Home » 12 Print Tips for Corrugated Box Buyers

12 Print Tips for Corrugated Box Buyers

Corrugated boxes are essential to shipping, retail, and e-commerce—but when you introduce custom printing, the stakes (and the opportunities) rise. Print isn’t just about looks—it’s about communication, branding, compliance, and customer experience. Whether you’re designing a basic shipper or a bold, shelf-ready display, printing smart can save money and elevate your packaging.

Here are 12 essential print tips to help buyers make informed decisions when sourcing printed corrugated boxes.

Start With Purpose Before Design

Are you trying to impress in-store, create a branded unboxing experience, or simply add a logo to a shipper? Your goal will determine how much print you need—and which method is best.

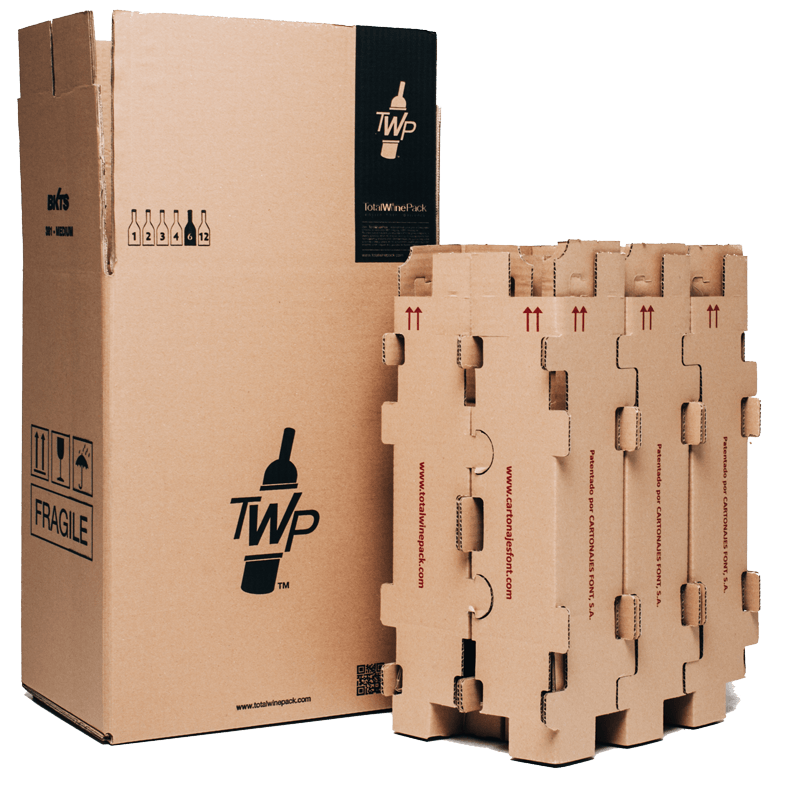

Know the Three Main Print Methods

- Flexographic (Flexo): Cost-effective for simple graphics and large runs

- Digital: Great for short runs, versioning, or quick turnarounds

- Litho (Litho-Label): High-end graphics mounted to the box for premium results

Choose based on your volume, detail level, and budget.

Understand Your Print Surface

Corrugated comes in kraft (brown) and white surfaces.

- White gives better color accuracy

- Kraft offers an organic, eco-conscious look

Your surface will affect how your design prints—especially with flexo.

Keep Artwork Simple for Flexo

Flexo printing uses plates and works best with limited colors, bold text, and clean logos. Avoid gradients, fine details, or small fonts unless you’re going digital or litho.

Use Vector Files and High-Res Assets

Always supply artwork in vector format (AI, EPS, or PDF) for scalability and sharp print. Images should be 300 DPI or higher. Low-res files can distort or blur during printing.

Design Around the Dieline

Your design should be laid out directly on the box dieline. This ensures correct placement of logos, cut lines, folds, and glue areas—so nothing important gets trimmed or hidden.

Limit Ink Coverage to Reduce Cost

Full-coverage ink areas (flood coats) require more material and setup. Consider printing only on key panels or using the box’s natural color to create contrast and cut costs.

Test Color on Corrugated First

Colors will appear differently on kraft vs. white corrugated and on different print methods. Always ask for a sample or press proof to verify color before production.

Use Pantone Colors (When Needed)

For brand consistency, especially with logos or specific brand colors, use Pantone Matching System (PMS) inks instead of CMYK—especially in flexo.

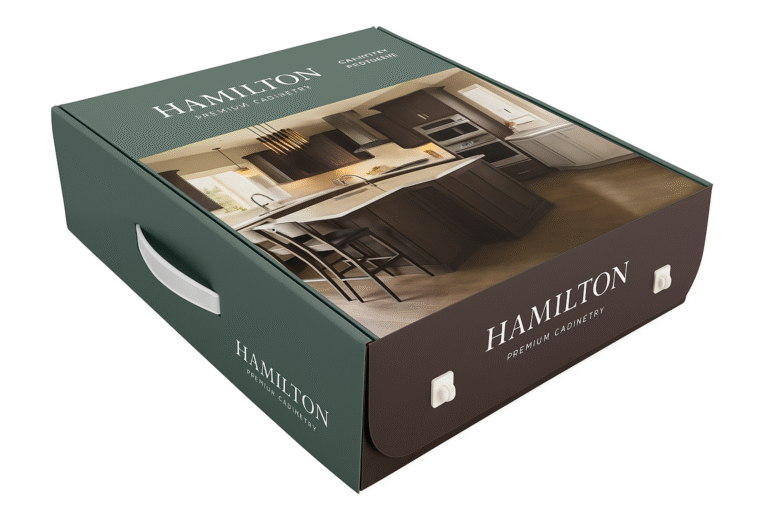

Balance Design with Function

Your print layout should enhance the box, not interfere with it. Avoid placing fine graphics near flaps, folds, or high-stress areas where cracking or misalignment can occur.

Consider Print Inside the Box

Want to wow customers or reinforce your brand? Add inside print for messaging, graphics, or product instructions. It adds impact—especially for e-commerce or subscription boxes.

Always Review a Physical Proof (If Possible)

Before full production, ask for a printed sample or digital proof to catch any errors in layout, registration, or color. This step can save time, cost, and frustration down the line.

Final Thoughts

Printing on corrugated boxes adds incredible value—but only if it’s done right. From selecting the right method to preparing artwork properly, these print tips help ensure your packaging performs as well as it looks.

Need guidance on printed corrugated boxes?

We’ll help you choose the best structure, material, and print approach to match your goals and your brand.

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are learning that premium doesn’t always

Home » 12 Print Tips for Corrugated Box Buyers