Home » 3 Tips to Selecting the Right Packaging Supplier

3 Tips to Selecting the Right Packaging Supplier

Finding the right packaging supplier for your business can be challenging, as there are many companies to choose from. Suppliers vary in quality of service and products in addition to lead time, expertise, cost, capabilities, and product selection. As a result, it is best to partner with a company that is the best fit for your project.

To select the right packaging supplier for your company, you are going to have to invest time in understanding your project needs, screening potential prospects, and determining which company you feel most comfortable working with.

To help guide you along the selection process, we have created 3 tips you should follow in selecting the right packaging provider.

Understand Your Packaging Project

The first thing you want to do before looking for a packaging supplier is to understand your project. What are your goals and what are you trying to achieve in addition to what product or products are you looking to package. Brainstorm with your team and do research on products like yours.

The better idea you have on your requirements can help you establish what you are looking for in a packaging supplier. To understand your project, you should at least know whether you need custom or stock packaging, the budget allocated for this project and have begun planning your logistics and warehousing for the final product packaging.

Determine Whether You Need Custom or Stock Packaging

Not all packaging is readily available on the shelf or even in the market. This is because a good portion of the packaging created is custom made, while the other is stock.

Stock packaging is readily available for purchase. It is much cheaper than custom, but is only available in limited sizes, usually the most common. Most types of packaging are available in stock such as corrugated boxes, pouches, tapes, labels and more. Stock products often appear plain without any finishes, graphics, or print.

Custom packaging is not readily available as it must be created through a process. Depending on the quantity custom products may be more expensive but are much more flexible in size, shape, features, and design. Many businesses utilize custom packaging to optimize their efficiency, produce sales and improve branding.

Try to determine whether you need custom or stock packaging. If you are still unsure about what type of packaging you will need, then speak to multiple packaging companies about your solutions.

Set A Packaging Budget

Unless you are experienced or a routine customer of a packaging supplier, you will not know the market cost for your type of project. This doesn’t mean you cannot set a budget now and change it later, but it can serve as a guideline to what you are looking to spend. When developing your project’s budget, you should consider as many factors as you possibly can such as the type of packaging, volume, and freight.

Your budget will dictate which packaging provider will work with you, as most suppliers tend to have order minimums to cover costs. If your budget is low, then the availability of packaging suppliers will be lower.

If you have a decent to large budget for your project, then you can pretty much work with any packaging supplier on the market that can accommodate your demand. Usually, these businesses are business to business (B2B) packaging providers. For custom projects, products not being readily available may limit your selection of suppliers as large orders can overwhelm production of smaller manufacturers. In addition, some manufacturers may not even have adequate machinery to produce your packaging, which can lead to high costs and longer lead times.

Set Project Deadlines

Some packaging projects are time sensitive. Maybe you need to refill your inventory, give a presentation with product samples or you just do not want to wait forever to get your product. As a result, you should always establish a deadline for your project and hold your packaging supplier accountable for meeting those deadlines.

Not every packaging provider has the same capabilities and resources to fulfill your orders within a desired timeline. You should keep this in mind when evaluating and comparing prospective packaging suppliers you want to work with.

Evaluate and Compare Prospective Packaging Suppliers

Packaging companies vary from one another by the services and products, quality and price, capabilities, experience, expertise, and other factors. To effectively know whether a packaging supplier is right for you, you must evaluate and compare them.

First you want to determine whether you need a manufacturer or a distributor. This will help narrow down which packaging providers you will consider and learn about. Ask questions to learn more about what a company can offer you. Take into consideration their location as it may affect logistic costs and lead time. Lastly, you want to look over any company reviews or testimonials to develop a reliable perspective on what to expect working with this supplier.

Determine Whether You Need a Manufacturer or Distributor

A packaging manufacturer and a distributor are two different types of suppliers. Choosing the correct one will help eliminate any confusion and streamline your packaging process without creating unnecessary delays and expenses. Before you select one, learn the differences between the two.

Manufacturers are limited to their machines, which only enables them to produce a very limited number of products. For example, if you were getting a corrugated box manufactured from them and need a foam insert, you will have to purchase the foam insert separately from another manufacturer. Manufacturers are also limited in print options and other custom design features, depending on their machinery.

A distributor partners with a network of manufacturers to produce packaging. Distributors offer much more flexibility than manufacturers by providing a wider range of products and options. A traditional distributor lacks in-house capabilities of structural design and prototyping, while a manufacturer can easily supply these.

Hybrid suppliers are a new and less common type of packaging supplier. These companies have the advantages of both providers, while limiting the disadvantages of both.

For more information comparing manufacturers, distributors and hybrid suppliers; read our blog “Why You Should Choose A Hybrid Packaging Supplier.”

The more you know about these different types of packaging suppliers, the better chances you have at selecting the right manufacturer, distributor, or hybrid supplier for your project needs.

Learn About Prospective Packaging Companies

You want to learn as much about the packaging companies you are considering for your project. The more you know the better you will know if they are a good fit or not. When you meet with or talk with a packaging specialist you want to ask questions, consider their location, and check their references (if applicable).

Ask Questions

Asking questions will help you determine how experienced and knowledgeable a company is at addressing your project, in addition to how attentive and interested they will be in your project. Here is a list of 10 essential questions you should ask your packaging supplier (read blog for detailed explanation):

- What packaging products do you offer?

- Do you offer any services?

- Are you a manufacturer or distributor?

- What is your expected lead time?

- Is there an order minimum?

- Can you supply me with samples, if needed?

- Can you meet retailer requirements?

- Do you have any recommendations or concerns for my project?

- How much does it cost for delivery?

- Are you experienced in projects like mine?

Consider Their Location

Location may be a deal breaker for some buyers. If you partner with a company that is not local, then all communication will have to be done remotely. For some projects, this may create an issue if you want to see past project physical examples and ideas.

It is important to mention that not all packaging is accepted in different parts of the world or the United States. As some countries ban or prevent the manufacturing of certain packaging materials such as expanded polystyrene, also known as Styrofoam. As a result, you may have to cover this with your prospective packaging supplier.

Longer distances usually translate to more expensive freight. It is important to compare costs with other suppliers when getting quotes from farther packaging companies.

Examine Reviews

A packaging company can make promises and guarantees to close a deal, however past customer reviews can paint a more accurate picture on what you will experience working with a company. Reviews can back the credibility of a packaging supplier’s wonderful services and product, or it can discredit them with unprofessionalism and poor communication.

Do your research on a packaging provider before you work with them. If they do not have reviews, ask to see project samples. Evaluate how the company presents themselves in person and online to evaluate their credibility.

Select The Company That Is The Best Fit

Ultimately, you want to select the company you feel the most comfortable with and who you feel can deliver you the most value. When selecting a packaging provider be sure to understand your project. This will help you carefully select the right suppliers that you will evaluate and compare their capabilities, services, and product options. Be sure to check company reviews and ask questions to learn more about a prospect’s credibility, reputation, experience and expertise.

Put your project in good hands and partner with Brown Packaging, we are a hybrid packaging supplier with over 30+ years of experience serving businesses of all industries throughout the United States and California. We are a one-stop shop for all your packaging needs with in-house capabilities, services, stock, and custom packaging. Contact us to get started on your next packaging project.

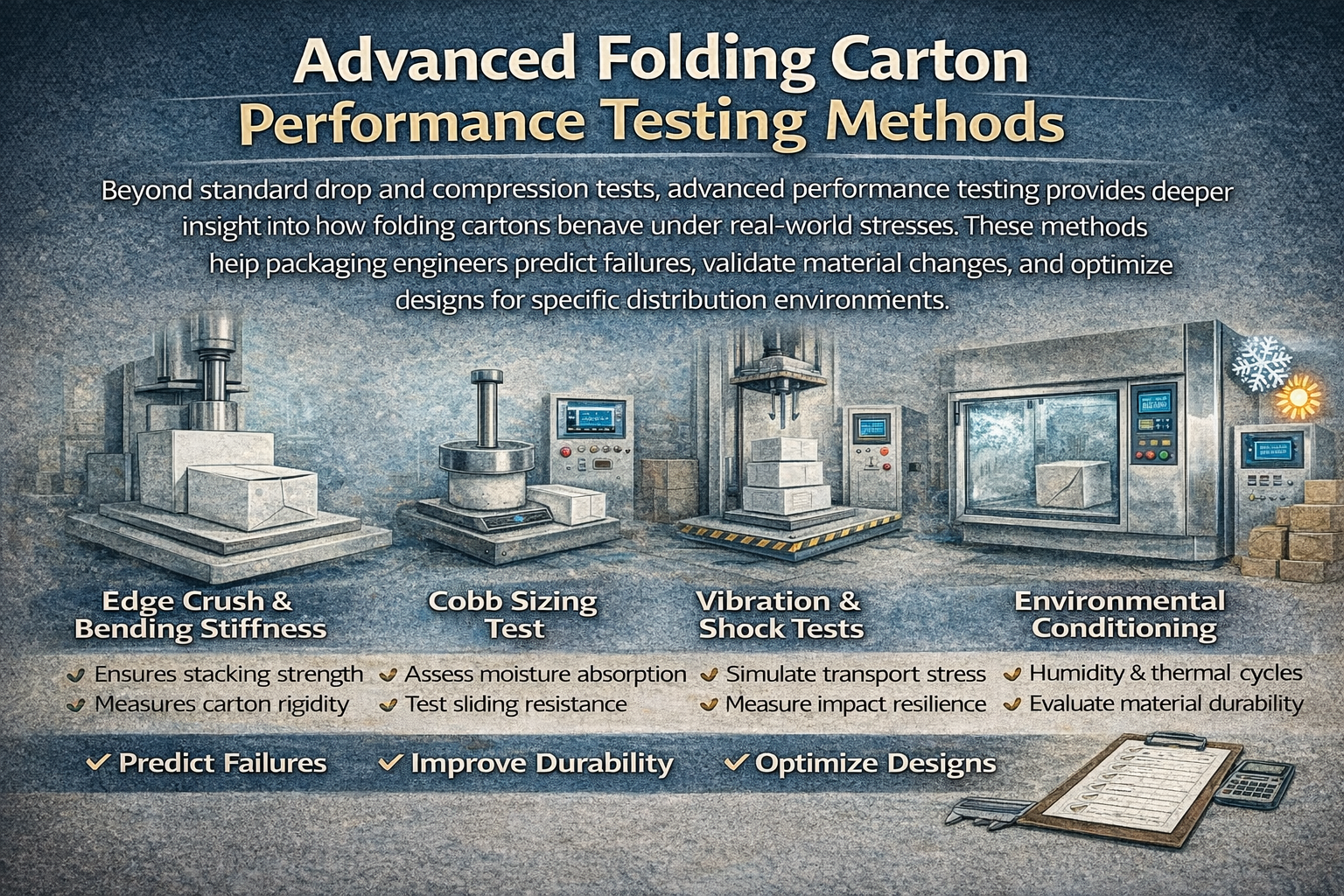

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers

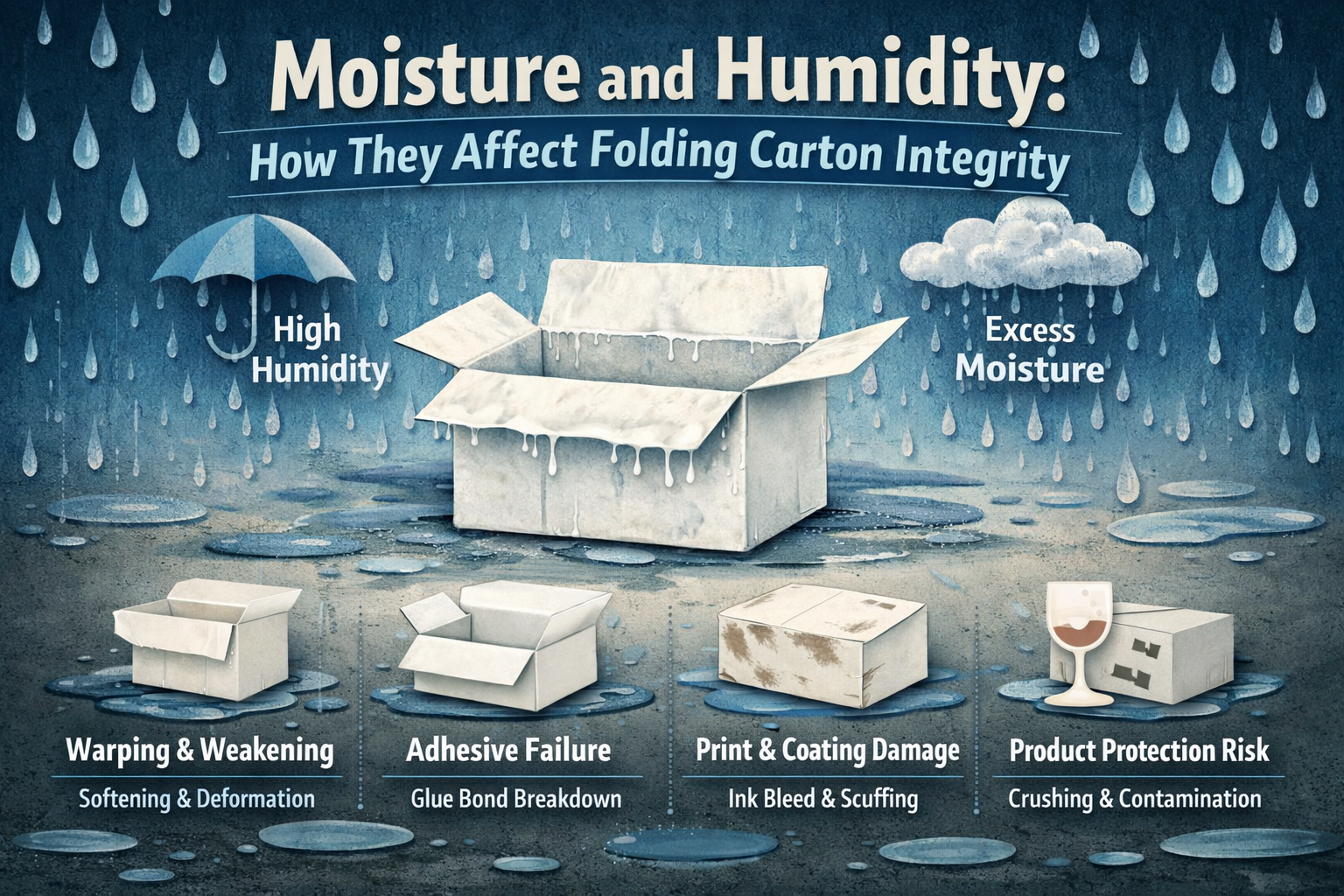

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » 3 Tips to Selecting the Right Packaging Supplier

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected