Home » RSC Box Design Fundamentals: Why It’s the Industry Standard

RSC Box Design Fundamentals: Why It’s the Industry Standard

The Regular Slotted Container (RSC) is the most widely used corrugated box style in the world. Its simplicity, manufacturing efficiency, and versatility make it the default choice across industries ranging from industrial parts to e-commerce fulfillment. Understanding what makes RSC boxes so effective helps buyers decide when standardization is the best approach — and when alternatives may be worth considering.

What Defines an RSC Box

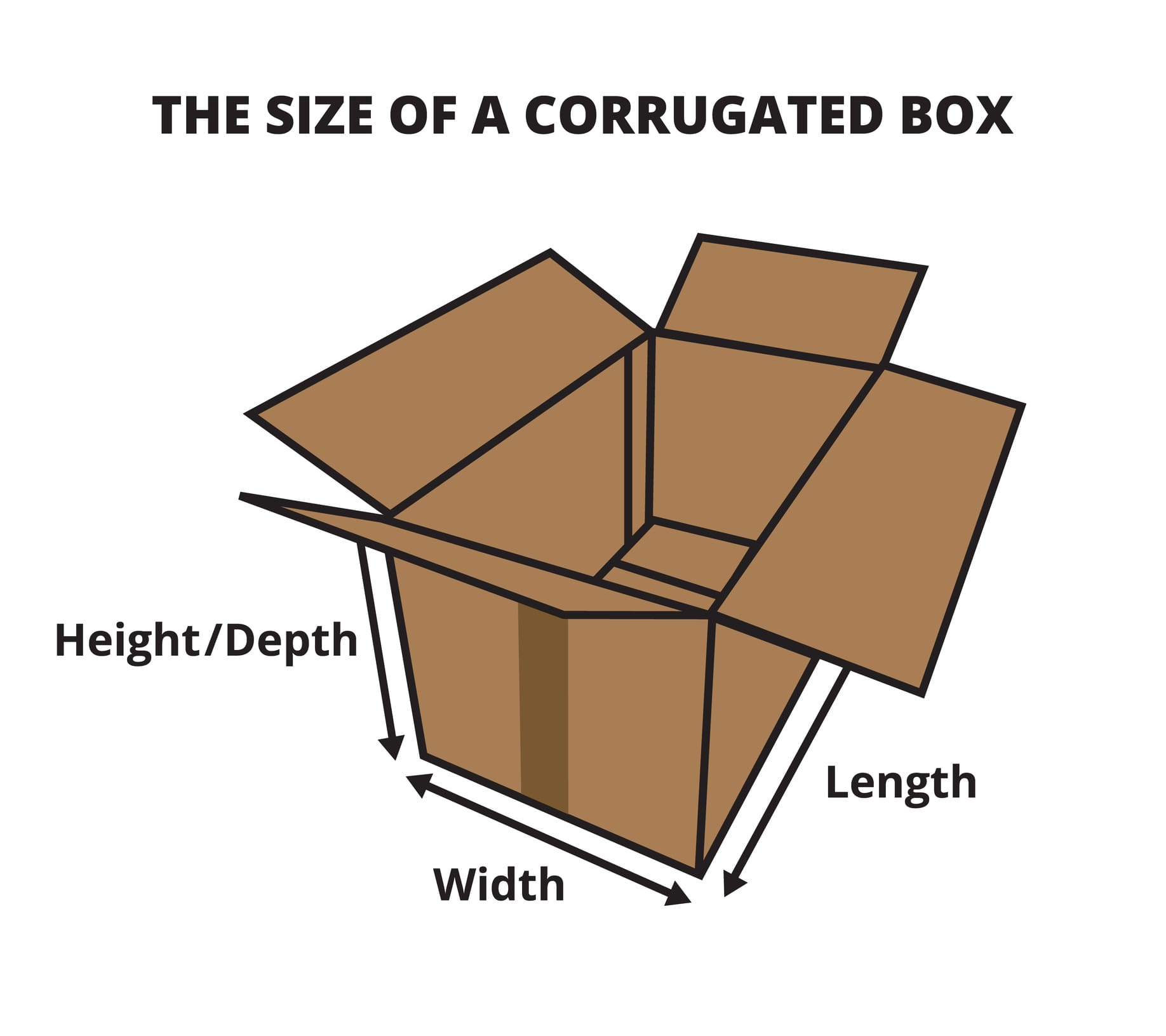

An RSC is manufactured from a single sheet of corrugated board with flaps of equal length that meet at the center when folded. The design minimizes board waste, requires only a single die-cut or slotting process, and can be assembled with tape, glue, or staples. Its dimensions can be adjusted easily to accommodate nearly any product size.

Why RSC Remains the Standard

Manufacturing Efficiency

- RSCs use minimal board compared to other box styles.

- They can be produced on high-speed corrugators and folder-gluers without complex tooling.

- Standardized sizes reduce lead times and lower setup costs.

Structural Strength

- The design maximizes stacking strength with flaps that reinforce the edges of the container.

- Compatible with a wide range of flute profiles and board grades, from single-wall E-flute to triple-wall heavy-duty.

Versatility

- Works for products ranging from lightweight consumer goods to heavy industrial components.

- Compatible with automation in packing, sealing, and palletization systems.

- Easily branded with flexographic or digital print for retail and e-commerce applications.

Cost Effectiveness

- Board utilization is highly efficient, reducing waste.

- Standardized production reduces cost per unit at scale.

- Assembly and sealing are simple, requiring minimal labor and materials.

Limitations of the RSC

While RSC is unmatched for general-purpose shipping, it’s not always the best option:

- Requires tape, glue, or staples, which adds materials and labor.

- Lacks the premium presentation of die-cut mailers for e-commerce.

For unusually heavy or fragile products, other styles (like Full Overlap or RETT) may provide better performance.

Buyer Takeaway

RSC boxes dominate corrugated packaging for one reason: they offer the best balance of strength, efficiency, and cost. If your priorities are bulk shipping, pallet strength, and scalability, RSC is almost always the right choice. But for premium presentation, automation-friendly features, or specialty protection, it’s worth exploring alternative styles.

References

- Fibre Box Association. (2023). Corrugated Box Styles and Design Guide. https://www.fibrebox.org

- Association of Independent Corrugated Converters (AICC). (2024). Corrugated Packaging Fundamentals. https://www.aiccbox.org

- Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » RSC Box Design Fundamentals: Why It’s the Industry Standard