Home » 5 Ways Custom Packaging Can Enhance Product Visibility and Sales

5 Ways Custom Packaging Can Enhance Product Visibility and Sales

Product visibility and sales are two most crucial factors that directly contribute to the success of any business. In the era of the highly competitive retail industry, businesses are always in search of innovative strategies that can enhance their product’s visibility and, consequently, sales. Among these strategies, custom packaging has emerged as an incredibly powerful tool. Not only does it make a product stand out, but it also serves as a silent salesperson, speaking volumes about the brand and its value proposition.

In this blog, we will explore five ways that custom packaging can enhance product visibility and ultimately boost your sales.

Differentiation and Brand Identity

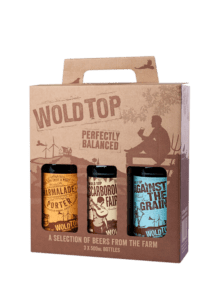

In a market where multiple brands sell similar products, differentiation is key. Custom packaging allows businesses to convey their unique identity and distinguish their products from the crowd. A well-designed package can reflect your brand’s personality and values, establishing an emotional connection with your target customers. For instance, eco-conscious brands may opt for sustainable packaging to resonate with like-minded consumers. This kind of clear, visual differentiation not only enhances visibility but also fosters brand loyalty, which can lead to increased sales.

Enhanced Shelf Impact

Shelf impact is a crucial factor that influences buying decisions at the point of purchase. Custom packaging, with its unique designs, shapes, and colors, can enhance the product’s appeal on the shelves. Customers’ eyes are naturally drawn to items that stand out, so designing a package that is visually arresting and clearly communicates the product’s benefits can significantly increase the likelihood of the product being noticed and picked up.

Unboxing Experience

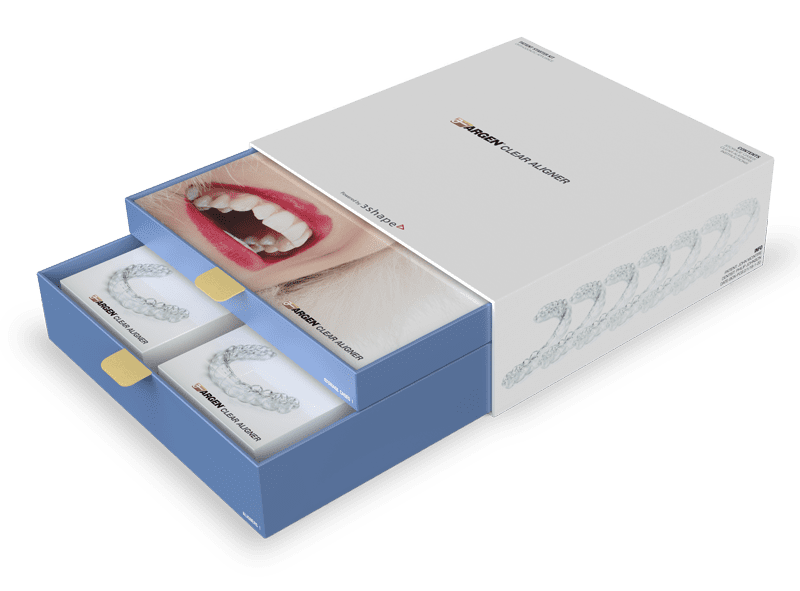

In the age of social media, the unboxing experience has become an integral part of the customer journey. A product packaged in a custom box provides a memorable unboxing experience that customers may share on social media platforms, thereby acting as free advertising and reaching a larger audience. This not only amplifies product visibility but also provides potential customers with a sneak peek into the product, thereby increasing their likelihood of making a purchase.

Imparting Value and Quality

Custom packaging can serve as an indicator of a product’s value and quality. High-quality, attractive packaging suggests that a lot of thought and care has gone into the product, implying that the product itself is of high quality. By investing in high-quality custom packaging, you communicate to customers that your product is worth their money, which can, in turn, drive sales.

Reinforcing Brand Message and Story

Every brand has a unique story and message. Custom packaging offers a valuable opportunity to reinforce this message and communicate your brand story directly to your customers. This can be done through creative use of design elements, color schemes, and even printed stories or messages on the packaging itself. By creating an emotional resonance with your brand, customers are more likely to remember your product and choose it over others.

In conclusion, custom packaging goes far beyond simply holding a product; it is a significant aspect of brand identity, product visibility, and customer engagement. It provides a unique opportunity for businesses to differentiate themselves, create a memorable unboxing experience, impart perceived value and quality, and reinforce their brand message. As such, businesses should see custom packaging not as an expense, but as a strategic investment that can significantly enhance product visibility and drive sales.

If you are interested in custom packaging solutions, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » 5 Ways Custom Packaging Can Enhance Product Visibility and Sales

Packaging is an essential aspect of any product, and it is vital for the success of small businesses. Effective packaging not only protects the product

With the rise in accidental medication ingestions by children each year, it has become increasingly important to implement child-resistant packaging. Among various packaging solutions, child-resistant

Whether you’re traveling with your bike, shipping it to a new location, or selling it, choosing the right bike shipping box is essential for safe