Home » Subscription Packaging Buyers’ Checklist for 2026

Subscription Packaging Buyers’ Checklist for 2026

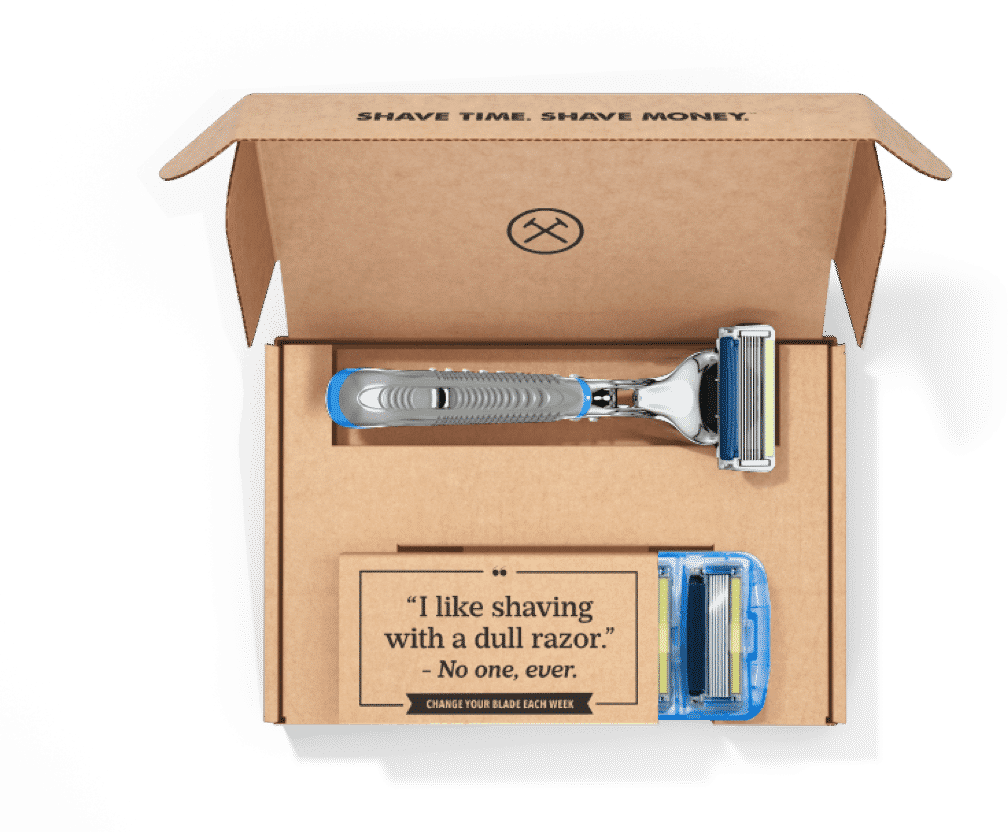

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers should review in 2026 when sourcing or redesigning subscription packaging.

Branding and Unboxing Experience

- Seasonal or rotating graphics to keep unboxing fresh.

- Premium finishes such as foil, embossing, or unique die-cuts.

- Easy-open features like tear strips for convenience.

Right-Sizing and Efficiency

- Reduce DIM charges with packaging tailored to product sizes.

- Use modular designs to cover multiple SKUs with fewer box sizes.

- Ensure packaging works with automation to speed fulfillment.

Protection and Durability

- Inserts that prevent product shifting during transit.

- ISTA-tested designs to withstand vibration and drops.

- Moisture-resistant coatings for temperature-sensitive items.

Sustainability Requirements

- FSC-certified corrugated or recycled substrates.

- Recyclable coatings or compostable options.

- Clear sustainability messaging to support consumer expectations.

Cost Control

- SKU rationalization to limit unnecessary box variations.

- Material selection that balances protection and price.

- Supplier contracts that secure pricing for seasonal peaks.

Packaging Solutions with Brown Packaging

Brown Packaging designs subscription packaging that combines branding, protection, and sustainability. From FSC-certified corrugated to custom inserts, our solutions help buyers create packaging that builds loyalty and controls costs in 2026. Contact us to review your subscription packaging program.

References

Sustainable Packaging Coalition. (2023). Subscription Packaging and Consumer Insights. Retrieved from https://sustainablepackaging.org

Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.org

International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Subscription Packaging Buyers’ Checklist for 2026