Home » The Evolution of Protective Packaging Solutions

The Evolution of Protective Packaging Solutions

The fascinating world of protective packaging has seen considerable evolution over the decades. These advancements have been driven by the needs of various industries, emerging technologies, sustainability concerns, and consumer demand. In essence, protective packaging’s primary purpose remains to ensure products reach their destinations unscathed. This blog post will delve into the intriguing evolution of protective packaging solutions, tracing the industry’s trajectory from rudimentary beginnings to modern, eco-friendly innovations.

The Humble Beginnings

Packaging, in its earliest forms, was incredibly basic. The prime objective was to contain and protect goods, often food, during transportation and storage. Examples of early packaging materials include leaves, animal skins, and rudimentary wooden crates and barrels. The ancient Egyptians, for example, used reed and clay pots for packaging wine and grain.

The Industrial Revolution: A Turning Point

The advent of the Industrial Revolution in the late 18th century marked a significant milestone in the evolution of protective packaging. Mass production and global trade increased exponentially, requiring efficient and durable packaging solutions. During this period, glass containers and tin cans made their debut, offering better product preservation and protection.

The 20th Century: The Era of Plastic and Styrofoam

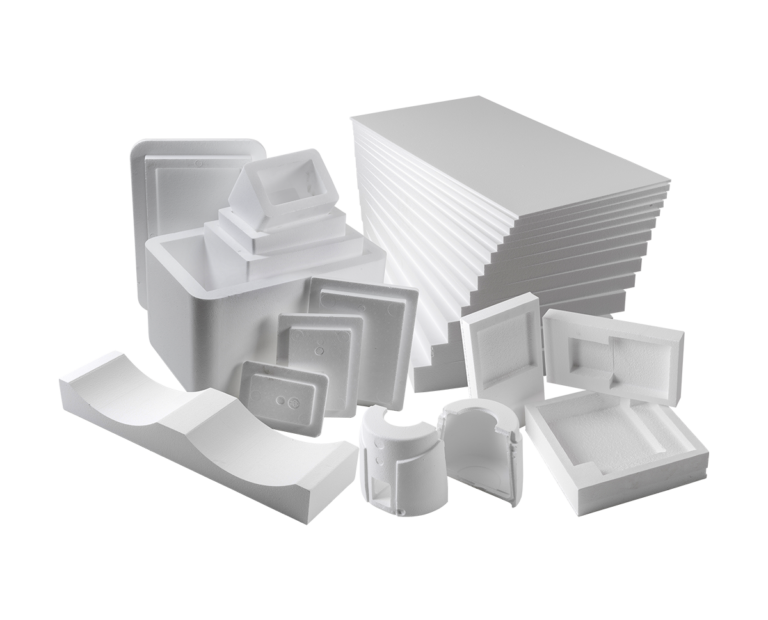

The 20th century saw a transformative shift in the packaging world, with the introduction of synthetic materials like plastic and Styrofoam. These materials offered superior protection, were lightweight, and could be molded into virtually any shape, making them ideal for a wide range of products.

Bubble wrap, invented in the late 1950s, became a popular packaging material due to its cushioning properties. Polystyrene (Styrofoam) peanuts soon followed, providing a cost-effective solution for filling voids in packaging and preventing product movement.

Towards Eco-friendly Solutions

Despite their protective qualities, materials like plastic and Styrofoam became a significant source of environmental concern due to their non-biodegradable nature. With increased awareness of environmental issues and consumer demand for sustainable practices, the packaging industry began exploring eco-friendly alternatives.

This shift has led to the development of biodegradable packaging materials, such as cornstarch and mushroom packaging. Cornstarch, a renewable resource, is used to create bioplastic, which has similar protective qualities to conventional plastic but decomposes naturally over time. Mushroom packaging, made from mycelium (the root structure of mushrooms), provides a sustainable and compostable alternative to polystyrene.

Embracing Technology: Modern Protective Packaging Solutions

The 21st century has welcomed the use of technology in creating innovative protective packaging solutions. Cutting-edge options like air pillows and inflatable packaging are grew in popularity. These solutions are not only effective in protecting products but also reduce the volume of packaging materials required, leading to cost and environmental benefits.

Technology has also enabled the use of advanced analytics in packaging. Companies can use data to optimize packaging design, improve protection, reduce waste, and enhance customer satisfaction.

The Future of Protective Packaging Solutions

As we look ahead, the future of protective packaging appears to be driven by two major trends: sustainability and customization. With environmental consciousness at an all-time high, the push for biodegradable, recyclable, and reusable packaging materials will continue to grow.

Additionally, with the advent of technologies like 3D printing and AI, we can expect to see an increase in customized protective packaging solutions. This allows for packaging to be tailored to the unique needs of each product, improving protection and customer satisfaction.

If you are interested in protective packaging solutions, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » The Evolution of Protective Packaging Solutions

Polyvinyl chloride, commonly known as PVC, is a widely used plastic in the packaging industry, celebrated for its versatility and durability. PVC’s unique properties make

In the world of e-commerce and supply chain management, the need for reliable packaging materials cannot be overstated. From the careful encasing of fragile items

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall