engineering restraint is a competitive advantage. Structural teams now rely on 3D CAD modeling and virtual prototyping to simulate performance before production — identifying unnecessary material use and structural redundancies. Through precision die-line planning, engineers can improve sheet yield, reduce assembly time, and minimize void space — the dead air that drives up freight bills.It’s not about doing less; it’s about doing smarter. Balancing Protection and Presentation The temptation to “overprotect” products is common — especially in fragile or high-value goods. But protection doesn’t have to mean bulk. Strategic reinforcements, engineered fluting, and interlocking designs can maintain crush resistance and shock absorption while reducing total board weight. For e-commerce and shelf packaging alike, brands can achieve premium presentation with structural simplicity — a key to making packaging both sustainable and affordable. Prototyping to Prevent Waste Prototyping isn’t just for aesthetics — it’s a safeguard against costly production errors.With short-run sample testing and performance mockups, brands can evaluate fit, function, and protection early in development. Adjusting dimensions by fractions of an inch can save thousands in material waste and prevent rejected runs down the line. Smart packaging buyers now view prototyping not as an expense, but as a cost-control strategy that pays dividends in scale. How Structural Design Supports Brand and Budget Affordable design doesn’t mean compromising brand identity — it means integrating brand goals into structure. A well-engineered box reinforces trust, ensures product consistency, and communicates value through precision and fit. When structure, design, and production align, packaging stops being a cost and starts becoming a business asset. That’s where the real savings live — and where long-term brand equity begins. The Brown Packaging Difference At Brown Packaging, every packaging solution starts with structural intent — not guesswork.Our engineering and design teams collaborate to create packaging that performs across shipping, retail, and automation lines, balancing protection, brand visibility, and cost efficiency. We don’t cut corners; we cut waste.That’s how our clients achieve packaging that’s not just affordable — it’s engineered to perform. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. PMMI. (2024). Optimizing Structural Design for Packaging Efficiency. Packaging World. (2025). Engineering the Future of Cost-Effective Packaging. Smithers. (2025). Packaging Innovation and Material Efficiency Trends. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Every brand is feeling the squeeze — higher raw material costs, volatile freight rates, and a consumer base more price-conscious than ever. But cutting packaging budgets blindly can lead to damaged goods, compliance issues, and eroded brand value. Smart brands aren’t chasing cheaper boxes — they’re making smarter packaging decisions that balance performance, cost, and perception. The difference between saving money and losing value comes down to how you evaluate your packaging, not just what you pay for it. Beyond Unit Price: Understanding Total Packaging Cost A low unit price might look great on paper — until you factor in assembly time, damage rates, and freight efficiency. Smart packaging evaluation considers the total cost of ownership, including: Material yield (how efficiently sheets convert into boxes) Pallet and trailer utilization (freight optimization) Labor efficiency (ease of assembly or automation compatibility) Product protection (damage rates, replacements, and returns) When buyers assess all these metrics, the lowest-cost box often isn’t the best-value box. Material Selection That Saves in the Long Run Switching materials isn’t just about cutting cost — it’s about reducing waste and improving performance. For instance, moving from double-wall to a high-performance single-wall with better flute structure can cut weight and shipping cost without sacrificing protection. In folding cartons, substrate optimization — using a lighter caliper SBS or switching to coated recycled board — can yield savings that scale across production runs. And for rigid boxes, structural tweaks like thinner chipboard paired with strong wrap papers can preserve presentation while reducing material use. Every small change adds up when you scale across thousands of units. Design Efficiency: The Overlooked Cost Saver A smart structural design can eliminate cost before production even starts. Simplifying folds, reducing glue flaps, or reengineering inserts can cut assembly time and material waste. Modern packaging engineers use CAD-based dieline analysis to optimize layouts — ensuring maximum sheet yield and minimal offcut. For e-commerce and retail brands alike, right-sizing packaging improves shipping efficiency and reduces filler materials while maintaining the brand’s polished look. It’s not just design — it’s design that earns its keep Printing Smart: Matching the Process to the Purpose Not every job needs premium litho or complex spot varnishes. A good packaging partner matches print method to scale and brand intent: Flexo printing for high-volume, cost-efficient runs. Digital printing for short runs, personalization, and multi-SKU campaigns. Litho laminating for high-end visuals in rigid or premium retail displays. By choosing the right print method early, brands can avoid over-engineering — saving both time and money without compromising quality. Data-Driven Decisions: The New Standard for Packaging Buyers Leading companies now use data to guide packaging spend. Damage rate metrics, SKU-level freight analysis, and consumer perception studies all contribute to smarter choices. Smart buyers are no longer asking, “What’s the cheapest box?” They’re asking, “What’s the most efficient box that protects the product, ships well, and supports brand goals?” This mindset shift is what separates cost-cutting from cost control. The Brown Packaging Approach At Brown Packaging, we help brands make smarter packaging decisions by combining engineering analysis, supplier network leverage, and real-world testing. Our process aligns packaging performance with total cost goals — from box design to print selection and logistics. The result: stronger packaging, lower waste, and sustainable cost savings that scale with your business. Because in today’s market, smart packaging isn’t just a cost center — it’s a competitive advantage. References PMMI. (2025). Operational Cost Efficiency in Packaging and Logistics. McKinsey & Company. (2024). Total Cost of Ownership in Consumer Goods Packaging. Packaging World. (2025). Data-Driven Decisions in Packaging Sourcing. Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » A Buyer’s Guide to Roll Stock

The food industry has undergone a variety of changes over the years, with one of the most prominent shifts being in the area of packaging. In this pursuit of improvement and innovation, flexible packaging has come to the forefront. From the grocery store aisle to the restaurant kitchen, flexible packaging is becoming increasingly prevalent. But why is this the case? Below, we explore the key advantages of flexible packaging in the food industry. Enhanced Shelf Life and Food Safety One of the primary benefits of flexible packaging is the increased shelf life it offers for food products. The materials used in flexible packaging are designed to protect food from environmental factors such as moisture, light, and oxygen, all of which can speed up the spoilage process. By keeping these elements at bay, flexible packaging helps to preserve the freshness, taste, and nutritional value of food for longer periods, ultimately reducing food waste. Moreover, flexible packaging provides improved food safety. It creates a barrier against contaminants and bacteria, reducing the risk of foodborne diseases. Sustainability and Lower Environmental Impact Sustainability is a crucial consideration in the modern world, and flexible packaging shines in this aspect. This packaging method requires less energy to manufacture and transport due to its lightweight nature. Consequently, it contributes to a lower carbon footprint compared to more traditional forms of packaging. Additionally, flexible packaging utilizes less material overall, which means less waste is generated at the end of its life cycle. And while recycling capabilities for flexible packaging still have room for growth, strides are being made in this area, and many types of flexible packaging are already recyclable. Cost-Effectiveness From a financial perspective, flexible packaging can offer significant savings for food businesses. As previously mentioned, it’s lightweight, which reduces transportation costs. Additionally, because it’s efficient and compact, more units can be shipped or stored in a single space compared to rigid packaging, maximizing logistical efficiency. Flexible packaging also offers cost savings in terms of reduced food spoilage. By extending the shelf life of products, businesses can reduce the frequency of unsold products being thrown away, enhancing their bottom line. Consumer Convenience The ease and convenience of flexible packaging are hard to overstate. Features like resealability, microwavable pouches, and easy-open tear notches cater to the modern, on-the-go consumer who values time-saving options. These user-friendly features also add to the overall consumer experience, improving the perception of the brand and increasing the chances of repeat purchases. Innovative Branding and Marketing Opportunities Flexible packaging acts as a canvas for creative and eye-catching designs, offering ample branding and marketing opportunities. Unlike rigid packaging, flexible packaging allows for 360-degree product visibility and design, giving brands the ability to stand out on crowded supermarket shelves. The flexibility also allows for customization in packaging shape and size, providing further ways for a brand to differentiate its products. Conclusion: A Future-focused Packaging Solution In conclusion, the food industry’s adoption of flexible packaging is far from arbitrary. It provides a multitude of advantages, including enhanced food safety and shelf life, sustainability, cost-effectiveness, consumer convenience, and innovative branding opportunities. As the food industry continues to evolve and consumer demands shift, flexible packaging will likely become an even more prominent feature of our grocery aisles and kitchen cupboards. It’s not just a trend—it’s a future-focused solution for a more sustainable and efficient food industry. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Flexible packaging stands out in the packaging industry for its adaptability and efficiency. Utilizing materials that can flex and mold, this type of packaging adjusts its shape when filled or sealed, catering to a diverse range of products. The evolution of material technologies has not only made flexible packaging more cost-effective but also reduced material consumption during manufacturing, positioning it as a preferable alternative to traditional rigid and corrugated packaging solutions. Comprehensive Overview of Flexible Packaging Materials Used in Flexible Packaging The foundation of flexible packaging lies in its diverse material selection, each offering unique properties: Low Density Polyethylene (LDPE): Commonly used for its softness and flexibility, ideal for products requiring heat sealing. It’s resistant to various chemicals and is predominantly used in food packaging and consumer goods. High Density Polyethylene (HDPE): Known for its robustness and chemical resistance, making it suitable for household cleaning supplies, poly mailers, and items that encounter stress during shipping. Polypropylene (PP): With its high heat resistance, PP is perfect for packaging products that may be exposed to heat, such as microwaveable foods and certain consumer electronics. Polyethylene Terephthalate (PET): Offers excellent clarity and barrier properties against moisture and gases, widely used in the food and beverage industry. Polyvinyl Chloride (PVC): Chosen for its durability and resistance to environmental factors, PVC is used in non-food packaging such as shrink films and sturdy containers. Flexible Packaging Products and Their Applications Flexible packaging can be customized to suit a broad range of applications, offering unique solutions that are both protective and promotional: Pouches: Available in various styles such as stand-up, flat, and side gusset, pouches are popular for food products, cosmetics, and small consumer goods. Roll Stock: This material is used to create custom bags or pouches, tailored to specific product dimensions, commonly used for snacks, candies, and nutritional bars. Poly Bags: These versatile bags are suitable for a wide array of products, from apparel to food and electronics, featuring options like resealable closures and custom prints. Plastic and Bubble Mailers: Designed for shipping, these mailers are lightweight, durable, and can include bubble cushioning for added protection. Pouch Roll Stock Poly Mailer Benefits of Flexible Packaging The advantages of flexible packaging are numerous, making it a preferred choice for many businesses: Environmental Impact: Many materials used in flexible packaging are recyclable, and ongoing advancements are enhancing biodegradable and compostable options. Customization and Branding: Flexible packaging allows extensive customization in printing and design, enabling effective brand promotion and consumer engagement. Cost Efficiency: The lightweight nature of these materials reduces shipping costs and decreases the overall environmental footprint. Supply Chain Efficiency: Flexible packaging requires less storage space and can be transported more efficiently, allowing for more products per shipment compared to rigid packaging solutions. Pouch Roll Stock Poly Bag Conclusion: Flexible Packaging Explained: Flexible packaging offers a dynamic approach to packaging, combining innovative material use with functional design to meet a variety of industry needs. Whether for food, pharmaceuticals, or consumer goods, flexible packaging provides tailored solutions that enhance product protection, display, and sustainability. For businesses considering this packaging option, understanding the specific material properties and potential applications is crucial for making an informed decision. For further assistance and to explore flexible packaging solutions tailored to your needs, consider reaching out to packaging experts like Brown Packaging. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Flexible packaging is a dynamic and growing market that has revolutionized the packaging industry. From snack foods to pharmaceuticals, flexible packaging offers lightweight, cost-effective, and versatile solutions that cater to a wide range of products. With advancements in materials, printing, and technology, flexible packaging has become a popular choice for brands looking to differentiate themselves and meet changing consumer needs. In this blog, we will explore the top flexible packaging trends of 2023 that are driving sustainability and convenience. Quick Overview: 10 Flexible Packaging Trends of 2023 Sustainability Takes the Lead Digital Printing and Personalization Convenience is Key Smart Packaging The Rise of E-commerce Interactive Packaging Premiumization Transparency and Visibility Antimicrobial Packaging Resealable and Portion Control Packaging Sustainability Takes the Lead Consumers are increasingly concerned about the impact of packaging waste on the environment. As a result, sustainability has become a key driver in packaging innovation, and flexible packaging is no exception. Brands are embracing eco-friendly materials, such as plant-based and compostable plastics, to reduce their carbon footprint. Furthermore, lightweight and recyclable packaging is gaining popularity, as it reduces the use of materials and lowers transportation costs. Digital Printing and Personalization The rise of digital printing technology has enabled brands to personalize their packaging, creating a unique and memorable experience for customers. Flexible packaging allows for high-quality graphics and printing, enabling brands to showcase their products in a visually appealing way. This trend is expected to continue in 2023, with brands using digital printing to differentiate their products and attract consumers. Convenience is Key Consumers are increasingly busy and seeking products that fit their on-the-go lifestyles. Flexible packaging provides a convenient solution, allowing products to be easily transported and consumed. Packaging features such as resealable closures and easy-to-open seals are becoming standard, while innovative packaging designs that make products easier to use and consume are emerging. Smart Packaging The Internet of Things (IoT) has revolutionized many industries, and packaging is no exception. Smart packaging technology integrates sensors, NFC tags, and QR codes to provide information to consumers and enhance their experience. In 2023, we expect to see more brands adopting smart packaging technology to offer a range of benefits, such as improved product tracking, food safety, and consumer engagement. The Rise of E-commerce The pandemic has accelerated the shift towards e-commerce, with online shopping becoming the norm for many consumers. Flexible packaging is ideal for e-commerce, as it offers cost-effective and lightweight solutions that can be easily shipped. Brands are expected to continue investing in e-commerce packaging in 2023, with features such as tamper-evident seals and easy-open tear notches becoming essential. Interactive Packaging Interactive packaging takes personalization to the next level, offering a fun and engaging experience for customers. This type of packaging can include augmented reality, QR codes, or other interactive elements that allow customers to learn more about the product, access exclusive content, or play games. Premiumization As consumers become more discerning, premiumization has become a key trend in flexible packaging. High-quality materials, sophisticated design, and premium finishes are increasingly being used to create a premium look and feel for products, elevating the perceived value and enhancing the overall consumer experience. Transparency and Visibility Consumers are increasingly interested in the source, quality, and safety of the products they buy. Flexible packaging is ideal for showcasing product transparency and visibility, with clear windows or see-through packaging. This trend is expected to continue in 2023, with brands using transparent and visible packaging to build trust and convey product quality. Antimicrobial Packaging In the wake of the COVID-19 pandemic, antimicrobial packaging has emerged as a trend for 2023. Antimicrobial packaging contains agents that inhibit the growth of bacteria, viruses, and fungi, making it ideal for products that require high levels of hygiene and safety. Resealable and Portion Control Packaging Consumers are increasingly looking for portion control and convenience when it comes to packaging. Resealable packaging allows customers to consume products at their own pace, while portion control packaging ensures that products are used in the right quantities. These features are expected to continue to be popular in 2023, especially for products such as snacks and beverages. Conclusion: Flexible Packaging Trends For 2023 In conclusion, flexible packaging is a dynamic and evolving industry that is driven by innovation and sustainability. As we look ahead to 2023, we expect to see brands continue to prioritize eco-friendly materials and digital printing, while also focusing on convenience and smart packaging. With the rise of e-commerce and changing consumer needs, flexible packaging is set to play an increasingly important role in the packaging industry. If you are interested in flexible packaging for your products, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts