Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

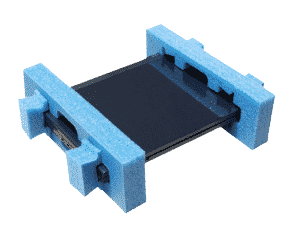

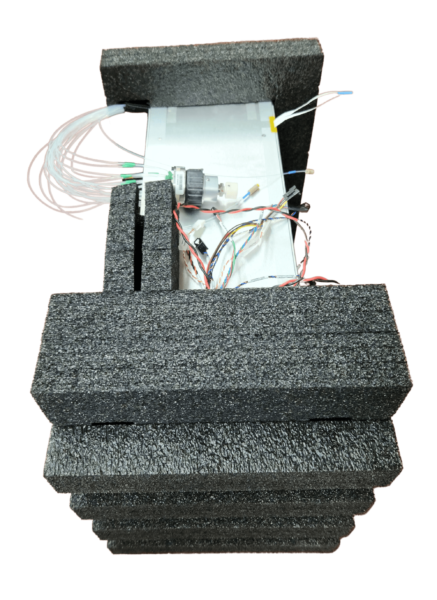

Packaging plays a crucial role in protecting products during transit and storage. Among the various materials used for packaging, polyethylene foam stands out as an excellent choice due to its unique combination of properties that make it ideal for cushioning and protecting a wide range of items. In this comprehensive guide, we will explore everything you need to know about polyethylene foam for packaging. What is Polyethylene Foam? Polyethylene foam is a lightweight material made from polyethylene, a type of plastic. It is characterized by its high resilience, flexibility, and excellent cushioning properties. Polyethylene foam is commonly used in various industries, including automotive, electronics and aerospace. Key Properties of Polyethylene Foam Polyethylene foam’s popularity in packaging is attributed to several key properties: Cushioning and Shock Absorption One of the primary reasons for using polyethylene foam in packaging is its exceptional cushioning and shock-absorbing capabilities. The structure of the foam allows it to compress and absorb impact energy, protecting delicate or fragile items from damage during handling and transportation. Lightweight Polyethylene foam is lightweight, making it an ideal choice for reducing shipping costs while still providing adequate protection. Its low weight-to-volume ratio is advantageous for both the manufacturer and the end consumer. Water Resistance Polyethylene foam is resistant to moisture and water, which helps protect products from water damage during transit or storage. This property is particularly important for items that are sensitive to moisture. Chemical Resistance Polyethylene foam is also resistant to many chemicals, oils, and solvents, making it suitable for packaging items that may come into contact with these substances. Durability Polyethylene foam is durable and long-lasting, ensuring that it can withstand the rigors of the packaging and shipping process. It does not easily tear, puncture, or break down over time. Thermal Insulation While not as efficient as some other insulating materials, polyethylene foam provides a degree of thermal insulation, helping to protect products from temperature fluctuations during transportation and storage. Types of Polyethylene Foam Polyethylene foam comes in various forms, each tailored to specific packaging needs: Plank Foam Plank foam is a solid sheet of polyethylene foam available in various thicknesses. It is often used for cushioning, interleaving, and lining packaging boxes. Roll Foam Roll foam is a continuous roll of polyethylene foam, which can be easily cut to the desired length. It is commonly used for wrapping and protecting fragile items. Die-Cut Foam Die-cut foam refers to polyethylene foam sheets that have been cut into specific shapes or profiles to fit the contours of a product precisely. This customized approach provides optimal protection for irregularly shaped items. Anti-Static Foam For packaging sensitive electronic components, anti-static polyethylene foam is available. It prevents electrostatic discharge (ESD) that can damage sensitive electronics. Common Applications of Polyethylene Foam in Packaging Polyethylene foam finds applications in a wide range of industries and packaging scenarios, including: Electronics Packaging Polyethylene foam is commonly used to protect electronic components, such as circuit boards, computer equipment, and delicate sensors, from shock and ESD during transportation. Automotive Packaging In the automotive industry, polyethylene foam is used to protect fragile automotive parts, prevent damage to painted surfaces, and reduce noise and vibration during transit. Medical Equipment Packaging Sensitive medical equipment, instruments, and devices are often packaged using polyethylene foam to ensure they reach their destination in pristine condition. Glassware and Dishware Packaging Fragile glassware, ceramics, and dishware benefit from polyethylene foam’s cushioning properties, preventing breakage and chipping. Furniture Packaging Polyethylene foam is used to protect furniture pieces like tables, chairs, and glass tabletops from scratches and damage during shipping. Aerospace Packaging In the aerospace industry, where precision and safety are paramount, polyethylene foam is used to protect critical components and equipment during transportation and storage. Choosing the Right Polyethylene Foam for Your Packaging Needs Selecting the appropriate polyethylene foam for your packaging requirements is crucial. Consider the following factors: Thickness Choose the foam thickness based on the fragility of the item you’re packaging. Thicker foam provides better cushioning for delicate items. Density The foam’s density affects its compression and cushioning abilities. Higher-density foam offers greater protection but may be heavier and more expensive. Type Select the right type of polyethylene foam (plank, roll, die-cut, or anti-static) depending on your packaging needs and the nature of the items you’re shipping. Customization For irregularly shaped items or unique packaging requirements, consider custom die-cut foam for a tailored solution. If you are interested in polyethylene foam, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Polyethylene (PE) Foam Facebook Twitter LinkedIn Pinterest Relevant Posts

Polypropylene, often referred to as PP plastic, is the second most widely used plastic globally, praised for its remarkable durability, strength, and resistance to various environmental factors. This thermoplastic polymer is behind the resilience of many items in our daily lives, from children’s toys that withstand rough play to the reliable lids on your shampoo bottles that endure frequent use. Properties of PP Plastic Durability and Robustness: PP is characterized by its ability to resist wear and tear, making it ideal for high-use products like automotive parts and consumer goods. Chemical Resistance: PP does not react with a wide range of chemicals, which makes it suitable for containers and pallets in chemical handling applications. Biological Resistance: It does not degrade or mold easily, resisting damage from biological elements such as bacteria and fungi, enhancing its utility in medical and food applications. Water Resistance: Its impermeability makes it essential for items that must withstand moisture, including medical devices and lab equipment. Fatigue Resistance: PP maintains its shape after bending or twisting, exemplified by its use in living hinges, such as those found on shampoo bottle lids. High Melting Point: With a melting point that allows it to withstand higher temperatures, PP is perfect for kitchenware and food appliances that undergo heat exposure. Electrical Insulation: Its resistance to electricity makes it a primary choice for electronic components. Cost-Effectiveness and Recyclability: PP is not only affordable but also fully recyclable, supporting environmental sustainability by reducing landfill waste. Applications of Polypropylene in Various Industries Packaging Solutions: PP’s flexibility and low cost make it a popular choice for various packaging needs, replacing traditional materials like paper and cellophane. It is extensively used in manufacturing containers such as pallets, bottles, yogurt containers, and food packaging products. Automotive Components: Due to its durability and resistance properties, PP is frequently utilized in the automotive industry for parts such as car batteries, bumpers, interior panels, and cladding. Medical Industry: PP’s resistance to rigorous sterilization makes it indispensable in medical applications. It is used for constructing medical devices and packaging systems for pharmaceutical products. Consumer Goods: From toys that must endure frequent handling to household items like rugs and kitchen utensils, PP is a staple material in the consumer goods sector. Material Handling: PP is often the material of choice for making durable plastic pallets and other material handling equipment, thanks to its robustness and resilience. For more information on polypropylene packaging solutions or to discuss your specific needs, please contact Brown Packaging. We are dedicated to providing high-quality, sustainable packaging solutions tailored to your requirements. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

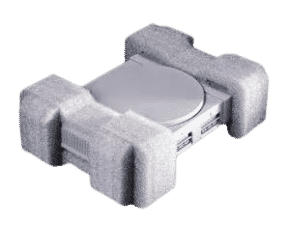

Packaging is a crucial component of product safety and marketing. Over the years, innovative materials have surfaced to enhance packaging capabilities, with one of the most effective being poly lamination foam. This versatile material, extensively used in the packaging industry, delivers unparalleled protection while offering significant cost benefits. In this comprehensive guide, we will delve deep into the world of poly lamination foam, exploring its unique properties, uses, and benefits. Poly Lamination Foam: An Introduction Let’s begin by breaking down what poly lamination foam is and how it is created. Polyethylene Foam: This is a foam’s structure consists of encapsulated bubbles that provide resilience, strength, and excellent shock absorption. Lamination: In this process, a protective layer is adhered to the foam, enhancing its durability, aesthetic appeal, and resistance to elements like moisture and dirt. Together, poly lamination foam offers a high-performance packaging solution, ensuring that products reach their destination in the best possible condition. The Strengths of Poly Lamination Foam Poly lamination foam offers numerous strengths that make it a preferred choice for packaging solutions. Durability: Thanks to the lamination process, this material is highly resistant to tearing, puncturing, and general wear-and-tear. It can withstand multiple impacts without compromising its integrity, making it ideal for protecting delicate or valuable goods. Moisture Resistance: Poly lamination foam is impervious to water, providing an excellent barrier against moisture and humidity. This feature makes it an excellent choice for products that are sensitive to such conditions. Lightweight: Despite its robust protection, poly lamination foam is incredibly lightweight, contributing to reduced shipping costs. Versatility: Poly lamination foam can be cut, shaped, and molded to fit a wide variety of products, making it a versatile choice for all types of packaging needs. Poly Lamination Foam in Various Industries With its myriad of benefits, poly lamination foam has found extensive use across various industries. Electronics: With electronics becoming more intricate and sensitive, they require robust packaging solutions. Poly lamination foam offers superior protection against shock, vibration, and static electricity, ensuring safe transport of these delicate items. Medical: In the healthcare industry, the safety of medical devices, pharmaceuticals, and diagnostic equipment is paramount. Poly lamination foam’s protective qualities make it ideal for this sector. Automotive: Automotive parts can be heavy, bulky, and delicate. Poly lamination foam is capable of providing the cushioning and protection needed during their transportation. Cosmetics: The cosmetics industry often needs to transport delicate bottles and containers. The foam’s ability to be customized allows for a perfect fit, reducing the risk of breakage. If you are interested in poly lamination foam for your packaging applications, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Foam Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right temperature during storage and transportation is essential. In this blog, we’ll explore various strategies and best practices to help you protect your packaging against temperature fluctuations effectively. Understanding the Risks Before we delve into protective measures, it’s crucial to understand the potential risks associated with temperature fluctuations: Product Quality: Fluctuating temperatures can alter the quality, texture, and taste of products, rendering them unsellable or unsafe for consumption. Chemical Reactions: Some products, particularly chemicals and pharmaceuticals, can undergo chemical reactions when exposed to temperature extremes, resulting in changes in composition or efficacy. Packaging Integrity: Extreme temperatures can weaken packaging materials, making them more susceptible to tears, punctures, or structural damage. Protective Measures To safeguard your packaging against temperature fluctuations, consider implementing the following protective measures: Temperature-Controlled Packaging: Use temperature-controlled packaging solutions, such as insulated boxes, coolers, or heated containers, depending on the specific temperature requirements of your products. Insulated Packaging Materials: Choose packaging materials with insulating properties. Foam, bubble wrap, or insulated liners can help maintain stable temperatures within the package. Phase-Change Materials: Incorporate phase-change materials or gel packs into your packaging. These materials can absorb or release heat to help regulate the temperature inside the package. Seal Integrity: Ensure that packaging seals are strong and airtight. Regular quality control checks should verify that no gaps or defects exist in the sealing process to prevent temperature infiltration. Packaging Design Considerations: Design packaging with temperature resistance in mind. Use materials that can withstand temperature extremes, and consider multi-layer structures for added insulation. Quality Testing: Conduct rigorous testing to verify the effectiveness of your packaging in maintaining temperature stability. Use temperature testing chambers to simulate real-world conditions. Temperature Monitoring Devices: Incorporate temperature monitoring devices, such as data loggers or indicators, into your packaging. These devices record temperature data during transit, providing insight into temperature fluctuations. Controlled Storage Facilities: Store products in temperature-controlled environments before and after packaging. Warehouses and storage areas should be equipped with adequate ventilation, heating, and cooling systems. Shipping Route Planning: Select shipping routes and carriers that prioritize temperature control and offer refrigerated or climate-controlled transportation options. Regulatory Compliance: Adhere to industry-specific and regulatory standards for temperature-sensitive products. Compliance ensures that your products meet safety and quality requirements. Vigilance and Continuous Improvement Protecting your packaging against temperature fluctuations is an ongoing effort. Continuously assess your packaging solutions and gather feedback from transportation partners to identify any weaknesses or areas for improvement. Make necessary adjustments to enhance temperature resilience and ensure that your products arrive at their destination in optimal condition. By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of temperature-related damage to your products, enhance their overall quality and safety, and meet the specific temperature requirements of your industry. If you are interested in protection against temperature fluctuations for your packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Cold Chain Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Tariffs can create significant challenges for packaging buyers, affecting costs, supply chains, and sourcing strategies. While tariffs are designed to promote domestic production, they often introduce complexities that impact businesses relying on imported materials. With thoughtful planning and strategic actions, packaging buyers can minimize these impacts and maintain operational efficiency. Understanding the Impact of Tariffs on Packaging Tariffs impose additional taxes on imported goods, driving up the costs of raw materials and finished packaging products. For the packaging industry, this includes commonly used materials such as corrugated cardboard, plastics, and metals. These added expenses often lead to higher procurement costs, supply chain adjustments, and increased administrative burdens. Strategies to Limit the Impact of Tariffs Reevaluate Your Supply Chain The first step to reducing the impact of tariffs is gaining a clear understanding of your current supply chain. Knowing where your materials and packaging products originate helps identify risks and areas for improvement. Key Steps: Map out your supply chain to identify dependencies on imported goods. Identify tariff-affected materials and evaluate their contribution to your costs. Explore local or alternative suppliers to reduce reliance on imports. Strengthen Relationships with Domestic Suppliers With tariffs increasing the cost of imports, domestic sourcing becomes a more attractive option. Building strong partnerships with local suppliers can help secure reliable and affordable packaging. Actionable Tips: Establish long-term contracts to lock in pricing and secure priority access. Collaborate with domestic manufacturers to explore custom solutions tailored to your needs. Consider working with regional distributors for quicker lead times and reduced shipping costs. Diversify Your Supplier Base Relying heavily on one supplier or region can expose your business to greater risks when tariffs are introduced. Diversifying your supplier network provides flexibility and reduces vulnerability. Implementation Steps: Source from multiple domestic suppliers to mitigate potential shortages. Evaluate international suppliers in tariff-free regions for cost-effective alternatives. Work with packaging distributors who offer access to a variety of options. Optimize Packaging Design Innovative packaging design can help reduce material usage and overall costs, minimizing the financial impact of tariffs. Design Adjustments: Lightweighting: Use thinner or lighter materials to lower costs. Right-Sizing: Tailor box sizes to reduce material waste and shipping costs. Mono-Material Solutions: Simplify designs to use fewer or single types of materials. Explore Alternative Materials Switching to tariff-free or domestically sourced materials can provide significant savings. Examples: Transition from virgin paperboard to recycled corrugated materials. Use kraft paper or mailers as cost-effective alternatives to plastic-based packaging. Evaluate the feasibility of biodegradable or compostable materials that align with sustainability goals. Plan Ahead and Stockpile Strategically Tariffs often lead to increased lead times, especially as demand for domestic suppliers grows. Proactive planning ensures you’re prepared for potential disruptions. Practical Steps: Forecast demand to order packaging materials in advance of tariff changes. Stockpile critical materials with long shelf lives to avoid shortages. Develop an inventory management system to balance stock levels and avoid overstocking. Negotiate Pricing and Payment Terms Work with your suppliers to manage tariff-related cost increases effectively. Negotiation Tips: Request volume discounts for bulk orders. Negotiate extended payment terms to ease cash flow pressures. Explore opportunities for bundled services to reduce overall costs. Leverage Technology for Supply Chain Efficiency Investing in technology can improve decision-making and streamline procurement processes, helping mitigate the administrative burden of tariffs. Recommended Tools: Supply Chain Management Software: Monitor supplier performance and optimize sourcing strategies. Tariff Calculators: Assess the impact of tariffs on your materials and products. Inventory Management Systems: Improve forecasting accuracy and avoid last-minute purchases. Long-Term Benefits of Adapting to Tariffs While tariffs can create short-term challenges, they also encourage businesses to adopt resilient and innovative strategies. By optimizing supply chains, exploring sustainable options, and strengthening relationships with domestic suppliers, packaging buyers can position themselves for long-term success. Conclusion Tariffs on packaging can introduce complexities, but with proactive planning and strategic adjustments, their impact can be minimized. By reevaluating supply chains, optimizing packaging designs, diversifying suppliers, and leveraging technology, packaging buyers can navigate these changes effectively while maintaining operational efficiency. Taking these steps now can help businesses adapt to a changing landscape and thrive in a competitive market. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts