Home » The Importance of Ease of Assembly in Packaging

The Importance of Ease of Assembly in Packaging

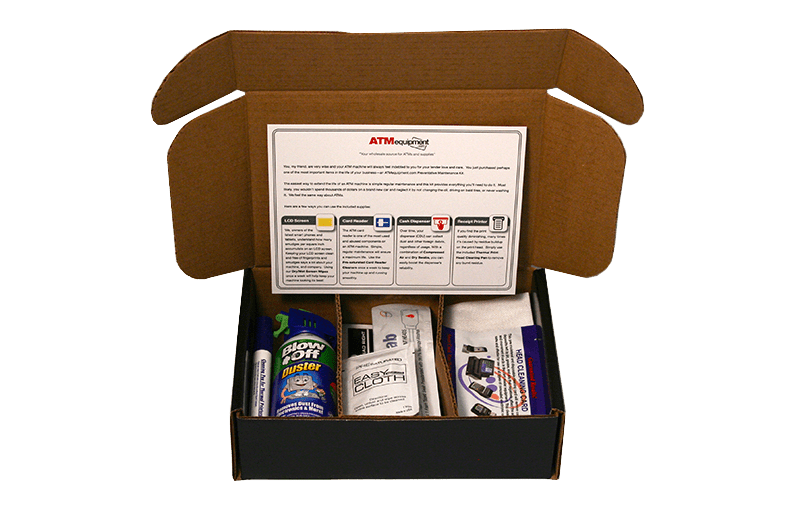

In the fast-paced world of retail and e-commerce, the ease of assembly in packaging plays a pivotal role in the overall efficiency and customer satisfaction. Simple and efficient packaging is not just a convenience; it’s a crucial factor that can significantly impact a business’s operational efficiency and the customer’s unboxing experience. This blog post explores the various aspects of ease of assembly in packaging and its wide-ranging implications.

Why Ease of Assembly Matters

The efficiency of packaging assembly directly affects the speed and cost of the production process. For businesses, especially those with high-volume shipments, packaging that is quick and easy to assemble can lead to significant time and cost savings. Moreover, for the end consumer, easy-to-assemble packaging enhances the unboxing experience, contributing to overall satisfaction and brand perception.

Implications for Operational Efficiency

- Reduced Labor Costs: Packaging that is simple to assemble requires less manual labor, reducing the cost of packaging operations.

- Faster Turnaround Times: When packaging can be assembled quickly, products can be packed and shipped out more rapidly, increasing the throughput of orders.

- Minimized Error Rates: Simplified assembly processes reduce the likelihood of errors during packaging, leading to fewer returns and customer complaints.

Enhancing Customer Experience

- User-Friendly Unboxing: Easy-to-assemble packaging also means easy-to-open packaging. A hassle-free unboxing experience is highly valued by customers and can be a deciding factor in repeat purchases.

- Brand Perception: Packaging that is thoughtfully designed for easy assembly reflects positively on a brand, enhancing its reputation for customer-centricity and innovation.

Sustainability Benefits

- Reduced Material Usage: Efficiently designed packaging often uses fewer materials, which is not only cost-effective but also environmentally friendly.

- Increased Recyclability: Simplified packaging structures are generally easier to disassemble and recycle, aligning with growing consumer demands for sustainable packaging solutions.

Innovation in Packaging Design

- Design for Assembly: The focus on ease of assembly has led to innovative packaging designs. For instance, self-locking mechanisms, intuitive folds, and interlocking tabs eliminate the need for additional packing materials like tape or staples.

- Material Innovations: Advances in materials also contribute to ease of assembly. Lightweight, flexible, yet sturdy materials can simplify the packaging process while ensuring product protection.

Tailoring to Product Needs

- Customized Solutions: The ease of assembly should be considered alongside the specific requirements of the product. For fragile or high-value items, the packaging might need additional protective features, which should be integrated without complicating the assembly process.

- Versatility: Ideally, packaging should be versatile enough to accommodate various product sizes or types, without compromising on the ease of assembly.

The Role of Automation

- Automated Packaging Lines: In larger operations, packaging assembly is often automated. The design of packaging needs to be compatible with automated systems, which can further enhance efficiency and reduce labor costs.

If you are interested in improving the ease of assembly of your packaging, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » The Importance of Ease of Assembly in Packaging

Corrugated Boxes are exposed to many different circumstances during packing, shipping and storage. Ensuring that your corrugated packaging is protecting your product fully is important.

When selecting the right packaging solution, it’s crucial to understand the specific uses and benefits of different types of boxes. Half Slotted Containers (HSC) and

When you think about product packaging, your mind probably jumps to traditional solutions like plastic containers, cans, or cardboard boxes. However, a dramatic shift is