Home » The Complete Guide to Choosing Custom Die-Cut Foam for Packaging

The Complete Guide to Choosing Custom Die-Cut Foam for Packaging

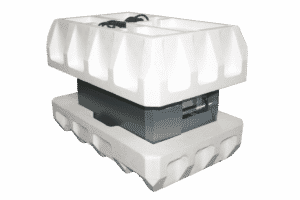

Packaging is a crucial aspect of any business that deals with physical products. Custom die-cut foam is a popular packaging material that offers excellent cushioning and protection to the product during transportation and storage. However, before buying custom die-cut foam for packaging, packaging buyers (businesses) should consider several factors to ensure that they choose the right foam for their product.

Foam Types

Packaging buyers should know that there are different types of foam available in the market, including polyethylene (PE) foam, cross-linked polyethylene (XLPE) foam, polyurethane (PU) foam, and polystyrene (PS) foam. Each type of foam has its own set of characteristics, such as density, thickness, color, and durability. The weight and fragility of the product should be considered when selecting the right type of foam.

Customization

Custom die-cut foam offers endless possibilities in terms of customization. The packaging buyer can choose from a wide range of foam colors, thicknesses, and densities to create a unique packaging solution for their product. The foam can also be cut into various shapes and sizes to fit the product snugly. Partner with a foam manufacturer to design a custom foam insert that meets their specific packaging requirements.

Protection

The primary purpose of custom die-cut foam is to provide protection to the product during transportation and storage. The foam should be able to absorb shock and vibration, preventing any damage to the product. You should ensure that the foam is of high quality and has the right density to provide adequate cushioning to the product. The foam should also be able to withstand temperature changes, humidity, and moisture, especially if the product is being shipped long distances.

Foam Density and Thickness

The foam’s density and thickness are essential factors that affect the cushioning and protection offered by the foam. Low-density foam is suitable for lightweight products, while high-density foam is suitable for heavy and fragile products. Thicker foam is generally better for heavy and fragile products, while thinner foam is suitable for lightweight products. The packaging buyer should work with the foam manufacturer to determine the right foam density and thickness for their product.

Foam Color

Custom die-cut foam is available in a wide range of colors, which helps brands utilize their colors. The foam color can also be used to enhance the product’s presentation and increase brand recognition. However, you should keep in mind that certain foam colors may be more expensive than others.

Foam Manufacturing Process

The foam manufacturing process is an important aspect that packaging buyers should consider when choosing a foam supplier. The foam manufacturing process can affect the foam’s quality, consistency, and lead times. Look for a foam manufacturer that uses the latest manufacturing technology and equipment for accuracies and tolerances. It has a proven track record of delivering high-quality foam products. The foam manufacturer should also have a reliable and efficient supply chain to ensure on-time delivery of the foam.

Cost

Custom die-cut foam is generally more expensive than other types of packaging materials. The packaging buyer should factor in the cost of the foam when budgeting for their packaging needs. However, the cost of the foam can be offset by the benefits it offers in terms of product protection, branding, and customer satisfaction. It is important to consider the value of the foam in relation to the product’s value and the customer’s perceived value.

Sustainability

Sustainability is an increasingly important aspect of packaging, and packaging buyers should consider the environmental impact of the foam they choose. Foam is not biodegradable and can take hundreds of years to decompose. The packaging buyer should look for foam manufacturers that use recycled materials or have a closed-loop recycling system in place. The packaging buyer can also consider using other eco-friendly packaging materials, such as paper or biodegradable plastics, instead of foam.

If you are interested in custom foam packaging solutions, then partner with Brown Packaging today to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » The Complete Guide to Choosing Custom Die-Cut Foam for Packaging

We all want to protect our products during shipment, but are not quite sure on which product to use, often many of us find ourselves

The fascinating world of protective packaging has seen considerable evolution over the decades. These advancements have been driven by the needs of various industries, emerging

In the current competitive retail landscape, the packaging of a product plays an increasingly significant role in customer decision-making. Brands are progressively realizing the power