Home » Pet Product Packaging That Withstands E-Commerce Handling

Pet Product Packaging That Withstands E-Commerce Handling

E-commerce packaging for pet products must endure far more stress than traditional retail packaging. Shipments face repeated drops, vibration, compression, and environmental fluctuations. Structural design, material selection, and protective features must work together to ensure the product arrives in perfect condition.

Key Hazards in E-Commerce Distribution

- Drop Impact: Packages may be dropped from heights of up to 1.2 m (4 ft) during sortation or delivery.

- Vibration: Continuous shaking in transit can cause product settling or material fatigue.

- Compression: Stacking in transit or warehouses can deform or crush underfilled packages.

- Moisture and Temperature Extremes: Exposure to rain, snow, and heat during delivery.

Structural Design Considerations

- Reinforced Corrugated Shippers: Double-wall or heavy-duty C-flute for bulk pet food and accessories.

- Internal Bracing or Partitioning: Keeps products from shifting during transit.

- Right-Sizing: Minimizes void space to reduce product movement and dimensional weight charges.

Material Selection

- Moisture-Resistant Coatings: For corrugated and paperboard used in outer shipping containers.

- Puncture-Resistant Films: Prevent tearing from sharp pet accessories like toys or grooming tools.

- Impact-Absorbing Cushioning: Paper-based or foam inserts to protect fragile items such as glass supplement jars.

Protective Features

- Tamper-Evident Seals: Maintain consumer trust and ensure product integrity.

- Overwraps or Polybags: Provide secondary protection against moisture and dirt.

- Label Durability: Smudge- and water-resistant labels for scannability.

Performance Testing for E-Commerce

- Drop Testing: ISTA 3A or ASTM D5276 to simulate parcel handling.

- Vibration Testing: ASTM D999 to evaluate performance under prolonged vibration.

- Compression Testing: ASTM D642 to determine stacking strength.

- Environmental Conditioning: ASTM D4332 to simulate humidity and temperature changes.

E-Commerce Packaging Guidelines

- Amazon ISTA 6 Standards: Requires packaging to pass drop and vibration tests without damage.

- Right-Weighting: Balancing durability with material reduction to lower shipping costs.

- Consumer Experience: Easy-open designs and branding that reinforce product quality.

References

ASTM International. (2015). ASTM D5276-15: Standard test method for drop test of loaded containers by free fall. ASTM International. https://doi.org/10.1520/D5276-15

ASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://doi.org/10.1520/D0642-15

International Safe Transit Association. (2022). ISTA test procedures. https://ista.org

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Home » Pet Product Packaging That Withstands E-Commerce Handling

Digital printing has revolutionized the packaging industry in recent years. It has brought a lot of flexibility, creativity, and efficiency to the packaging process. It has enabled brands to customize their packaging designs and produce them in small quantities at a lower cost than traditional printing methods. As digital printing technology continues to improve, it is poised to have an even greater impact on the packaging industry in the future. Quick Overview: Future of Digital Print In this blog, we will explore the future of digital print in packaging. Customization and Personalization Faster Time-to-Market Sustainable Packaging Greater Efficiency and Cost-Effectiveness Advanced Printing Techniques On-Demand Printing Interactive Packaging Improved Quality Smart Packaging Greater Flexibility Customization and Personalization Digital printing has made it possible for brands to create customized packaging designs that can be tailored to specific customer needs. In the future, this trend is expected to continue with more advanced software and technology. Brands will be able to offer more personalized packaging to their customers, such as custom graphics, text, and even individualized packaging for each product. This will help companies to differentiate their products and create a more engaging customer experience. Faster Time-to-Market Digital printing has already reduced the time-to-market for packaging products, but this trend is expected to accelerate in the future. With digital printing, brands can produce packaging designs quickly and efficiently without having to go through the lengthy setup and lead times associated with traditional printing methods. As digital printing technology continues to improve, it will become even faster and more cost-effective, making it an attractive option for brands looking to bring products to market quickly. Sustainable Packaging Sustainability is a growing concern for consumers and brands alike. Digital printing can help to reduce waste and make packaging more environmentally friendly. In the future, we can expect to see more sustainable packaging options made possible by digital printing technology. For example, brands could use digital printing to produce packaging with biodegradable materials or to print on recycled paper. This will help to reduce the environmental impact of packaging and meet the demands of environmentally conscious consumers. Greater Efficiency and Cost-Effectiveness Digital printing has already improved efficiency and cost-effectiveness in the packaging industry, but the future looks even brighter. As technology continues to improve, we can expect to see even greater efficiency gains and cost savings. For example, new software and automation tools will help to streamline the printing process, reducing waste and increasing productivity. This will make digital printing an even more attractive option for brands looking to reduce costs and improve efficiency. Advanced Printing Techniques As digital printing technology continues to advance, we can expect to see new and innovative printing techniques emerge. For example, augmented reality (AR) could be used to enhance packaging designs and create a more interactive customer experience. This advanced printing technique will help brands to differentiate their products and create a more engaging customer experience. On-Demand Printing Digital printing enables brands to print packaging on-demand, which means they can produce smaller quantities of packaging as and when they need it. This eliminates the need for large print runs and reduces the amount of inventory a company needs to hold. In the future, on-demand printing is expected to become even more prevalent, allowing brands to respond quickly to changing market demands and reduce their overall costs. Interactive Packaging As technology advances, packaging is becoming more interactive. Brands are using digital printing to create packaging that incorporates augmented reality (AR), QR codes, and other interactive elements. This creates a more engaging customer experience and allows brands to provide additional product information or promotional offers. In the future, we can expect to see even more interactive packaging, with brands using digital printing to create packaging that integrates with mobile apps or other digital platforms. Improved Quality Digital printing technology has already improved the quality of packaging designs, but this trend is expected to continue in the future. As the technology improves, digital printing will be able to produce even more vibrant colors, sharper images, and finer details. This will enable brands to create more visually stunning packaging designs that stand out on store shelves and capture the attention of consumers. Smart Packaging Smart packaging is a new trend in the packaging industry that uses technology to add additional functionality to packaging. For example, smart packaging can be used to monitor the temperature of food products, track the location of shipped products, or provide real-time product information to consumers. Digital printing technology is a key component of smart packaging, allowing brands to incorporate sensors, antennas, and other electronic components into packaging designs. In the future, we can expect to see more smart packaging solutions made possible by digital printing technology. Greater Flexibility Digital printing enables brands to produce packaging designs with greater flexibility than traditional printing methods. Brands can easily make changes to packaging designs, produce smaller quantities of packaging, and create custom packaging for specific products or events. In the future, we can expect to see even greater flexibility in digital printing, with brands using the technology to create packaging that is tailored to specific customer segments or geographic regions. This will enable brands to better meet the needs of their customers and stand out in an increasingly competitive marketplace. Summary: The Future of Digital Packaging Conclusion The future of digital print in packaging looks bright. As technology continues to improve, we can expect to see more customization, faster time-to-market, greater sustainability, improved efficiency, cost-effectiveness, and advanced printing technique. Brands that embrace digital printing will be able to differentiate themselves from the competition and create a more engaging customer experience. Digital printing is the future of packaging, and it is an exciting time to be a part of this industry. If you are interested in digital printed packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform

Effective packaging can play a critical role in the success of any business. The right type of packaging can make all the difference when it comes to product protection, ease of transport, and customer satisfaction. In recent years, there has been a growing trend towards the use of pouches as a more convenient and eco-friendly option. Here are some of the main advantages of using these innovative pouches. Lightweight and Easy to Store Durable and Protective Preserve Product Freshness Flexibility and Customization Building Brand Recognition Customization Options Cost-Effective Packaging Brand Recognition Versatile Packaging Option Lightweight and Easy to Store Compared to traditional packaging materials like glass or metal, pouches are incredibly lightweight. This makes them ideal for businesses that need to transport and store products over long distances or in large quantities. Furthermore, because they require less material to produce, pouches are also a more cost-effective solution that reduces environmental impact. Durable and Protective The high-quality materials used to make pouches ensure that they are puncture-resistant and can withstand wear and tear during shipping or handling. For this reason, they are an ideal option for products that need extra protection, such as food, pharmaceuticals, and electronics. The water-resistant properties of these pouches also help prevent moisture damage to products. Preserve Product Freshness Pouches are known for their ability to keep products fresh for longer periods. Their airtight seal design helps prevent oxygen and moisture from entering the package, which is particularly important for products that are sensitive to air and moisture, such as food and pharmaceuticals. By preserving products, companies can reduce waste and increase customer satisfaction. Flexibility and Customization Poches come in various sizes, shapes, and designs, making them an ideal packaging option for companies that require different quantities and sizes. This flexibility allows businesses to tailor their packaging to specific product needs, ensuring that packaging is optimized and efficient. Customization options such as adding a resealable zipper or a spout can make them even more functional and convenient for customers. Building Brand Recognition Customizing pouches with a company’s logo or design can increase brand visibility and make products more recognizable to customers. This can help businesses build brand recognition and stand out in a crowded market. Customization Options Customization is one of the major benefits of using pouches for packaging, which can help a product stand out on store shelves and create a unique experience for customers. For instance, a company that sells coffee could use a it with a valve to keep the coffee fresh while allowing customers to smell the aroma. Similarly, a company that sells nuts could use it with a clear window to showcase the product’s natural appeal. Cost-Effective Packaging Pouches are also cost-effective. They require less material to produce than other types of packaging, which can reduce costs. Additionally, they are lightweight, which reduces shipping costs. Customizing the pouches means that companies can create packaging that fits their specific needs, reducing the likelihood of waste or excess packaging. Versatile Packaging Option Pouches are a versatile packaging option that can be used for various products. They are commonly used to package food products like snacks, pet food, and coffee, as well as non-food products like laundry detergent and personal care products. Their flexibility in size and shape makes them ideal for packaging different quantities and sizes. This type of packaging is often as a secondary packaging option. For example, a company that sells frozen food products could use it as an outer layer to protect the product during shipping and a smaller pouch inside for individual servings. If you are interested in custom pouches, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts

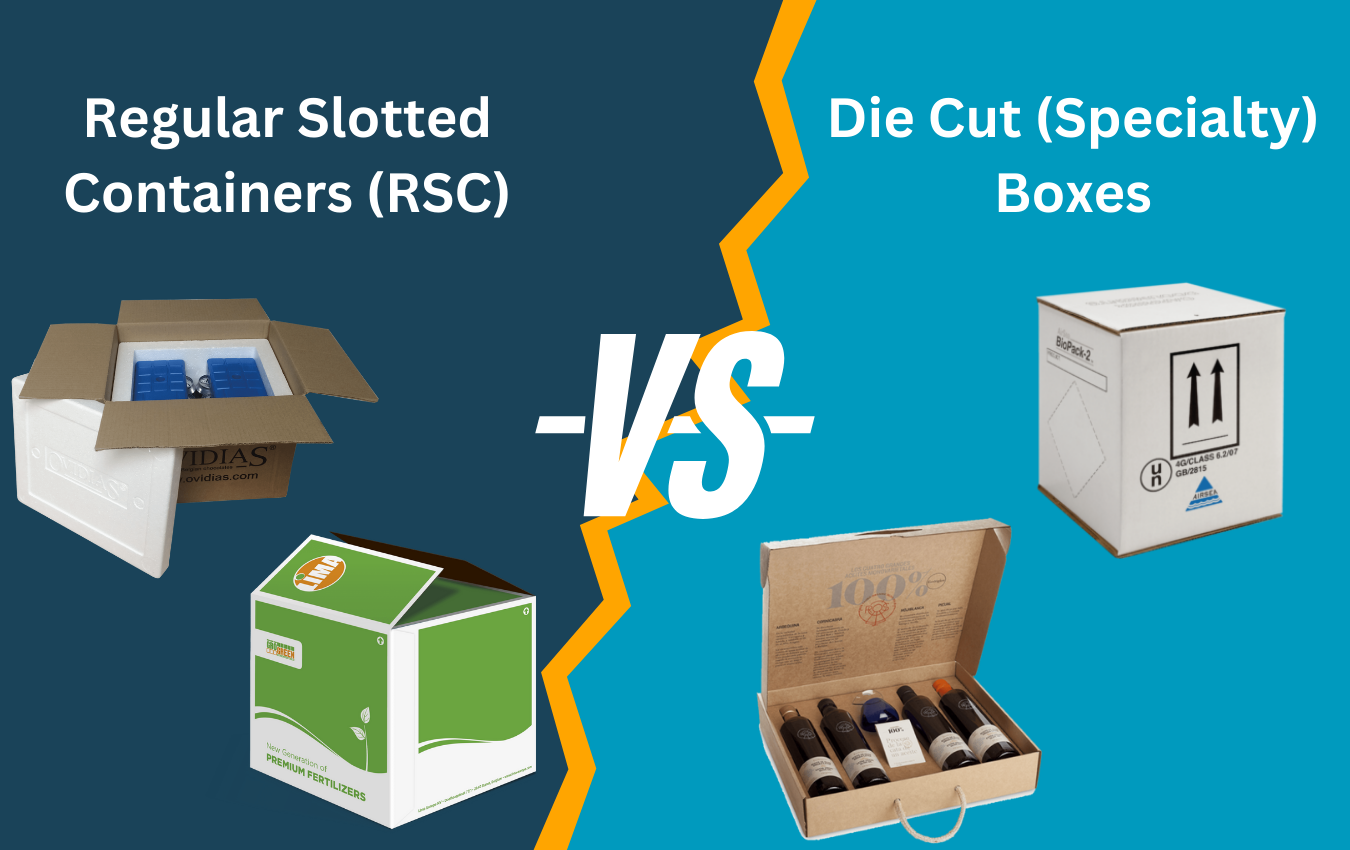

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer unique advantages for certain applications. Understanding when to stay with an RSC versus upgrading to a specialty style ensures buyers balance cost, performance, and presentation. When RSC Is Best Bulk Shipping: Strong compression strength makes RSC ideal for palletized loads. Low Cost: Efficient to manufacture with minimal board waste. Versatility: Works across industries from industrial to retail. Automation-Ready: Standardized design runs smoothly on case erectors and palletizers. When Specialty Boxes Are Better Full Overlap (FOL) Flaps overlap fully, reinforcing the top and bottom. Better for heavy products or shipments that need extra stacking strength. RETT Mailers Dust flaps and cherry locks eliminate tape, improving assembly speed. Ideal for e-commerce and branded unboxing experiences. Die-Cut Boxes Custom shapes and closures for product-specific fit. Useful when presentation and consumer experience are top priorities. Key Trade-Offs Feature RSC Box Specialty Box Styles Assembly Speed Slower (tape required) Faster (die-cut, self-locking) Stacking Strength High Variable (higher in FOL, lower in mailers) Branding Potential Basic Premium (better graphics and unboxing) Flexibility Universal Application-specific Buyer Takeaway Stick with RSC when cost, strength, and scalability matter most. Upgrade to FOL for heavy-duty industrial shipments. Choose RETT or die-cut mailers for e-commerce and premium branding. By evaluating your priorities — strength, speed or presentation — you can decide whether RSC remains the best fit or if specialty box styles deliver added value. References Fibre Box Association. (2023). Corrugated Box Styles and Applications. https://www.fibrebox.org Association of Independent Corrugated Converters (AICC). (2024). Corrugated Design and Performance. https://www.aiccbox.org Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce Display Foam Printing Protection Retail Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts