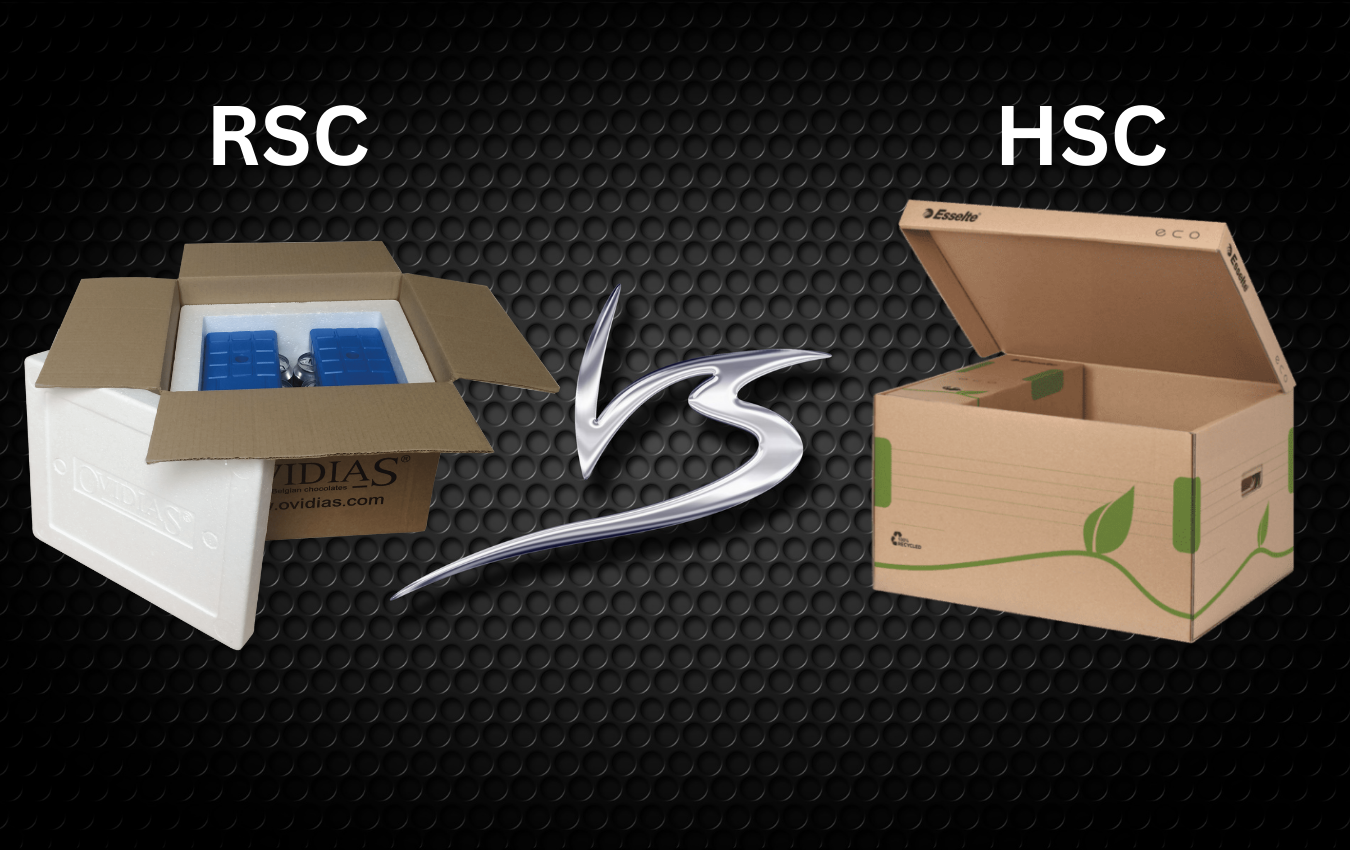

Home » RSC Vs HSC Boxes: Compared and Contrast

RSC Vs HSC Boxes: Compared and Contrast

Packaging is an essential component of product marketing, as it not only protects the products but also helps in promoting them. Boxes are the most common type of packaging material used by businesses of all sizes, and there are several types of boxes available in the market, including regular slotted containers (RSC) and half slotted containers (HSC).

Quick Overview: RSC Vs HSC Boxes

In this blog, we will compare and contrast RSC and HSC boxes in order to help you select the right one for your business needs.

- Definitions

- Customization Options

- Features

- Benefits

- Advantages

- Applications

- How to Select the Right Box for Your Business Needs

We will also provide guidance on how a packaging buyer can select the appropriate type of box for their business needs.

Definitions

Regular slotted containers (RSC) are the most common type of box used in packaging. They are made from a single sheet of corrugated cardboard that is cut and scored to create four flaps at the top and bottom of the box. The flaps are then folded and sealed with tape to form the box. RSC boxes are versatile and can be used for a variety of products.

Half slotted containers (HSC) are similar to RSC boxes but only have one set of flaps, which are located at the top of the box. The bottom of the box is left open, which makes it ideal for larger products or products that require loading from the top. HSC boxes are also versatile and can be used for a variety of products.

Customization Options

Both RSC and HSC boxes can be customized to meet specific business needs. Businesses can choose the size, shape, and thickness of the cardboard used to create the boxes. They can also choose to print logos, product information, and other graphics on the boxes to enhance their branding.

Features

RSC boxes are designed to be sturdy and secure, with four flaps that provide extra protection for the product inside. They can be stacked on top of each other without collapsing, which makes them ideal for shipping and storage.

HSC boxes, on the other hand, are designed to be open at the bottom, which makes them easier to load and unload. They are also lighter than RSC boxes, which makes them more cost-effective to ship.

Benefits

RSC boxes are versatile and can be used for a variety of products. They are also strong and durable, which makes them ideal for shipping and storage. They are also cost-effective and can be easily stacked, which saves space and reduces transportation costs.

HSC boxes are ideal for larger products or products that require loading from the top. They are also lightweight and cost-effective to ship. They are also easier to load and unload, which saves time and reduces labor costs.

Disadvantages

RSC boxes are not as easy to load and unload as HSC boxes, which can increase labor costs. They are also not suitable for products that require loading from the top.

HSC boxes are not as secure as RSC boxes, as they only have one set of flaps at the top. This can make them less suitable for products that require extra protection during shipping and storage.

Applications

RSC boxes are ideal for a variety of products, including electronics, food and beverage products, and household items. They are also commonly used in the e-commerce industry, as they are cost-effective and easy to stack.

HSC boxes are ideal for larger products, such as appliances, furniture, and industrial equipment. They are also commonly used in the agriculture industry, as they are lightweight and easy to load and unload.

How to Select the Right Box for Your Business Needs

When selecting the appropriate type of box for your business needs, there are several factors to consider. These include:

- Product Size and Weight: If you are shipping large or heavy products, an HSC box may be more suitable, as it provides easy access for loading and unloading. However, if your product is smaller and requires more protection, an RSC box may be the better option.

- Protection Needs: If your product requires extra protection during shipping and storage, an RSC box may be more suitable, as it has four flaps that provide extra protection. However, if your product is less fragile, an HSC box may be a more cost-effective option.

- Shipping and Storage Needs: If you are shipping or storing products in large quantities, an RSC box may be more suitable, as it is stackable and saves space. However, if you have limited storage space or are shipping smaller quantities, an HSC box may be more suitable.

- Budget: Both RSC and HSC boxes are cost-effective options for packaging, but the price may vary depending on the size and customization options chosen. Consider your budget when selecting the appropriate type of box for your business needs.

Summary: RSC Vs HSC Boxes

In conclusion, both regular slotted containers (RSC) and half slotted containers (HSC) have their own unique features, benefits, and disadvantages. When selecting the appropriate type of box for your business needs, consider factors such as product size and weight, protection needs, shipping and storage needs, and budget.

If you are interested in corrugated boxes such as RSC, HSC or alternatives, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » RSC Vs HSC Boxes: Compared and Contrast

When choosing corrugated packaging, box style directly impacts cost, strength, speed of packing, and customer experience. Two of the most common options are the Regular

Corrugated boxes are a staple in the packaging world, known for their strength and versatility. However, maximizing their durability is key to ensuring products reach

In the ever-evolving world of packaging, finding the perfect combination of features that ensures both security and ease of use can be a challenging endeavor.