Home » Why You Should Choose A Hybrid Packaging Supplier?

Why You Should Choose A Hybrid Packaging Supplier?

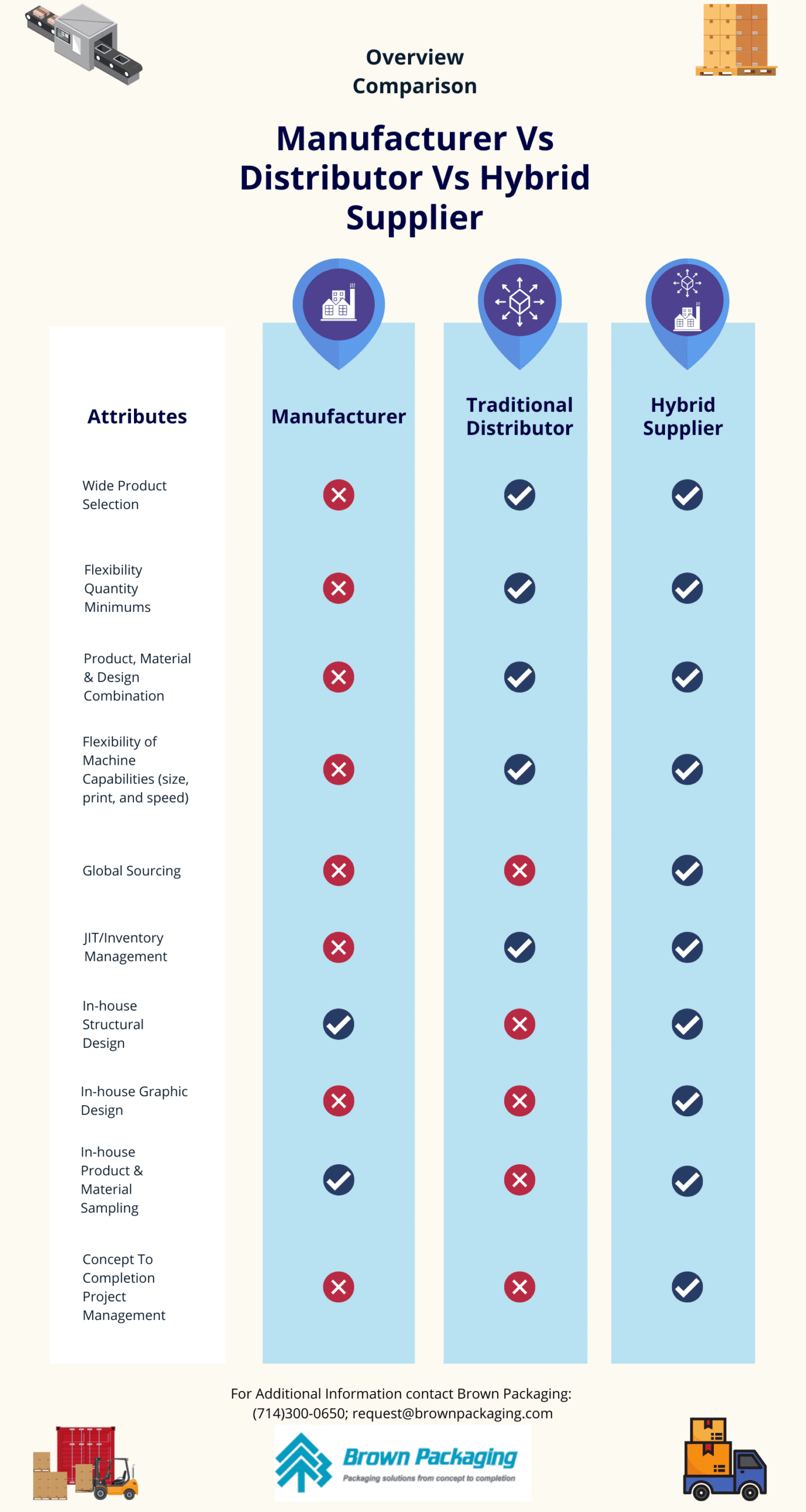

Selecting the right packaging supplier can be a daunting task, especially for newcomers in the market. The challenge often lies in balancing cost, value, product selection, order minimums, and design capabilities. While manufacturers offer direct access to production, they typically lack flexibility in product variety and additional services. On the other hand, distributors provide more options and flexibility but may lack direct control over production specifics. This is where hybrid packaging suppliers come into play, offering the best of both worlds.

Understanding the Options: Manufacturer vs. Distributor vs. Hybrid

Packaging Manufacturer

Manufacturers are the primary source for packages, offering a direct line to the production process without a middleman. This direct relationship can lead to a more streamlined process and potentially lower costs. However, manufacturers often specialize in specific types of packaging and may not offer the breadth of services or customization that some businesses require.

Advantages

- Streamlined production process

- In-house structural design team

- In-house product and material sampling

- Potentially lower costs due to direct sourcing.

- Specialized production capabilities.

Disadvantages

• Only offers 1 or a few products

• Has specific order minimums (can be high or can be low)

• Lack of flexibility in combining designs, materials, and other products (inserts, graphics, print options, finishes, and more)

• No inventory management or just in time delivery (JIT)

• No graphic design capabilities.

• Global sourcing: cannot offer prices offered overseas

Traditional Packaging Distributor

Distributors act as intermediaries who source from various manufacturers, providing a broader range of products and greater flexibility. They can cater to clients who need diverse materials and design options under one roof, often with lower minimums than direct manufacturers.

Advantages

• Wide product selection

• Flexible quantity minimums

• Product, material, and design combination

• Flexibility of machine capabilities (size, print, speed, and more)

• JIT/Inventory Management Services

Disadvantages

• No in-house graphic design team

• No in-house product and material sampling

• Does not globally source

• No project management from concept to completion

The Hybrid Packaging Supplier Advantage

Hybrid packaging suppliers combine the strengths of both manufacturers and distributors. They maintain control over the manufacturing process while offering the flexibility and variety typically associated with distributors. This model allows for a more tailored approach to packaging solutions, addressing specific needs without the typical trade-offs associated with other supply routes.

Benefits of Choosing a Hybrid Supplier:

- Comprehensive Solutions: Hybrid suppliers manage the entire process from design through production, ensuring that all aspects of packaging are harmonized.

- Customization and Flexibility: They offer the customization capabilities of manufacturers with the product variety and flexibility of distributors.

- Cost-Effectiveness: By managing both production and supply, hybrid suppliers can optimize costs across the supply chain, potentially offering more competitive pricing.

- Reduced Lead Times: Integrating services under one roof can reduce the time from design to delivery.

- Quality Control: With direct involvement in manufacturing and design, hybrid suppliers can ensure higher standards of quality control.

Ideal for Complex Projects

Hybrid suppliers are particularly beneficial for clients with complex packaging needs. They are equipped to handle intricate designs that require a blend of different materials and technologies. Additionally, they can provide valuable input during the design phase to ensure that the packaging is not only visually appealing but also functional and compliant with any necessary regulations.

Conclusion

For businesses looking to streamline their packaging procurement process without sacrificing quality or flexibility, hybrid packaging suppliers represent an optimal choice. They eliminate the inefficiencies commonly encountered when dealing with separate manufacturers and distributors, providing a seamless, cost-effective, and highly adaptable packaging solution.

In today’s market, where efficiency and adaptability are paramount, partnering with a hybrid packaging supplier can give businesses a significant competitive edge. By offering tailored solutions that meet specific packaging needs, hybrid suppliers ensure that their clients can focus on their core products without worrying about the complexities of the packaging process.

If you are interested in working with a hybrid packaging supplier, then partner with Brown Packaging today to get started.

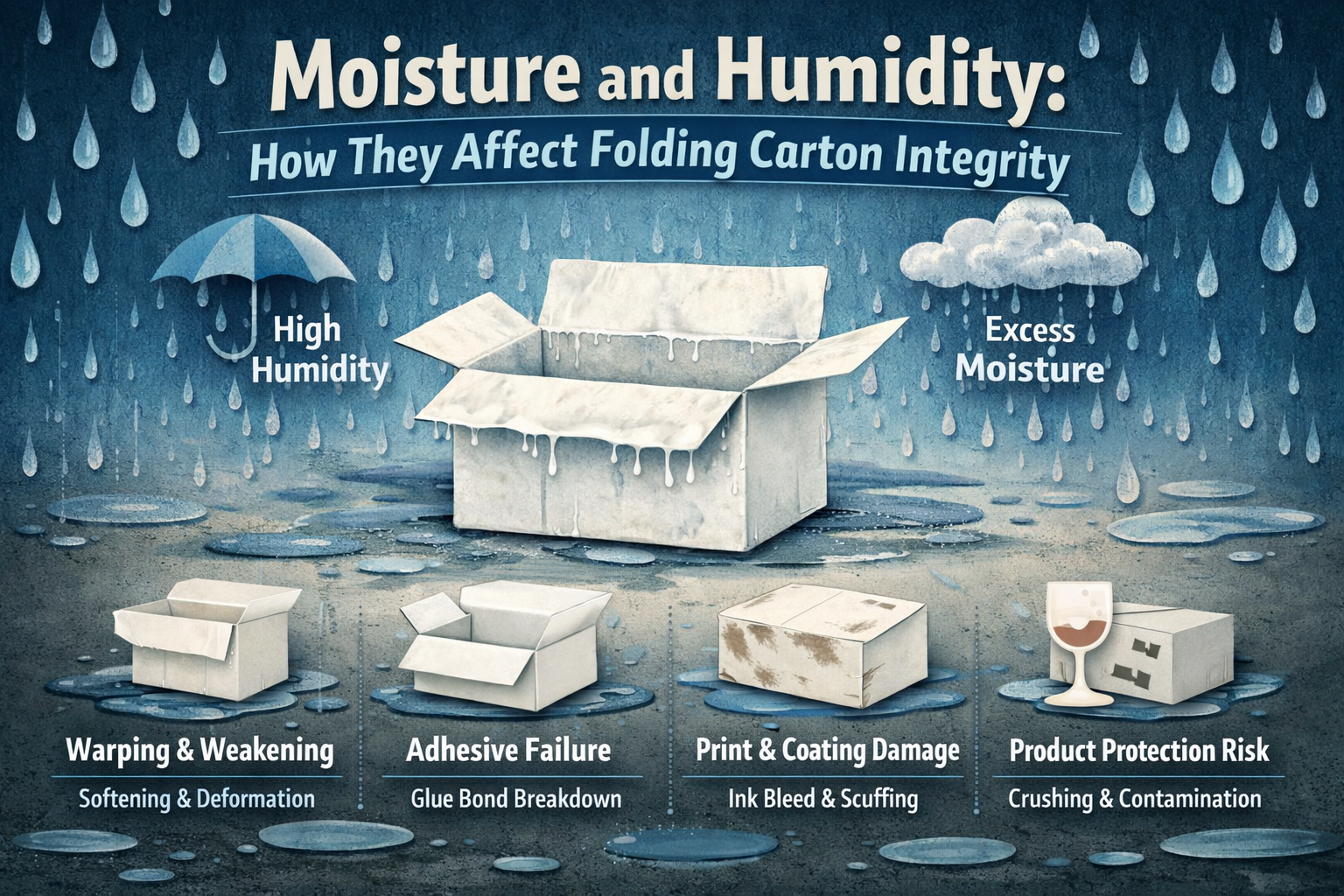

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Why You Should Choose A Hybrid Packaging Supplier?

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies