Home » Single-Color vs. Multi-Color Printing in Packaging: Pros and Cons

Single-Color vs. Multi-Color Printing in Packaging: Pros and Cons

Packaging is an essential aspect of any product’s marketing strategy. It is often the first point of contact with the consumer and can greatly influence their decision to purchase. One crucial element of packaging is color. The use of color in packaging can affect a consumer’s perception of a product, and it is important to choose the right color scheme for your product packaging. In this blog, we will discuss the differences between single and multi-color print in packaging and the pros and cons of each.

What is Single-Color Printing?

Single-color printing is a printing method that uses only one color to create the design or image on packaging. It has several advantages and disadvantages.

Advantages of Single-Color Printing

- Cost-effective: Single-color printing is more cost-effective than multi-color printing since it requires only one ink color and printing plate. This makes it a good option for brands that want to save money on their packaging design.

- Consistent: Since single-color printing uses only one ink color, it is easier to maintain consistency in color throughout the entire print run. This is important for brands that want their packaging to look the same across all their products.

- Vibrant: The ink used in single-color printing is typically opaquer, creating a bold and vibrant image. This makes it a great option for packaging that needs to stand out on the shelves.

Disadvantages of Single-Color Printing

- Limited design options: Single-color printing is limited to using only one ink color, which can limit the design options available. This means that it may not be suitable for packaging designs that require a range of colors or complex images.

- Less detail: Single-color printing is not well suited for detailed designs or images. This is because it is difficult to create shading or gradation with just one color.

- Lack of contrast: With only one color, it can be challenging to create contrast between different elements of the design. This can make the packaging design look flat and uninteresting.

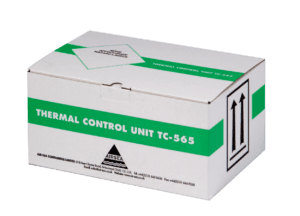

Examples of Single-Color Printing

- Black and white printing: Black and white printing is a classic example of single-color printing. It is a great option for packaging designs that want to create a vintage or nostalgic feel.

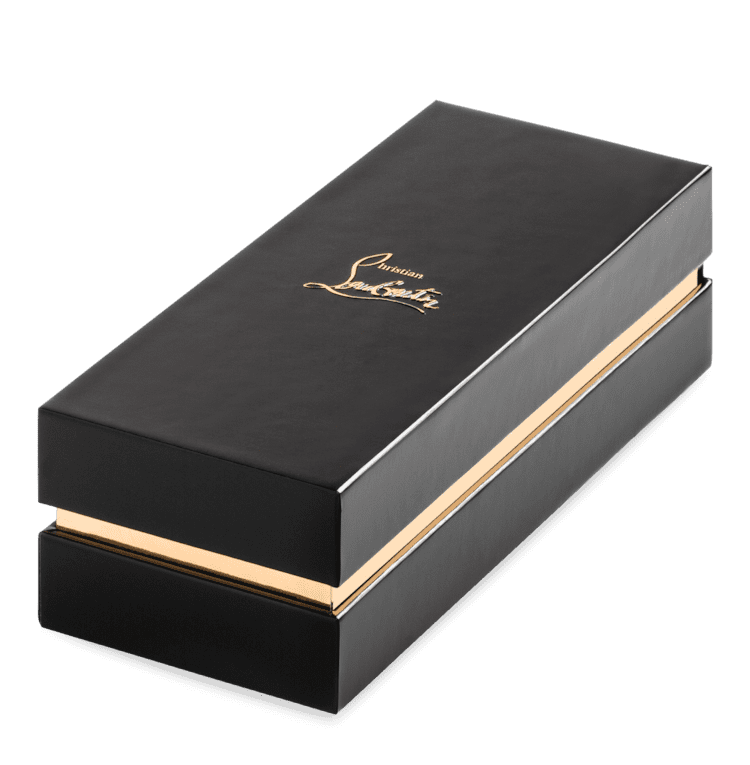

- Metallic ink: Metallic ink is a single-color printing technique that uses metallic ink to create a shiny, reflective image. This is a great option for packaging designs that want to create a luxurious or premium feel.

- Fluorescent ink: Fluorescent ink is a single-color printing technique that uses bright, neon colors. This is a great option for packaging designs that want to create a bold and eye-catching design.

What is Multi-Color Print?

Multi-color printing, also known as process printing or CMYK printing, is a printing method that uses a combination of four colors – cyan, magenta, yellow, and black – to create the design or image on packaging. This technique has several advantages and disadvantages.

Advantages of Multi-Color Printing

- Design flexibility: Multiple colors offers more design options and flexibility, allowing for a greater range of color options. This makes it a great option for brands that want to create a visually stunning packaging design.

- High detail: Multi-color printing is well suited for detailed designs or images since it can create a wide range of hues and shades. This makes it a great option for packaging designs that want to convey a lot of information or create an intricate design.

- Contrast: With multiple colors, it is easier to create contrast between different elements of the design. This can make the packaging design look more interesting and dynamic.

Disadvantages of Multi-Color Printing

- Costly: Multi-color printing is more expensive than single-color printing since it requires four ink colors and printing plates, or it can be digital printed which is a more expensive method. This makes it a less cost-effective option for brands that have a tight budget.

- Inconsistent color: Maintaining consistency in color throughout the entire print run can be challenging with multi-color printing. This is because slight variations in ink density or printing conditions can affect the color of the final print, unless it is printed as PMS color, which will be costlier.

- Complex setup: The setup process for multi-color printing is more complex than single-color printing, requiring four separate printing plates. This can make the printing process more time-consuming and expensive.

Examples of Multi-Color Printing

- Full-color printing: Full-color printing is a popular example of multi-color printing. It is a great option for packaging designs that want to create a vibrant and eye-catching design.

- Gradient printing: Gradient printing is a multi-color printing technique that uses a range of hues and shades to create a smooth transition between colors. This is a great option for packaging designs that want to create a subtle or sophisticated design.

- Spot color printing: Spot color printing is a multi-color printing technique that uses a few specific colors to create a design. This is a great option for packaging designs that want to create a specific color scheme or highlight certain elements of the design.

Summary: Single-Color vs Multi-Color Print

In conclusion, the choice between single-color and multi-color printing in packaging design depends on the design needs and budget of the project. Single-color printing is a cost-effective option that provides vibrant and consistent color, but it has limited design options. Multi-color printing offers more design flexibility and detail, but it can be more expensive and challenging to maintain consistency in color throughout the print run. Ultimately, it is up to the designer and the brand to determine which method is best suited for their packaging needs.

If you are interested in custom printed packaging solutions, then contact Brown Packaging to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » Single-Color vs. Multi-Color Printing in Packaging: Pros and Cons

Packaging is an essential aspect of any product’s marketing strategy. It is often the first point of contact with the consumer and can greatly influence

In the competitive pet care industry, packaging graphics can be as influential as product quality when it comes to driving sales. For pet food, treats,

Packaging labels and graphics serve as the face of a product, making them an integral part of brand identity and consumer appeal. However, the longevity