Home » Understanding Corrugated Board: Single Wall, Double Wall, and Triple Wall Packaging

Understanding Corrugated Board: Single Wall, Double Wall, and Triple Wall Packaging

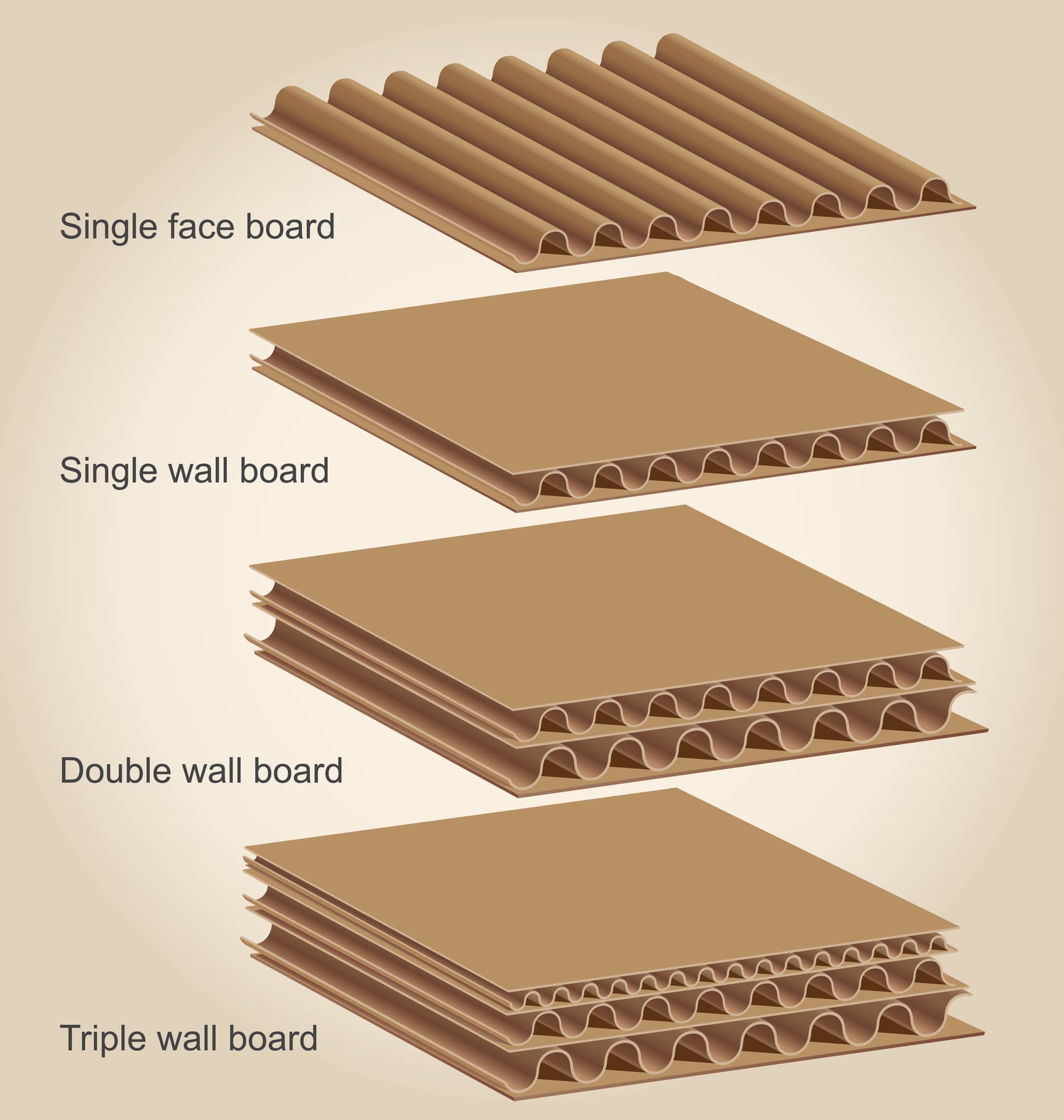

When it comes to packaging, boxes made from a material called corrugated board are among the most commonly used types today. Corrugated board consists of a fluted sheet sandwiched between two flat sheets of paperboard. This type of board is available in different grades and thicknesses, and is classified into three types: single wall, double wall, and triple wall.

Single Wall Board

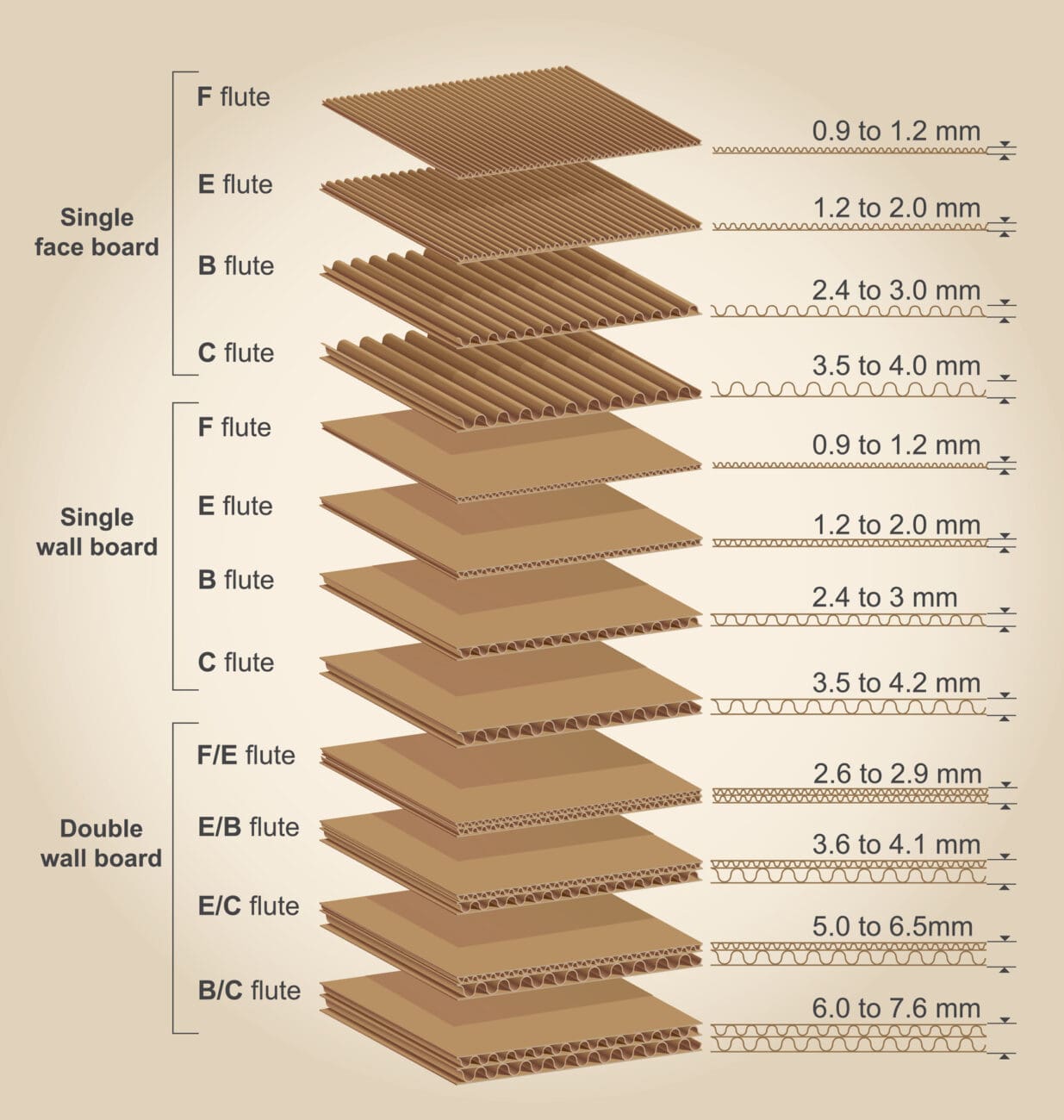

Single wall board is the most basic type of corrugated board, consisting of a single layer of fluted paperboard sandwiched between two flat sheets of paperboard. Single wall board is available in different grades and thicknesses, and is ideal for packaging applications that require a lightweight and cost-effective solution. It is often used for shipping and storing small items such as books, clothing, and electronics, as well as for product displays, storage bins, and mailers.

Double Wall Board

Double wall board is made by combining two layers of fluted paperboard with three flat sheets of paperboard. This type of board is thicker and more durable than single wall board, and is ideal for packaging applications that require extra protection and strength. It is often used for shipping and storing heavier items such as appliances, furniture, and automotive parts, as well as for industrial packaging, retail displays, and point-of-purchase displays.

Triple Wall Board

Triple wall board is the thickest and strongest type of corrugated board, made by combining three layers of fluted paperboard with four flat sheets of paperboard. This type of board is ideal for packaging applications that require maximum protection and strength. It is often used for shipping and storing extremely heavy items such as machinery, equipment, and bulk products, as well as for pallet boxes, crates, and reusable containers.

Choosing the Right Type of Board

When choosing the type of board for packaging, factors such as the weight and size of the product being shipped or stored, the shipping and handling conditions, and the intended use of the packaging should be considered. Single wall board is suitable for smaller and lighter items, while double wall or triple wall board is necessary for heavier and larger items that require extra protection and strength. For products that require maximum protection against shock, vibration, and impact, triple wall board is the best choice.

Summary: Corrugated Boards Explained

In conclusion, corrugated board is a versatile packaging material that offers various options for different packaging needs. By selecting the right type of board, businesses can ensure that their products are properly protected during transportation and storage.

If you are interested in any stock or custom corrugated packaging, then partner with Brown Packaging today to get started.

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In

Home » Understanding Corrugated Board: Single Wall, Double Wall, and Triple Wall Packaging

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and

The weight a corrugated box can hold depends on factors such as box construction, material grade, flute size, and box dimensions. Corrugated boxes are designed

In the world of shipping and storage, the term “Gaylord box” often comes up, especially in industries that deal with bulk materials and goods. But