Home » Understanding the Thermoform Packaging Process

Understanding the Thermoform Packaging Process

Thermoform packaging is the backbone of numerous sectors including food, pharmaceutical, electronics, cosmetics, and consumer goods, to name a few. Its high adaptability and customizability make it an unparalleled choice for businesses around the globe. This blog post seeks to dive deeper into the world of this unique process, exploring its labyrinthine facets.

Thermoform Packaging: A Basic Overview

Before we delve deeper, let’s first understand what thermoform packaging is. This process involves heating plastic sheets until they reach a pliable forming temperature. Once the material is pliable, it’s then formed into a specific shape using a mold. After the forming process, the plastic is trimmed and converted into finished packages. Common examples of thermoform packaging that you might encounter in your daily life include blister packs, clamshells, trays, and even innovative designs like trap packs.

A Closer Look at the Types of Thermoform Packaging

There are various types of thermoform packaging, each fulfilling a unique role in different industries. The most common types include blister packs, clamshells, trays, and the emerging trend of trap packs.

Blister Packs: The Pharmaceutical Industry’s Favorite

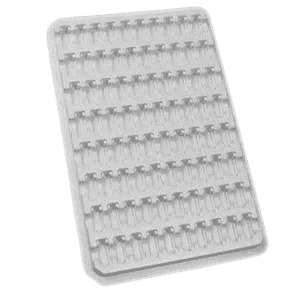

Blister packs are a ubiquitous sight in the pharmaceutical sector. They are most commonly used for packaging pills, capsules, or lozenges. A blister pack is made from a formable web, typically a thermoformed plastic, which is shaped into a cavity or pocket designed to securely hold the product.

Clamshells: Versatile and Secure

Clamshells, as the name suggests, are a type of packaging that resembles a clam in its structure. This form of packaging features two halves, which are connected through a hinge area. This design allows the packaging to open and close in a manner similar to a clamshell.

Trays: A Jack of All Trades

Trays represent another versatile form of thermoform packaging. These are extensively used to hold a plethora of items ranging from ready-to-eat meals in the food industry to various components in the electronics industry.

Trap Packs: Innovative Consumer Goods Packaging

Trap packs are an emerging trend in consumer goods packaging. They combine the advantages of thermoform packaging with innovative design elements, often featuring traps or compartments that enhance product organization and presentation. Trap packs are gaining popularity in industries where product visibility, organization, and aesthetics are crucial.

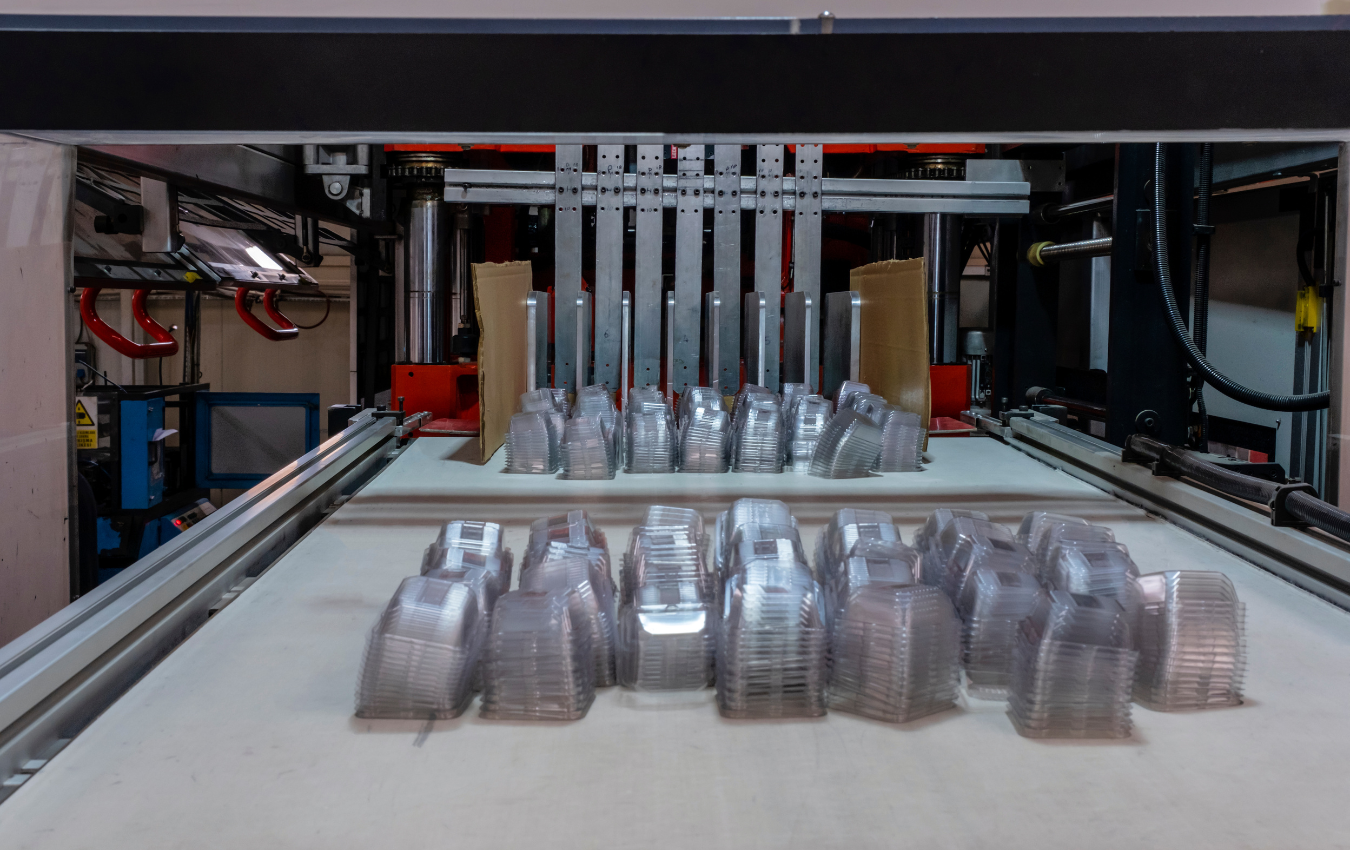

The Detailed Thermoform Packaging Process

Thermoforming packaging might seem straightforward, but it’s a complex process involving multiple stages. Each stage plays an integral role in crafting the final product.

The Salient Advantages of Thermoform Packaging

Thermoform packaging boasts numerous advantages. One of its most striking benefits is its high degree of customization. The process allows for virtually any shape to be achieved, making it apt for a wide variety of products, including the consumer goods sector.

Another notable advantage of thermoform packaging is its cost-effectiveness. The materials utilized in this process are relatively inexpensive, and the production process is highly efficient. The packaging’s lightweight nature also contributes to a decrease in shipping costs.

Transparency is yet another critical benefit. The clear nature of thermoform packaging allows potential consumers to view the product without needing to open the packaging. This quality makes thermoform packaging particularly appealing in the retail sector, especially for consumer goods where product visibility is a key selling point.

Wrapping It Up

Thermoform packaging is a multifaceted and versatile process that plays an indispensable role across a wide array of industries, including consumer goods. Understanding its intricate process and myriad benefits allows businesses to utilize this technology optimally, improving their product presentation, ensuring product safety, and boosting their profitability. As we continue to witness an evolution in the world of packaging, thermoform packaging stands firm as a reliable and efficient solution, adapting to the ever-changing demands of the consumer goods market.

If you are interested in thermoform packaging, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Understanding the Thermoform Packaging Process

The world of packaging has seen tremendous innovation over the years. With the increasing emphasis on product safety, hygiene, sustainability, and overall aesthetic appeal, manufacturers

Thermoforming is a critical process in the manufacturing of diverse products, especially prominent in the packaging industry. This guide offers a detailed examination of the

Blister packaging plays an indispensable role in various sectors, especially in the pharmaceutical, food, and consumer goods industries. It provides a user-friendly and secure mode