Home » Regular Slotted Containers (RSC) Explained: Applications & Alternatives

Regular Slotted Containers (RSC) Explained: Applications & Alternatives

Regular Slotted Containers (RSC) are the most widely used corrugated boxes in packaging. Their standardized design, strength options, and cost efficiency make them suitable for shipping, storage, and retail applications across industries.

Design and Structure

RSC boxes feature four flaps of equal length, with the two longest meeting at the center when closed. This simple structure provides efficient use of corrugated board while maintaining durability. Internal measurements follow the sequence: length (L) × width (W) × height (H).

Applications of RSC Boxes

Shipping and distribution: Lightweight, stackable, and cost-effective.

Storage: Easy to seal and palletize for warehouse environments.

Ecommerce: Provides reliable protection for direct-to-consumer shipments.

Retail packaging: Can be printed with branding for shelf display.

Material Strength Options

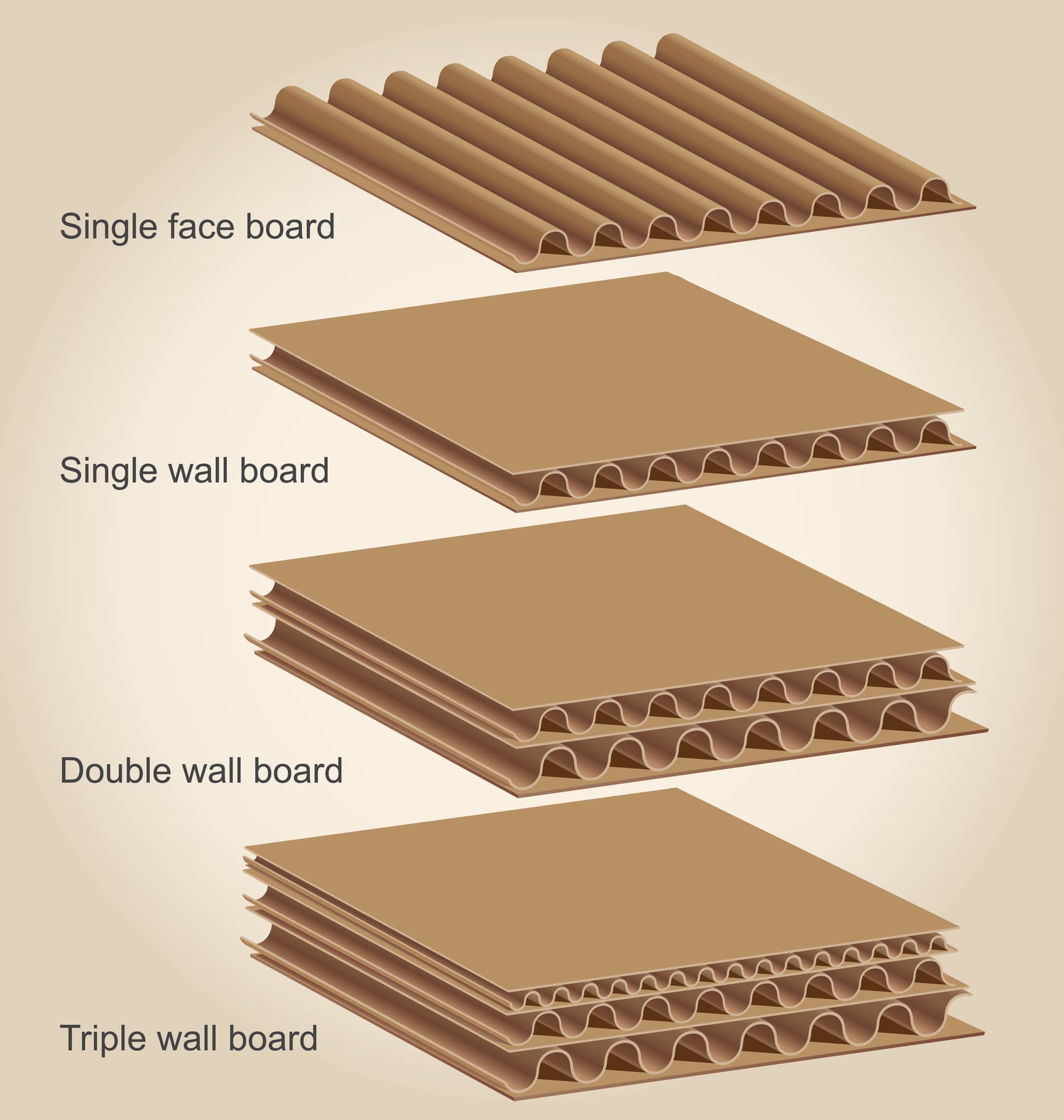

Corrugated board is available in multiple flute profiles (e.g., B, C, E) and strength grades (single-wall, double-wall, triple-wall). This allows RSC boxes to handle a wide range of load requirements, from lightweight goods to heavy industrial parts.

Advantages of RSC

High versatility across industries.

Efficient use of corrugated material.

Compatible with automation for sealing and palletizing.

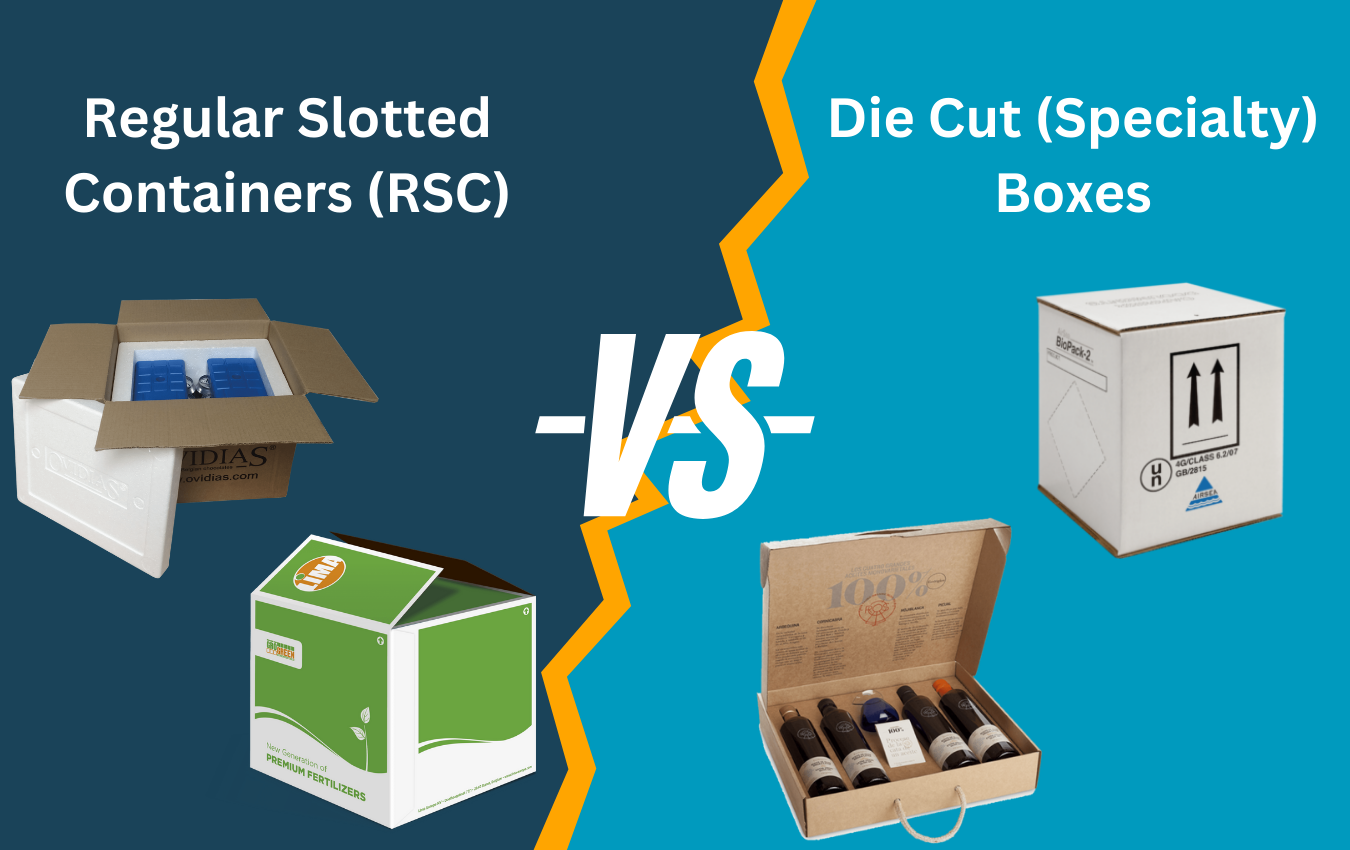

Cost-effective compared to custom die-cut boxes.

Limitations of RSC

While versatile, RSC boxes may not be ideal for every application. For fragile, high-value, or irregularly shaped items, alternatives like die-cut cartons, full overlap containers (FOL), or five-panel wraps can provide better protection and presentation.

Explore RSC Solutions

Brown Packaging specializes in custom corrugated solutions, from standard RSC boxes to complex designs tailored to your supply chain. Contact us to learn how RSC can fit into your packaging strategy.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

Fiber Box Association. (2022). Corrugated Packaging 101. Retrieved from https://www.fibrebox.org

FSC. (2023). Chain of Custody Certification. Forest Stewardship Council.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Regular Slotted Containers (RSC) Explained: Applications & Alternatives

When it comes to packaging, boxes made from a material called corrugated board are among the most commonly used types today. Corrugated board consists of

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer

In the ever-evolving world of packaging, finding the perfect combination of features that ensures both security and ease of use can be a challenging endeavor.