Home » Physical vs Digital Packaging Prototypes: Choosing the Right Prototype for Your Business Needs

Physical vs Digital Packaging Prototypes: Choosing the Right Prototype for Your Business Needs

In today’s market, packaging plays a crucial role in product sales and branding. It is one of the most critical aspects of a product’s marketing strategy, making it essential for businesses to get it right. There are two main types of packaging prototypes: physical and digital. Each has its benefits and drawbacks, and understanding these differences can help businesses choose the right prototype for their packaging needs.

Physical Packaging Prototypes

Physical prototypes are tangible models of a product’s packaging. These prototypes are made using physical materials like cardboard, plastic, and metal. The prototype is a full-scale representation of the final packaging design, giving businesses a realistic idea of how the packaging will look and feel.

Benefits of Physical Packaging Prototypes

- Realistic Experience: Physical prototypes offer a tactile experience that digital prototypes cannot replicate. The user can touch, feel, and interact with the packaging, giving a more realistic experience.

- Accurate Color Representation: Color representation is an essential aspect of packaging design. Physical prototypes offer a more accurate color representation than digital prototypes, as colors can appear differently on screens than they do in real life.

- Detailed Design: Physical prototypes offer businesses the opportunity to see and test the detailed design of the packaging, including the structure, materials, and finish.

- Easy to Understand: Physical prototypes are easier for everyone to understand, even those who may not be familiar with design software.

Drawbacks of Physical Packaging Prototypes

- Time-consuming: Physical prototypes can be time-consuming to create and may require multiple iterations before the final design is achieved.

- Costly: Creating physical prototypes can be expensive, especially if multiple iterations are required.

- Limited Revisions: Making changes to a physical prototype can be challenging and may require starting from scratch, which can be costly and time-consuming.

Digital Packaging Prototypes

Digital packaging prototypes are created using software and computer graphics. They are virtual representations of the final packaging design, giving businesses a 3D view of the packaging design.

Benefits of Digital Packaging Prototypes

- Quick and Cost-effective: Digital prototypes are quick and cost-effective to create compared to physical prototypes.

- Easy Revisions: Making changes to a digital prototype is easy and cost-effective. It can be done quickly without the need for starting from scratch.

- Eco-friendly: Digital prototypes are environmentally friendly, as they do not require physical materials, reducing waste.

- Easy Collaboration: Digital prototypes can be shared electronically, making it easy to collaborate with remote team members.

Drawbacks of Digital Packaging Prototypes

- Lack of Tactile Experience: Digital prototypes lack a tactile experience, making it difficult to understand how the packaging will feel in real life.

- Limited Color Representation: Colors can appear differently on screens than they do in real life, leading to inaccurate color representation.

- Limited Detail: Digital prototypes may not show the finer details of the packaging, including the texture and finish.

- Steep Learning Curve: Creating digital prototypes can have a steep learning curve, requiring specialized software and technical skills.

Summary: Physical Vs Digital Packaging Prototypes

Both physical and digital packaging prototypes have their benefits and drawbacks. Physical prototypes offer a realistic experience, accurate color representation, and detailed design, but they can be time-consuming and costly. Digital prototypes, on the other hand, are quick and cost-effective, easy to revise, eco-friendly, and offer easy collaboration, but they lack a tactile experience and may have limited detail and color representation.

If you are interested in custom packaging solutions, then partner with Brown Packaging today.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » Physical vs Digital Packaging Prototypes: Choosing the Right Prototype for Your Business Needs

Corrugated boxes are a packaging mainstay, known for their durability, affordability, and eco-friendliness. Yet, when it comes to securing delicate or valuable items during transit,

Today, more and more brands are switching to sustainable packaging options to improve their social responsibility to the environment and to meet any regulation or

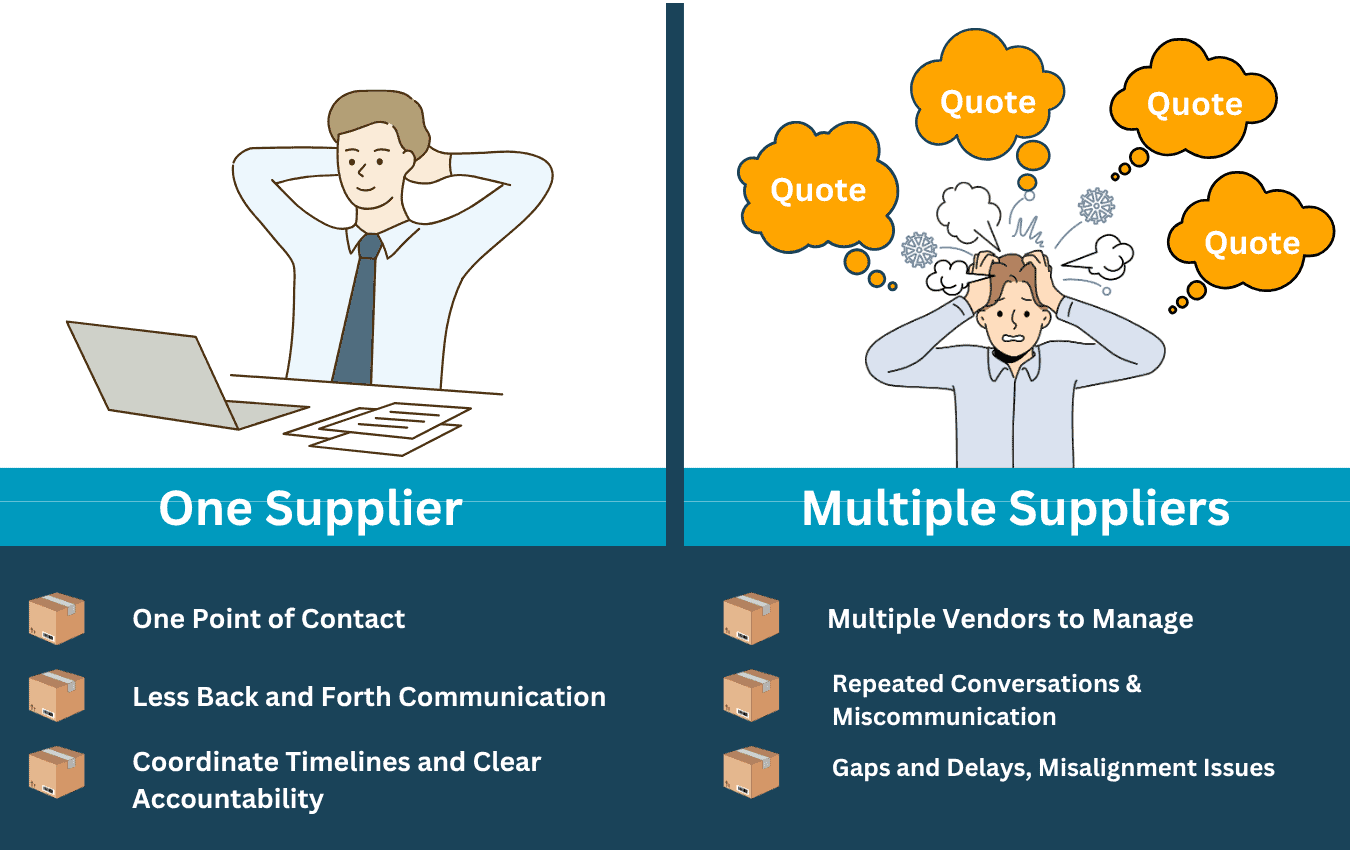

Managing packaging for your business is more than just ordering boxes and labels—it’s about sourcing the right materials, coordinating timelines, ensuring quality, and staying aligned