Home » Understanding the Role of Edge Protectors

Understanding the Role of Edge Protectors

The world of packaging is an intricate system of components working together to ensure products reach consumers in pristine condition. Many packaging elements such as tape, stretch film, or boxes are commonplace in our daily lives. However, in the grand scheme of packaging, one hero often goes unnoticed: the humble edge protector. This article aims to shine a spotlight on the essential but underappreciated role of edge protectors in the realm of packaging.

The Fundamentals: What are Edge Protectors?

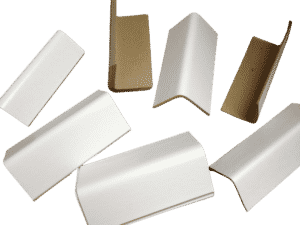

Edge protectors, often referred to as corner protectors, edge guards, or angle boards, are industrial packaging materials designed to safeguard the corners and edges of goods during storage and transportation. They are usually made from sturdy materials like plastic, metal, or most commonly, recycled cardboard. Edge protectors may appear straightforward and mundane, but they hold the essential task of shielding the products from harm and ensuring secure delivery.

The Critical Role of Edge Protectors in Packaging

Edge protectors are not just additional packaging components; they’re integral to maintaining the integrity of the packaged goods. Here’s why:

Damage Prevention

The primary purpose of edge protectors is to shield the vulnerable corners and edges of products from damage during transit. By reinforcing these vulnerable points, they decrease the likelihood of the product being affected by impacts, vibrations, or abrasions.

Load Stability

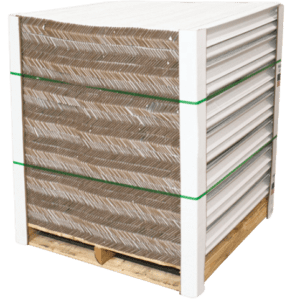

Edge protectors help maintain the stability of palletized goods during transit. They enable better load distribution and prevent shifting or toppling of products, making transport safer and more efficient.

Strapping Protection

Edge protectors also act as a buffer between strapping materials and the product, distributing the pressure applied by strapping evenly and preventing indentation or damage to the product.

Enhanced Product Image

By minimizing the risk of product damage, edge protectors indirectly contribute to preserving a company’s reputation. Receiving goods in perfect condition enhances customer satisfaction, promoting a positive product and brand image.

The Environmental Impact: Sustainability in Focus

An often-overlooked aspect of edge protectors is their contribution to sustainable packaging practices. Many edge protectors, especially those made from recycled cardboard, align with the push towards eco-friendly packaging. They are recyclable and biodegradable, reducing the overall environmental footprint of packaging. Thus, the use of edge protectors aligns with the growing consumer demand for sustainable business practices.

The Economic Perspective: Cost-Efficiency in Packaging

Edge protectors are cost-effective packaging solutions. They reduce the risk of product damage and associated costs of replacements or refunds. By ensuring load stability, they allow more efficient use of transportation space, saving costs in the long run. Moreover, being made from cost-effective materials like recycled cardboard, they don’t add significantly to the overall packaging expenses.

Conclusion: The True Value of Edge Protectors

In the world of packaging, it’s easy to overlook the quiet contributors like edge protectors. However, their role in preventing damage, promoting sustainability, and enhancing cost efficiency is invaluable. They may be unsung heroes, but the quality of the product delivery wouldn’t be the same without them. As we strive towards creating efficient, sustainable packaging solutions, the significance of edge protectors is likely to grow even more. So, the next time you see a shipment arrive in pristine condition, take a moment to appreciate the hidden champions of packaging: the edge protectors.

If your interested in edge protectors, stock or custom, the contact Brown Packaging today to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » Understanding the Role of Edge Protectors

As a packaging buyer, it is important to understand the regulations and requirements surrounding food labels to ensure that the packaging you purchase complies with

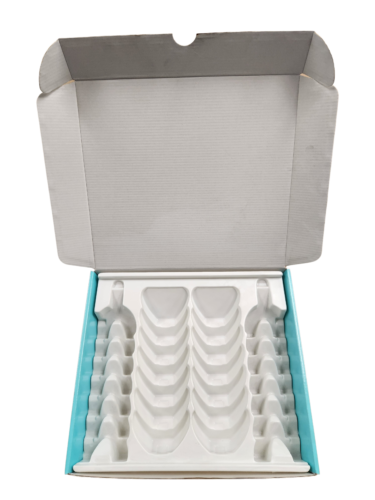

Custom box inserts are used to ensure your products are secure inside your box throughout the supply chain. They are used to keep your product

As tariff changes reshape global trade, packaging buyers moving production from China to the U.S. or nearshore regions face a new challenge: supplier qualification. Transitioning