Home » Solid Bleached Sulfate (SBS) Folding Cartons Explained: Properties and Packaging Applications

Solid Bleached Sulfate (SBS) Folding Cartons Explained: Properties and Packaging Applications

Solid Bleached Sulfate (SBS), often used under the umbrella term “paperboard,” is a common packaging material used in North America to package everyday consumer good products such as personal care, pharmaceuticals, snacks, confectionery, electronics, and other items. Typically, SBS material is used to manufacture folding cartons in addition to pads and packaging inserts.

What is Solid Bleached Sulfate?

SBS material is manufactured from hardwood and chemically pulped fibers that are bleached, refined, and formed into one or multi-ply board on fourdrinier-type paperboard machines. Once processed, the material is produced in to double sided white plain sheets.

They are coated 1 side or both sides. Coating helps to create a better surface for printing. It can be manufactured into a variety of densities to help manage material costs and strength required for product support.

Solid Bleached Sulfate Properties

SBS folding cartons have an ultra-smooth surface since the material is made with short hardwood fibers that are coated and polished, which makes a high level of quality offset lithography, flexography, and digital printing. SBS material is extremely versatile, high in quality and can be used for films, metalized foil laminations, embossing and other finishes, gluing and high-speed filling. In addition, this material can easily be manufactured in to a folding carton as it can be cleanly cut and printed with high speed.

Solid bleached sulfate is typically more costly to produce than other folding carton materials such other paperboard substrates. The durability of SBS folding cartons is adequate to hold small and lightweight items for long periods of time. However, overtime the material is susceptible to yellowing if exposed to sunlight or UV rays. Despite have good stiffness and compression capabilities, SBS folding cartons are not the most prominent in being tear resistant.

Solid Bleached Sulfate Folding Carton Applications

SBS folding cartons are highly versatile and made with quality material which makes it popular in a wide variety of packaging applications. However, due to its durability and strength limitations, SBS folding cartons are primarily used to package non-expensive, nonfragile, lightweight, and small items.

SBS folding cartons can come in many styles to help accommodate products. The most popular styles include straight tuck end (STE), reverse tuck end (RTE), auto bottom and full seal. See images below to compare the visual differences between the styles.

Straight Tuck End (STE) Folding Carton with hanging tab

Reverse Tuck End (RTE) Folding Carton with locking tab

Auto Bottom Folding Carton

Full Seal Folding Carton

Many industries such as food, electronic, medical, cosmetic use these folding cartons to display, ship and protect their products, as SBS material provides an ultra-surface and high-quality print options.

Common food packaging applications include: snacks, confectionary, cereal, bakery products and other items. For food applications, there are versions which are laminated with poly film for grease resistance.

Electronics packaging applications consist of accessories, toys, devices and more. Medical applications include medicine, devices, and other consumer goods. Beauty and personal care products supply such as eyeshadow, lipstick, lotion, face cream, serums and oils are packaged into SBS folding cartons.

Summary: Solid Bleached Sulfate Folding Cartons

Ultimately, SBS folding cartons are extremely versatile in customization and are primarily used by different industries to package a wide variety of items in highly competitive retail environment with its high visual graphics and smooth quality surface.

If you are interested in folding cartons, bringing your product to retail or improving an existing product’s packaging, then contact Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Solid Bleached Sulfate (SBS) Folding Cartons Explained: Properties and Packaging Applications

Color plays a pivotal role in product packaging, serving not just an aesthetic purpose but also communicating values, emotions, and expectations to the consumer. Effective

In the diverse landscape of product packaging, understanding how to effectively target different demographics, including gender-specific audiences, is crucial. Packaging is not just a protective

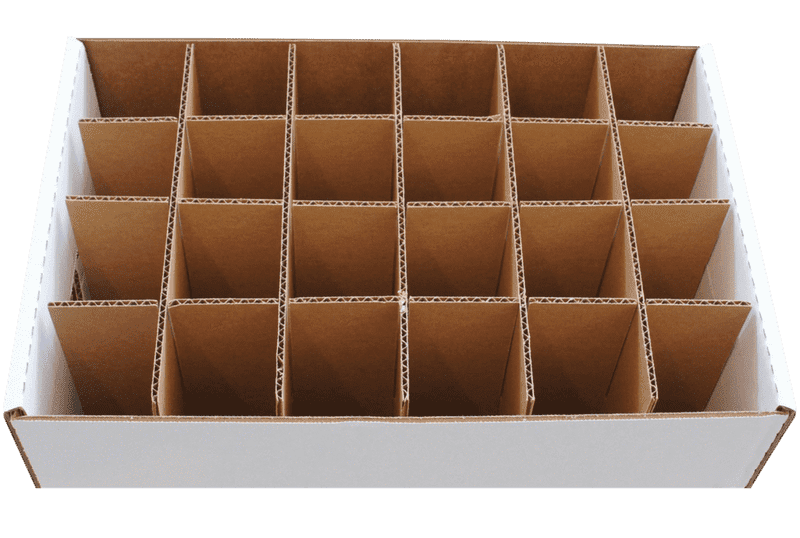

Corrugated partition inserts are an innovative packaging solution that can significantly enhance the functionality and efficiency of boxes. These inserts are made from corrugated cardboard,