Home » Should Your Packaging Have Interior Print? Factors to Consider and Print Options Explained

Should Your Packaging Have Interior Print? Factors to Consider and Print Options Explained

Packaging plays a crucial role in attracting customers and promoting brand recognition. Companies often spend a lot of time and money designing the perfect package for their products, and one element that can add a unique touch is interior printing.

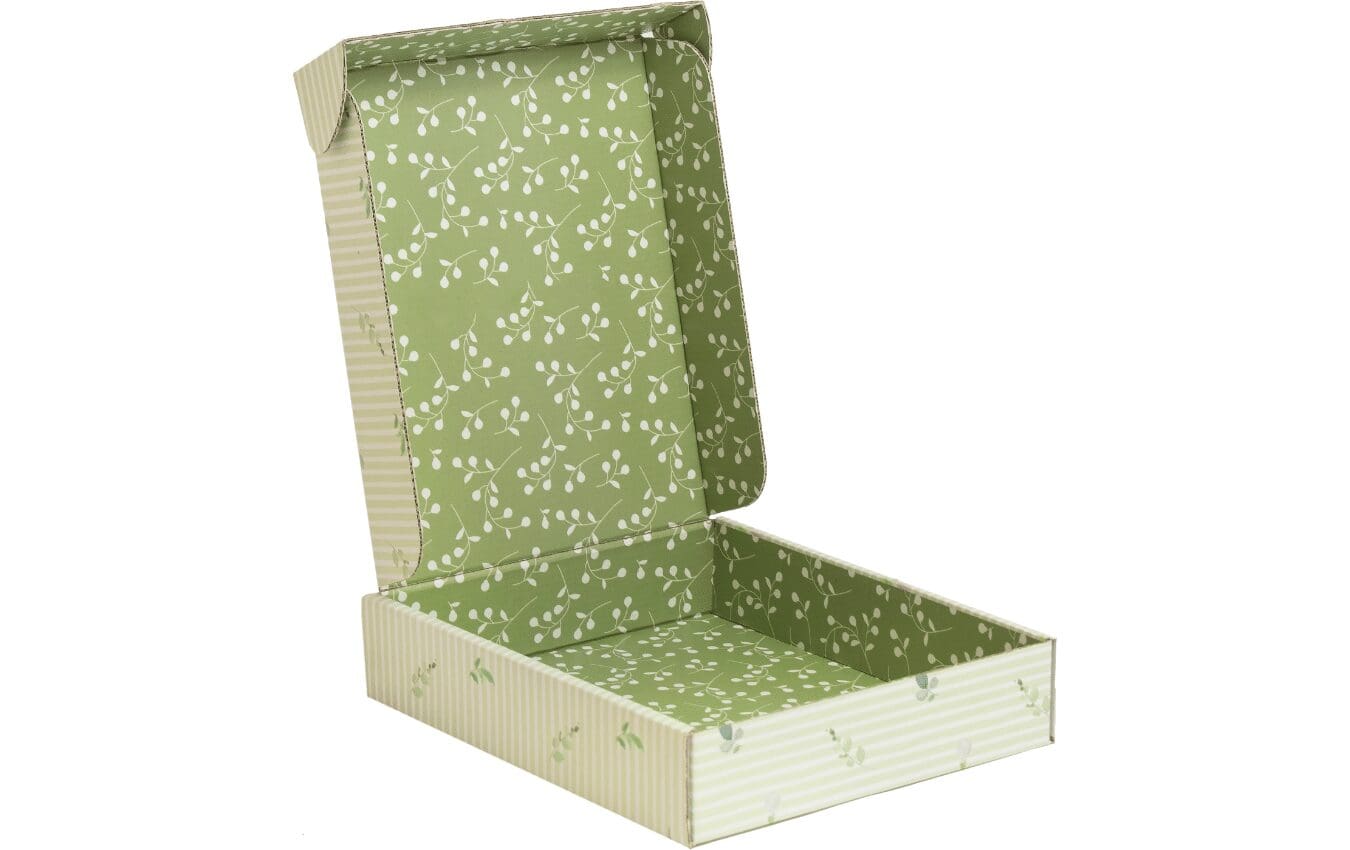

Interior printing involves printing graphics or text on the inside of a package, such as a box or a bag. This can add an extra level of detail and visual interest to the packaging, but it’s important to consider whether or not it’s the right choice for your product.

Why You Should Consider Interior Print

In this blog, we’ll explore the factors to consider when deciding whether or not your packaging should have interior print.

The Nature of Your Product

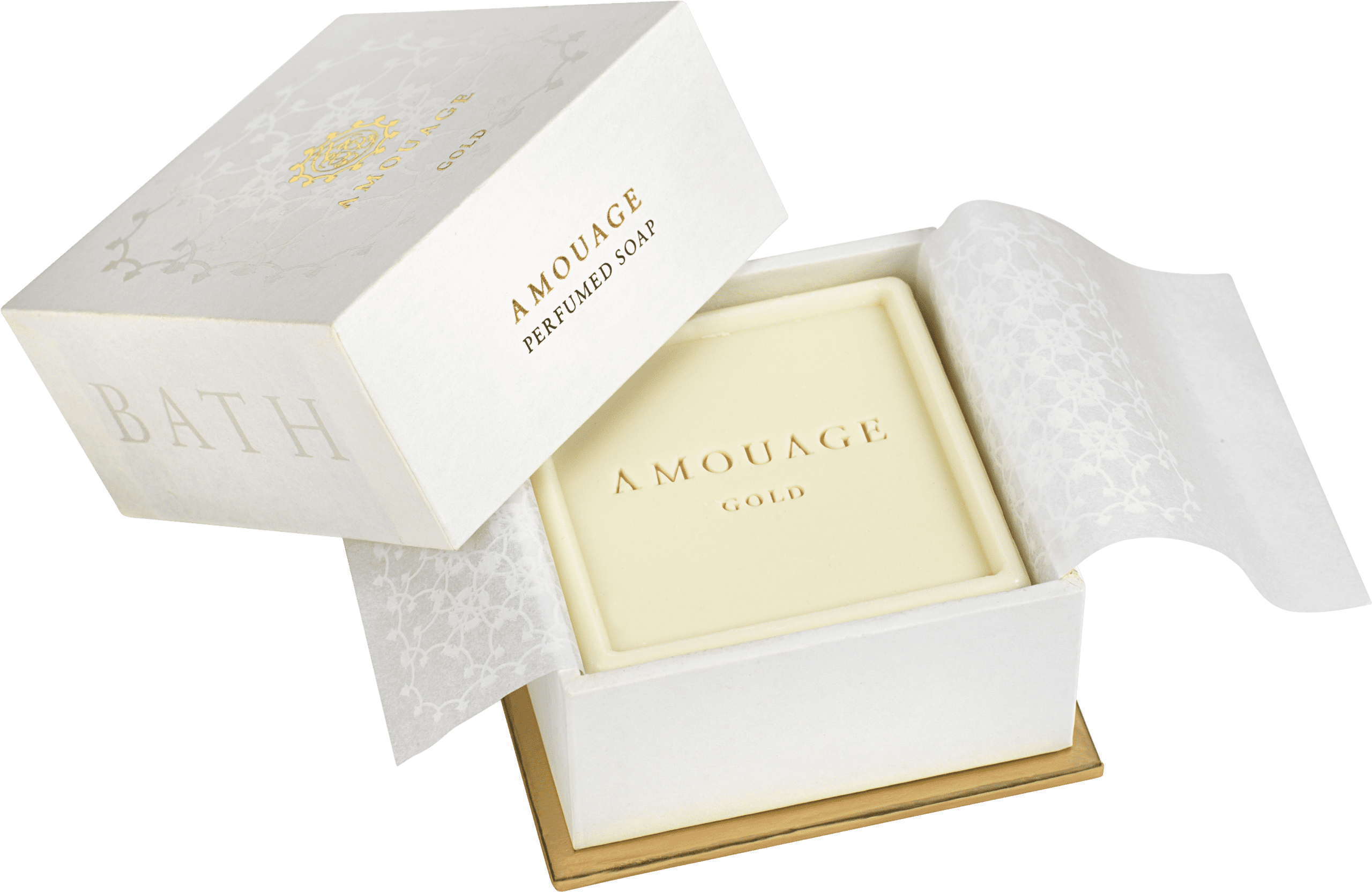

The first factor to consider is the nature of your product. Is it a luxury item that requires high-end packaging? Is it a product that requires a lot of information on the packaging, such as instructions or ingredients? If your product is high-end or requires a lot of information, interior printing can be a great way to add an extra layer of detail without sacrificing space on the exterior of the packaging.

The Target Audience

Consider the target audience for your product. Will they appreciate the extra effort put into the packaging, or will they not notice or care? If your target audience is a group that values luxury or high-end products, they may be more likely to appreciate interior printing. On the other hand, if your product is targeted towards a budget-conscious consumer, they may not value the added expense of interior printing.

The Budget

Interior printing can be more expensive than regular packaging, so it’s important to consider your budget. Can you afford the extra cost of interior printing, or would that money be better spent on other aspects of the product or marketing? Consider the return on investment of interior printing and whether or not it will have a significant impact on sales.

The Design of the Packaging

The design of the packaging should also be taken into account when deciding whether or not to include interior printing. If the exterior design is busy or already includes a lot of graphics and text, interior printing may not be necessary and could make the packaging feel cluttered. On the other hand, if the exterior design is simple, interior printing can add an extra level of interest and detail.

The Packaging Material

Finally, consider the material of the packaging. Some materials, such as paper or cardboard, are easier to print on the interior than others. If the packaging material is not conducive to interior printing, it may not be worth the extra expense or effort.

Popular Print Options Available for Interior Packaging Print

There are several print options available for applying graphics and text to the inside of packaging. These include digital printing, lithographic printing, flexographic printing, and screen printing. Each option has its own unique features, advantages, and limitations. Below are brief explanations of each option:

Digital Printing

Digital printing is a relatively new printing process that uses digital files to produce high-quality prints. It is a popular option for printing on the inside of packaging because it can produce crisp, vibrant images and text with minimal setup time. Digital printing is also highly customizable, allowing for unique designs that can be changed quickly and easily. One drawback of digital printing is that it is not ideal for high-volume printing due to cost.

Lithographic Printing

Lithographic printing, also known as offset printing, is a popular option for high-volume printing jobs. It involves transferring ink from a plate onto a rubber blanket and then onto the packaging material. Lithographic printing produces high-quality prints with sharp details and vibrant colors. However, it requires a significant setup time and is not as customizable as digital printing.

Flexographic Printing

Flexographic printing is a popular option for printing on flexible packaging materials such as plastic bags and films. It uses flexible rubber plates to transfer ink onto the packaging material. Flexographic printing can produce high-quality prints at high speeds, making it ideal for high-volume printing jobs. However, it is not as precise as other printing methods and may produce slightly blurred or distorted images.

Screen Printing

Screen printing involves creating a stencil or mesh screen of the desired design and then transferring ink through the screen onto the packaging material. Screen printing can produce high-quality prints with vibrant colors and can be used on a variety of materials, including paper, plastic, and fabric. However, it is not as efficient as other printing methods and requires a significant amount of setup time.

Summary: Interior Packaging Print

In conclusion, the decision to use interior printing on packaging requires careful consideration of several factors, including the product, target audience, budget, packaging design, and material. Interior printing can enhance the customer experience and create a memorable impression, but it should be used strategically and in line with the brand identity.

By selecting the appropriate print option, businesses can create stunning and unique packaging designs that not only protect their products but also increase brand recognition and customer loyalty.

If you are interested in custom printed packaging, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Should Your Packaging Have Interior Print? Factors to Consider and Print Options Explained

Rigid boxes are known for their premium feel, durability, and high-end presentation, making them the go-to choice for luxury goods, cosmetics, electronics, and gift packaging.

Printed boxes are an excellent choice for enhancing brand visibility and creating a memorable unboxing experience for customers. However, a common concern is whether they

In the world of packaging, making a memorable impression is crucial. Packaging not only protects and delivers products but also serves as a powerful branding