Home » Plastic vs Paper Packaging Tape: Which to use?

Plastic vs Paper Packaging Tape: Which to use?

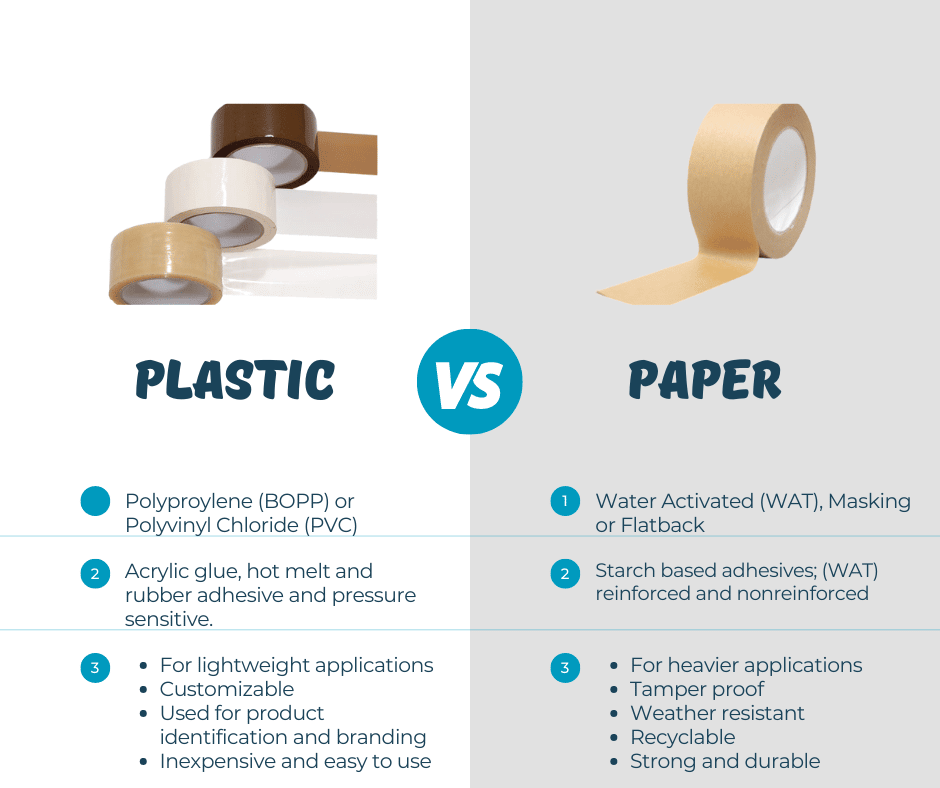

Plastic and paper packaging tapes both serve the same core purpose — sealing, wrapping, and bundling packages — but their performance differs depending on application. Each has unique properties that affect strength, cost, recyclability, and security. Choosing the right tape ensures your packaging remains efficient, secure, and cost-effective.

Plastic Packaging Tape

Plastic tape, often called clear tape, is a pressure-sensitive tape designed for lightweight and general-purpose packaging. It is popular for being durable, dust-resistant, inexpensive, and easy to apply with hand or machine dispensers.

Common Types

Polypropylene (BOPP): Thin, cost-effective, customizable; best for light to medium-duty use.

Polyvinyl Chloride (PVC): Thicker, quieter, and more durable; better for heavier packages but more expensive.

Adhesives Used

Acrylic: Performs in hot and cold environments; good for long-term storage.

Hot Melt: Aggressive initial tack; best for shipping and storage but less reliable under temperature extremes.

Rubber-Based: Premium adhesive with strong bonds in all conditions; higher cost.

Advantages

Readily available and inexpensive

Easy to apply, even on the go

Highly customizable for branding

Disadvantages

Less secure than paper tape

Often requires multiple layers for strength

Lower recyclability compared to paper tape

Best Applications

Plastic tape is best for lightweight, everyday shipping and situations where cost efficiency and branding flexibility matter.

BOPP Tape

PVC Tape

Paper Packaging Tape

Paper tape, often called Kraft tape, uses a starch-based adhesive and is valued for its strength, tamper resistance, and sustainability. It is ideal for heavy-duty or high-security packaging.

Common Types

Water Activated Tape (WAT): Creates a permanent bond when moistened. Available in reinforced (fiberglass strands) or non-reinforced grades.

Flatback Tape: Pressure-sensitive version suitable for heavy packaging and weather-resistant sealing. Available in multiple colors.

Advantages

Strong and tamper-proof

Requires less tape per seal

Recyclable and eco-friendly

Performs well in extreme environments

Disadvantages

Requires a dispenser (less portable)

Slower to apply in fast-paced operations

Best Applications

Paper tape is best for heavier, high-value shipments where strength, security, and sustainability are priorities. Common in food, pharmaceuticals, healthcare, electronics, and e-commerce.

Water Activated Tape

Flatback Tape

Plastic vs. Paper: Key Differences

| Feature | Plastic Tape | Paper Tape |

|---|---|---|

| Material | Polypropylene or PVC | Kraft paper with starch adhesive |

| Application | Lightweight, general use | Heavy-duty, tamper-proof |

| Ease of Use | Portable, quick to apply | Requires dispenser |

| Sustainability | Less recyclable | Fully recyclable |

| Security | Lower | Higher (tamper evident) |

| Cost | Lower upfront cost | Higher upfront, less used per seal |

Work With Brown Packaging

At Brown Packaging, we help businesses select the right tape for their specific shipping and operational needs. Whether you need cost-effective plastic tape for high-volume shipments or secure paper tape for heavy-duty applications, our team can guide you toward the best choice. Contact Brown Packaging today to get started.

References

Pressure Sensitive Tape Council (PSTC). (2023). Packaging Tape Standards and Applications. Retrieved from https://www.pstc.org

Flexible Packaging Association. (2023). Adhesives and Packaging Performance. Retrieved from https://www.flexpack.org

Robertson, G. L. (2016). Food Packaging: Principles and Practice (3rd ed.). CRC Press.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Plastic vs Paper Packaging Tape: Which to use?

Holiday e-commerce packaging carries two expectations: delivering a memorable unboxing experience and meeting sustainability standards. Shoppers want festive branding, but they also expect recyclability and

In today’s highly competitive marketplace, the packaging of a product plays a crucial role in determining a brand’s success. It is the first point of

Contract packaging, also known as co-packing or third-party packaging, is a service where a company outsources the packaging of their products to a specialized provider.