Home » Temporary vs. Permanent POP Displays: Pros and Cons

Temporary vs. Permanent POP Displays: Pros and Cons

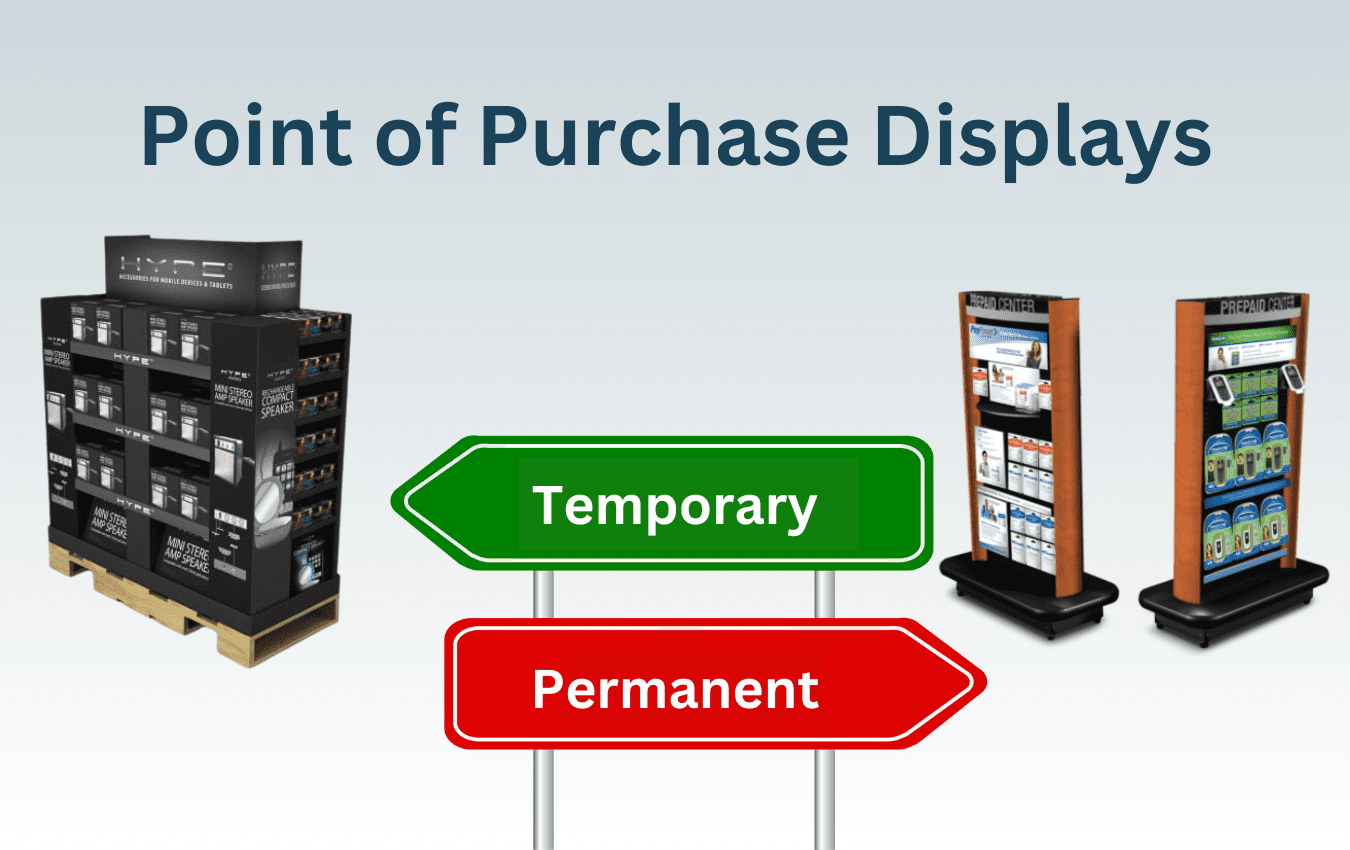

In the intricate world of retail, Point-of-Purchase (POP) displays play a critical role in influencing consumer decisions and driving sales. When it comes to choosing between temporary and permanent POP displays, retailers face a crucial decision that can significantly impact their marketing strategy and brand visibility. Each option comes with its own set of advantages and drawbacks, making it essential to understand the pros and cons of both approaches.

Temporary POP Displays

Pros

- Flexibility: Temporary displays are ideal for short-term promotions, seasonal campaigns, or product launches. They can be quickly set up and removed, allowing retailers to adapt to changing marketing strategies.

- Cost-Effective: These displays often require lower upfront costs, making them suitable for brands with budget constraints.

- Variety: Temporary displays come in various shapes, sizes, and materials, providing room for creativity and experimentation.

Cons

- Limited Durability: As the name suggests, temporary displays are not built for long-term use and may not withstand heavy wear and tear.

- Brand Consistency: Achieving consistent branding can be challenging across various temporary displays, potentially affecting brand recognition.

- Environmental Impact: Frequent replacement of temporary displays can contribute to waste and environmental concerns.

Permanent POP Displays

Pros

- Durability: Permanent displays are designed to withstand continuous use and are suitable for long-term campaigns. They offer a more robust solution that can last for years.

- Consistent Branding: Permanent displays offer a consistent brand image throughout the store, enhancing brand recognition and customer familiarity.

- Sustainability: While they may involve higher upfront costs, permanent displays can be more environmentally friendly in the long run due to their extended lifespan.

Cons

- Higher Costs: Permanent displays often require a larger investment upfront, including design, manufacturing, and installation expenses.

- Limited Flexibility: Once installed, making changes to permanent displays can be challenging and costly.

- Space Considerations: Permanent displays require dedicated space within the store, limiting flexibility in layout changes.

Making the Right Choice

The decision between temporary and permanent POP displays ultimately depends on your specific goals, budget, and brand strategy.

Temporary Displays Are Ideal When:

- You have short-term promotions or seasonal campaigns.

- You want to test different display concepts and measure their effectiveness.

- Budget constraints are a concern.

- You want to keep your displays fresh and engaging by frequently updating them.

Permanent Displays Are Ideal When:

- You have a consistent brand message that you want to convey throughout the year.

- You’re looking for a long-term solution that offers durability and sustainability.

- You have the budget for upfront investment and are willing to commit to a more substantial display presence.

- You want to establish a strong and recognizable brand presence within the store.

A Hybrid Approach

In some cases, it may be beneficial to opt for a hybrid approach, combining both temporary and permanent displays to leverage the strengths of each. For instance, permanent displays can serve as the foundation, while temporary displays are used for specific promotions or new product launches.

If you are interested in pop displays, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Temporary vs. Permanent POP Displays: Pros and Cons

Creating a successful Point of Purchase (POP) display involves thorough research and careful planning. This crucial second step in the development of a POP display

In retail, the ease with which customers can interact with products directly influences their purchasing decisions. Point of Purchase (POP) displays designed with accessibility in

Point of Purchase (POP) displays are an effective way to promote products and increase sales in retail environments. The trends for POP displays in 2023