Home » Strength Testing for RSC Boxes: What Really Matters

Strength Testing for RSC Boxes: What Really Matters

RSC boxes are known for their efficiency and versatility, but their performance ultimately comes down to strength. Buyers often see numbers like ECT, BCT, and burst strength on specifications — but which tests matter most, and what do they actually measure? Choosing the right RSC depends on understanding how these tests translate to real-world shipping conditions.

Edge Crush Test (ECT)

What It Measures

- Resistance of corrugated board to edgewise compressive forces.

- Expressed in pounds per inch (e.g., 32 ECT).

Why It Matters

- Directly tied to stacking strength and pallet performance.

- The most common metric used in North America for corrugated box strength.

Limitations

- Only measures board strength, not the full box.

- Doesn’t account for humidity, handling abuse, or long-term compression.

Box Compression Test (BCT)

What It Measures

- Maximum load a finished box can withstand before collapsing.

- Accounts for box size, design, and board strength.

Why It Matters

- Most accurate predictor of how an RSC will perform in stacking and pallet loads.

- Useful for optimizing board grades to reduce cost without risking damage.

Limitations

- Requires lab testing of actual boxes.

- Not always practical for small-volume or custom runs.

Burst Strength (Mullen Test)

What It Measures

- Pressure required to rupture corrugated board by puncture.

- Historically the go-to test before ECT became standard.

Why It Matters

- Still relevant for industries where puncture or tearing is a higher risk than compression (e.g., heavy parts, bulk industrial goods).

Limitations

- Doesn’t reflect stacking strength.

- Often replaced by ECT in modern logistics.

Translating Tests to Real-World Performance

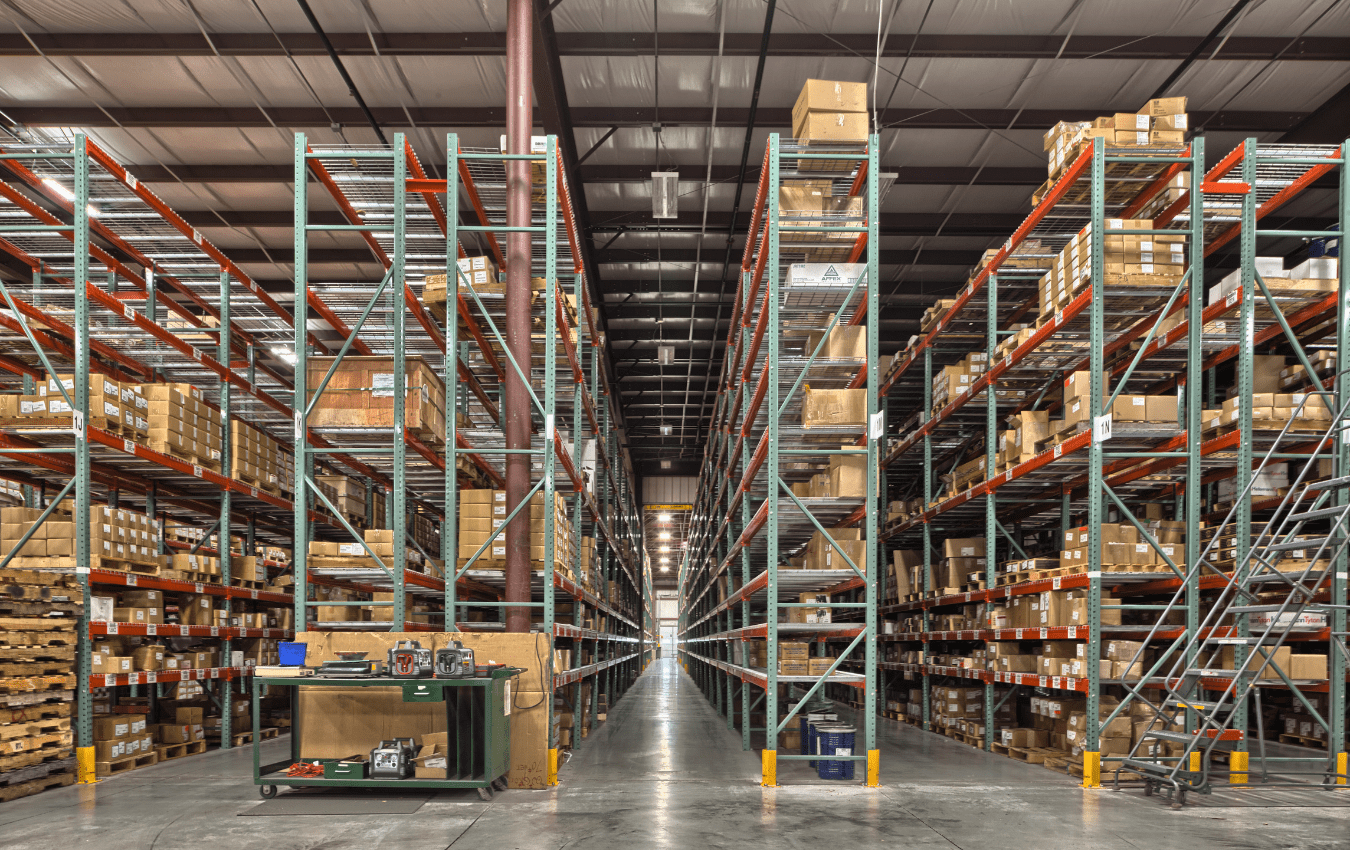

- High-Volume E-Commerce: ECT rating is usually the key metric, especially for stacking in warehouses.

- Heavy Industrial Products: Burst strength may be more relevant if products are sharp or heavy.

- Palletized Loads: BCT is the best indicator, as it measures box and board performance together.

- Moisture & Humidity: None of the above tests fully account for water absorption — additional treatments or coatings may be necessary.

Buyer Takeaway

- Look for ECT when evaluating basic strength requirements.

- Prioritize BCT if your shipments are palletized or stacked in warehouses.

- Consider burst strength if your products are heavy, sharp, or prone to puncture risks.

- Remember: lab tests are only part of the story — real-world conditions like humidity, handling, and long-term storage will also affect performance.

References

- Fibre Box Association. (2023). Box Performance Standards. https://www.fibrebox.org

- TAPPI. (2024). Testing Methods for Corrugated Packaging. https://www.tappi.org

- Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Strength Testing for RSC Boxes: What Really Matters