Home » RSC vs. Specialty Boxes

RSC vs. Specialty Boxes

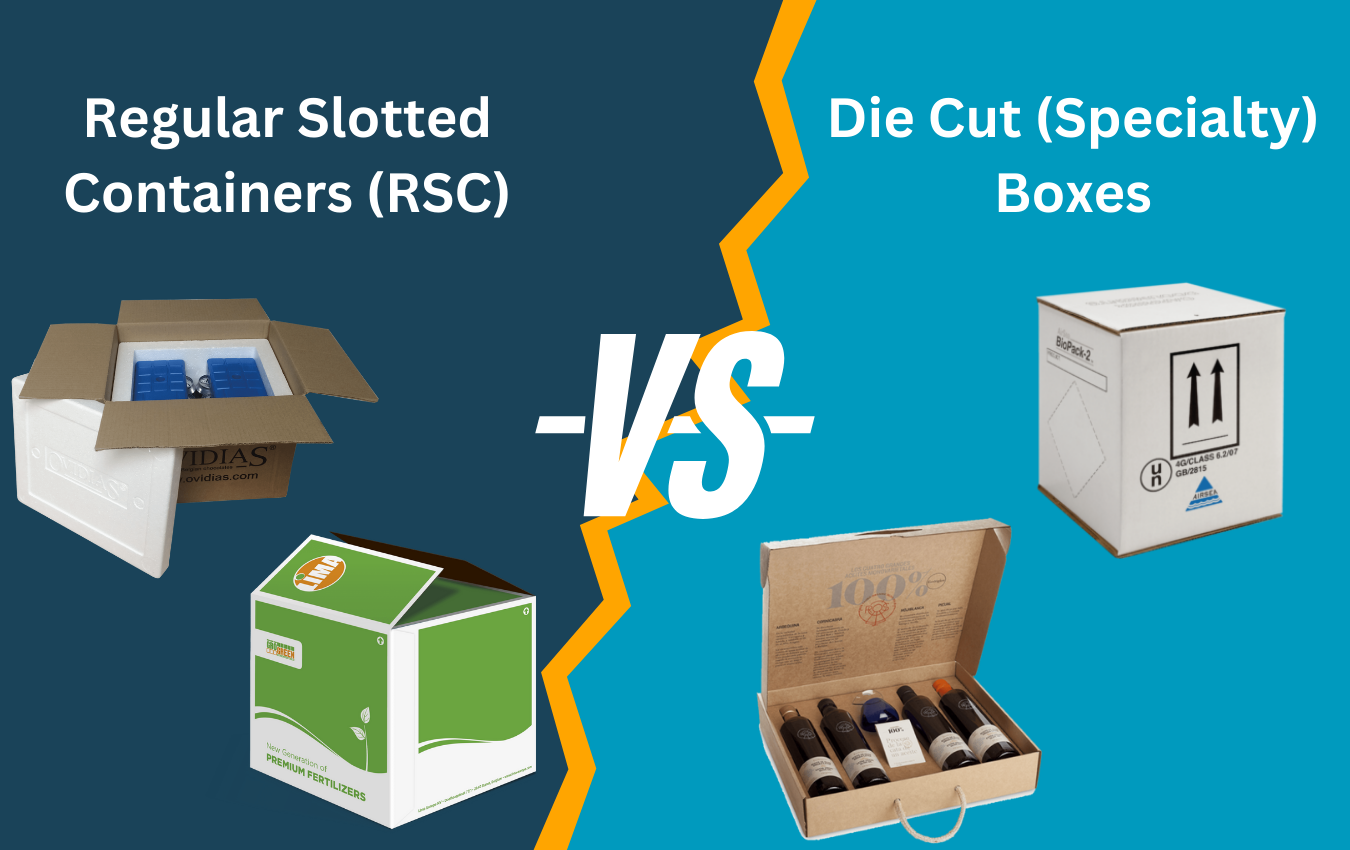

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer unique advantages for certain applications. Understanding when to stay with an RSC versus upgrading to a specialty style ensures buyers balance cost, performance, and presentation.

When RSC Is Best

- Bulk Shipping: Strong compression strength makes RSC ideal for palletized loads.

- Low Cost: Efficient to manufacture with minimal board waste.

- Versatility: Works across industries from industrial to retail.

- Automation-Ready: Standardized design runs smoothly on case erectors and palletizers.

When Specialty Boxes Are Better

Full Overlap (FOL)

- Flaps overlap fully, reinforcing the top and bottom.

- Better for heavy products or shipments that need extra stacking strength.

RETT Mailers

- Dust flaps and cherry locks eliminate tape, improving assembly speed.

- Ideal for e-commerce and branded unboxing experiences.

Die-Cut Boxes

- Custom shapes and closures for product-specific fit.

- Useful when presentation and consumer experience are top priorities.

Key Trade-Offs

Feature | RSC Box | Specialty Box Styles |

Assembly Speed | Slower (tape required) | Faster (die-cut, self-locking) |

Stacking Strength | High | Variable (higher in FOL, lower in mailers) |

Branding Potential | Basic | Premium (better graphics and unboxing) |

Flexibility | Universal | Application-specific |

Buyer Takeaway

- Stick with RSC when cost, strength, and scalability matter most.

- Upgrade to FOL for heavy-duty industrial shipments.

- Choose RETT or die-cut mailers for e-commerce and premium branding.

By evaluating your priorities — strength, speed or presentation — you can decide whether RSC remains the best fit or if specialty box styles deliver added value.

References

- Fibre Box Association. (2023). Corrugated Box Styles and Applications. https://www.fibrebox.org

- Association of Independent Corrugated Converters (AICC). (2024). Corrugated Design and Performance. https://www.aiccbox.org

- Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » RSC vs. Specialty Boxes