Home » Straight Tuck End vs. Reverse Tuck: Which is the Right Choice?

Straight Tuck End vs. Reverse Tuck: Which is the Right Choice?

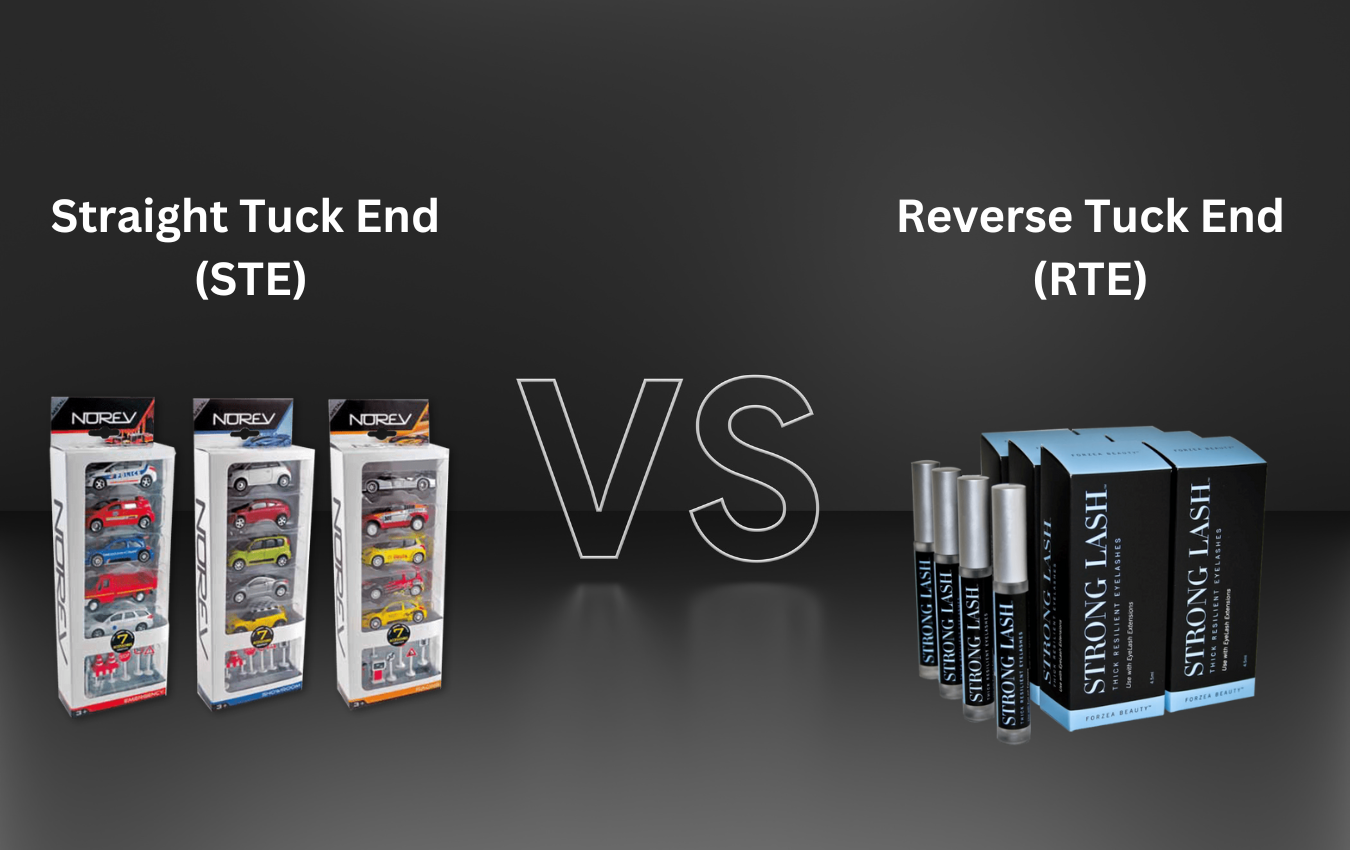

Folding cartons are a staple in the packaging industry, known for their versatility and functionality. Among the various styles available, two popular choices are the straight tuck end (STE) and reverse tuck end (RTE) cartons. Each style offers unique features and advantages that cater to different packaging needs. In this blog, we will explore the functions, features, design considerations, benefits, and applications of both straight tuck end and reverse tuck end cartons to help you make an informed decision.

Straight Tuck End (STE) Cartons

Functions and Features:

- Opening and Closing Mechanism: Straight tuck end cartons feature tuck flaps on the same side at the top and bottom of the box. These flaps can be easily tucked into the carton for closure, providing a secure seal.

- Design Versatility: STE cartons offer ample design flexibility, with options for custom die-cut windows, embossing, foil stamping, and various printing techniques. This makes them ideal for branding and product visibility.

- Ease of Assembly: These cartons are user-friendly, as they can be quickly assembled by hand, reducing labor costs in packaging lines.

Benefits:

- Secure Closure: The straight tuck design ensures that the contents remain securely enclosed within the carton, reducing the risk of tampering or damage during transit.

- Aesthetic Appeal: STE cartons can be designed with a premium look and feel, making them suitable for high-end products like cosmetics, pharmaceuticals, and luxury goods.

- Cost-Effective: They are often more cost-effective than other carton styles due to their straightforward design and ease of production.

- Inserts: STE cartons can be made with inserts that provide customizable support and protection, ideal for securing fragile items like electronics or glass during transit. They also enhance product presentation by being designed to fit the exact shape of the product, significantly improving the unboxing experience and making the carton especially appealing for gift items and luxury products where first impressions are key.

- Window Cutouts: Window cutouts in STE cartons offer product visibility, allowing consumers to view the product inside without opening the packaging, which is particularly advantageous for items where visual appeal influences purchasing decisions, such as food, toys, or beauty products. These cutouts not only enhance shelf appeal by showcasing the product and differentiating it on retail shelves but also provide customization options in terms of shape and size, aligning closely with marketing and branding strategies to create a distinctive visual identity.

Applications:

Straight tuck end cartons find wide application across various industries, including:

- Cosmetics and beauty products

- Pharmaceuticals and healthcare

- Electronics accessories

- Food and confectionery

- Apparel and clothing

Reverse Tuck End (RTE) Cartons

Functions and Features:

- Opposite Tuck Closure: Reverse tuck end cartons have tuck flaps on opposite sides of the carton. The top flap tucks into the rear panel, while the bottom flap tucks into the front panel.

- Product Accessibility: RTE cartons offer easy access to the product as both the top and bottom can be opened separately. This feature is particularly convenient for consumers.

- Design Space: These cartons provide ample space for product information, branding, and graphics on both the front and rear panels.

Benefits:

- Convenient Access: The reverse tuck design allows consumers to access the product without fully opening the carton, making it user-friendly.

- Efficient Storage: RTE cartons stack efficiently, saving space during storage and transportation.

- Versatile Applications: They are versatile and suitable for various product sizes and industries, including electronics, hardware, pharmaceuticals, and consumer goods.

Applications:

Reverse tuck end cartons are commonly used in the following industries:

- Electronics and gadgets

- Hardware and tools

- Pharmaceuticals and vitamins

- Consumer goods and retail

- Office and stationery products

Choosing the Right Carton Style: What to Include in Your Decision

When deciding between straight tuck end and reverse tuck end cartons, consider the following factors:

- Product Type: Think about the nature of your product. If it requires easy access for consumers, reverse tuck end cartons may be more suitable. For products requiring a premium presentation, straight tuck end cartons may be preferable.

- Branding and Design: Assess your branding and design requirements. If you need a larger canvas for graphics and information, reverse tuck end cartons offer more space. However, if you want an elegant and secure packaging solution, straight tuck end cartons might be the better choice.

- Window and Insert:

- Consumer Experience: Consider the end-user experience. If convenience and ease of opening are paramount, reverse tuck end cartons are designed with consumers in mind.

If you are interested in folding cartons and specific styles such as STE, RTE, auto bottom and more, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Straight Tuck End vs. Reverse Tuck: Which is the Right Choice?

Choosing a folding carton isn’t just about the graphics or the style—it’s about how the structural design and substrate work in tandem. The right combination

When browsing a retail store many of us have probably noticed that most products are packaged in a box, whether they are on the shelf

Board caliper—the thickness of paperboard—directly influences carton strength, folding behavior, print quality, and cost. Selecting the right caliper is a balancing act between performance requirements