Home » The Essential Role of Secondary Packaging in Product Success

The Essential Role of Secondary Packaging in Product Success

Secondary packaging plays a vital role in the supply chain, influencing marketing, protection, and logistics. It’s an integral component for businesses in various industries. In this blog, we explore the essence of secondary packaging, its significance, various types, applications, and its distinction from primary and tertiary packaging.

Understanding Secondary Packaging

Secondary packaging encases the primary packaging of a product. It doesn’t come into direct contact with the product but serves as an additional protective layer. This layer of packaging, often seen on store shelves, is crucial in both marketing and safeguarding products during their journey from manufacturer to consumer.

The Significance of Secondary Packaging

The role of secondary packaging extends beyond mere protection. It is an essential element for branding and marketing, drawing consumer attention with its design and graphics. It also simplifies handling, storage, and transportation of products, particularly in bulk. Additionally, secondary packaging can be a valuable source of product information, such as instructions or ingredients. In today’s environmentally conscious market, eco-friendly secondary packaging options are increasingly important for both brand image and environmental responsibility.

Different Types of Secondary Packaging

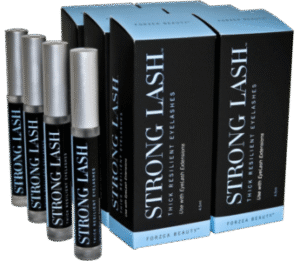

There’s a variety of secondary packaging materials and styles, each suited to different product types and industries. Common forms include boxes and cartons, which offer robust protection and ample branding space. Shrink wrap is great for bundling items like beverages together. Paperboard packaging, often seen in cosmetics and pharmaceuticals, strikes a balance between protection and aesthetic appeal. Plastic cases are another option, offering durability for items like electronics and tools.

Applications Across Industries

Secondary packaging finds its place in diverse sectors. In the food and beverage industry, it’s crucial for the safe transportation and storage of items. The pharmaceutical industry relies on it for additional protection and information dissemination for medications. In cosmetics and personal care, it enhances brand visibility and safeguards delicate products. For electronics, it provides necessary protection against various environmental factors.

Comparing Packaging Levels

Secondary packaging differs from primary and tertiary packaging in its focus and function. While primary packaging is in direct contact with the product, such as a beverage bottle, and is mainly concerned with preservation and initial presentation, secondary packaging focuses more on branding, bulk handling, and additional protection. Tertiary packaging, on the other hand, is used for larger-scale handling and transportation, involving items like pallets and crates.

Conclusion

Secondary packaging is a multifaceted element in product distribution, crucial for protection, presentation, and logistics. It’s not just about safeguarding the product; it’s about enhancing brand value, ensuring product safety, appealing to the target audience, and considering the environmental impact. Thoughtful secondary packaging choices can significantly influence a product’s success in the market.

If you are interested in secondary packaging, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » The Essential Role of Secondary Packaging in Product Success

In packaging, foam isn’t just about initial protection — it’s about maintaining performance over the entire shipping or storage cycle. Compression set and recovery characteristics

Transitioning from off-the-shelf packaging to custom solutions is a significant milestone for many businesses. This shift not only aligns packaging more closely with brand identity

When browsing a retail store many of us have probably noticed that most products are packaged in a box, whether they are on the shelf