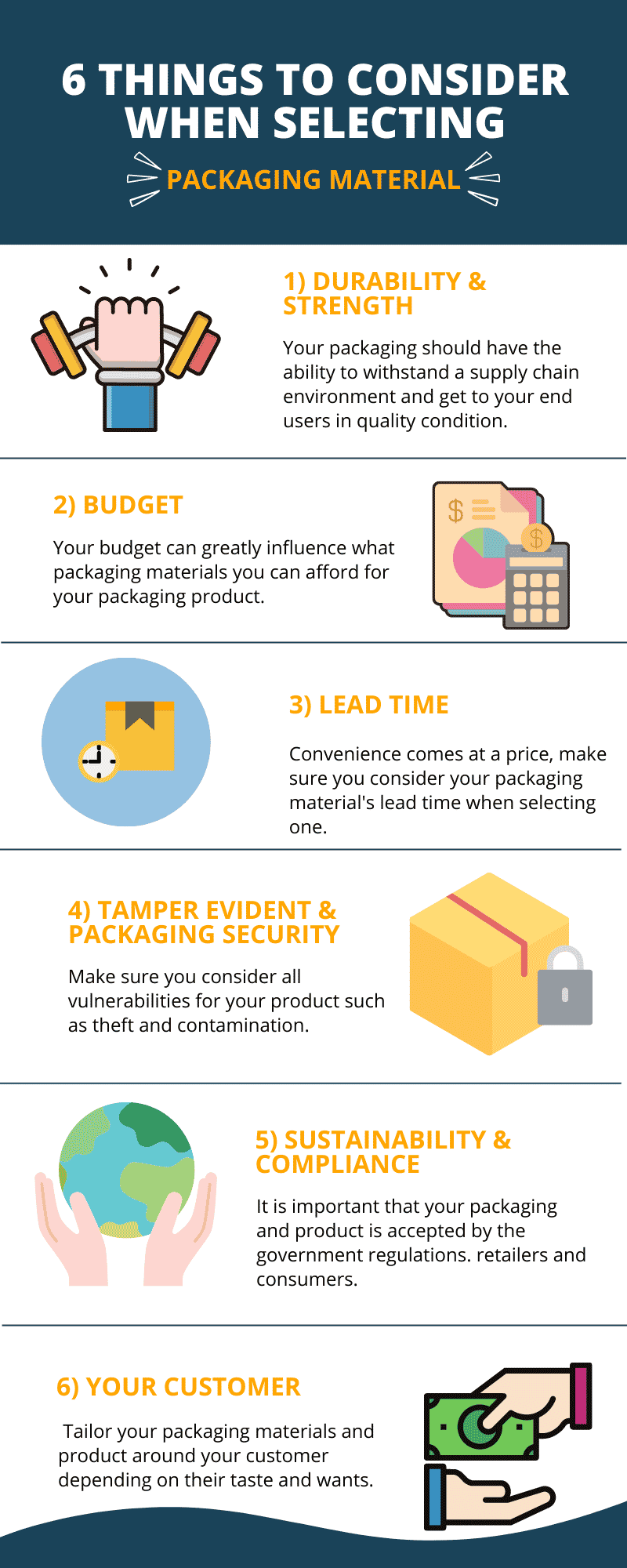

Home » 6 Things To Consider When Selecting Packaging Materials

6 Things To Consider When Selecting Packaging Materials

Selecting the right packaging materials is a critical decision for businesses, impacting everything from product protection and shelf life to brand perception and sustainability. With a variety of materials available, each offering different benefits and challenges, understanding what to consider when choosing packaging options can greatly influence your business outcomes. Here are six essential factors to evaluate when selecting packaging materials for your products.

Durability and Quality

The durability and quality of your packaging are paramount as they protect your product throughout the supply chain and influence customer perceptions of your brand.

Considerations for Durability and Quality:

- Product Requirements: Evaluate the size, shape, weight, and vulnerability of your product. Heavier and more fragile items might require sturdier materials like corrugated fiberboard or thick plastics, whereas lighter items may be sufficiently protected with lighter materials such as paperboard or thin plastic.

- Protection Needs: Determine the level of protection required against factors such as moisture, UV rays, and mechanical damage. This may influence the choice of material as well as the need for additional protective features like coatings or reinforcements.

Budget

Your budget will significantly influence the type of packaging materials you can afford. It’s crucial to balance cost with the quality and functionality needed to protect and sell your product effectively.

Budgetary Considerations:

- Material Costs: Compare the cost of various materials and consider their trade-offs in terms of durability and aesthetics. For example, while corrugated solutions might be more expensive than paperboard, they offer enhanced protection.

- Long-Term Savings: Consider investing in higher-quality materials that might reduce the need for replacements or returns due to damage, potentially saving money in the long run.

Lead Time

The time it takes to produce and deliver your packaging can impact your ability to meet market demands and maintain inventory levels.

Lead Time Factors:

- Production Schedules: Choose materials that align with your production schedules and inventory needs. High-demand periods may require materials with shorter lead times.

- Supplier Reliability: Ensure your supplier can consistently meet your lead time requirements to avoid disruptions in your supply chain.

Tamper Evident and Secure

Securing your products against tampering is crucial for maintaining customer trust and ensuring the integrity of your products upon delivery.

Security Features:

- Tamper-Evident Seals: Consider materials and designs that incorporate tamper-evident features such as seals, shrink wraps, or security tapes.

- Durability of Seals: Ensure that the materials selected are compatible with security features and will hold up under normal handling conditions.

Sustainability and Compliance

With increasing consumer and regulatory demands for environmental responsibility, selecting sustainable packaging materials is more important than ever.

Sustainable Packaging Choices:

- Recyclable Materials: Opt for materials that are easily recyclable within most municipal systems, such as certain plastics, paperboard, and corrugated fiberboard.

- Biodegradable Options: Consider biodegradable or compostable materials if they meet the protective requirements of your products.

Understanding Your Customer

Knowing your target market is essential in selecting the right packaging materials that resonate with your consumers’ values and expectations.

Customer-Centric Packaging:

- Market Preferences: Tailor your packaging materials to the preferences of your market. Luxury consumers may prefer high-end materials that reflect the quality of the product, whereas eco-conscious consumers may prioritize sustainable materials.

- User Convenience: Consider ease of use, such as easy-open features or resealable packages, which can enhance the customer experience and satisfaction.

Choosing the right packaging materials involves a careful balance of functional, aesthetic, and economic factors. By considering these six aspects, businesses can select materials that not only protect their products effectively but also align with brand values, meet consumer expectations, and stay within budget constraints. Partnering with an experienced packaging provider like Brown Packaging can help navigate these choices, ensuring you select the best materials for your products’ specific needs.

Contact Brown Packaging for expert guidance and to explore a wide range of packaging solutions tailored to your business requirements.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » 6 Things To Consider When Selecting Packaging Materials

Packaging is an essential element of product marketing. It not only protects the product but also plays a significant role in brand identity and consumer

A study published in September 2024 in Frontiers in Toxicology has identified 189 chemicals present in food packaging materials that are potential or confirmed mammary carcinogens,

The industrial sector depends heavily on efficient, scalable, and cost-effective packaging—whether it’s for machinery parts, building materials, electronics, or bulk components. But with ongoing tariff