Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

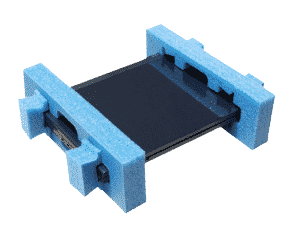

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

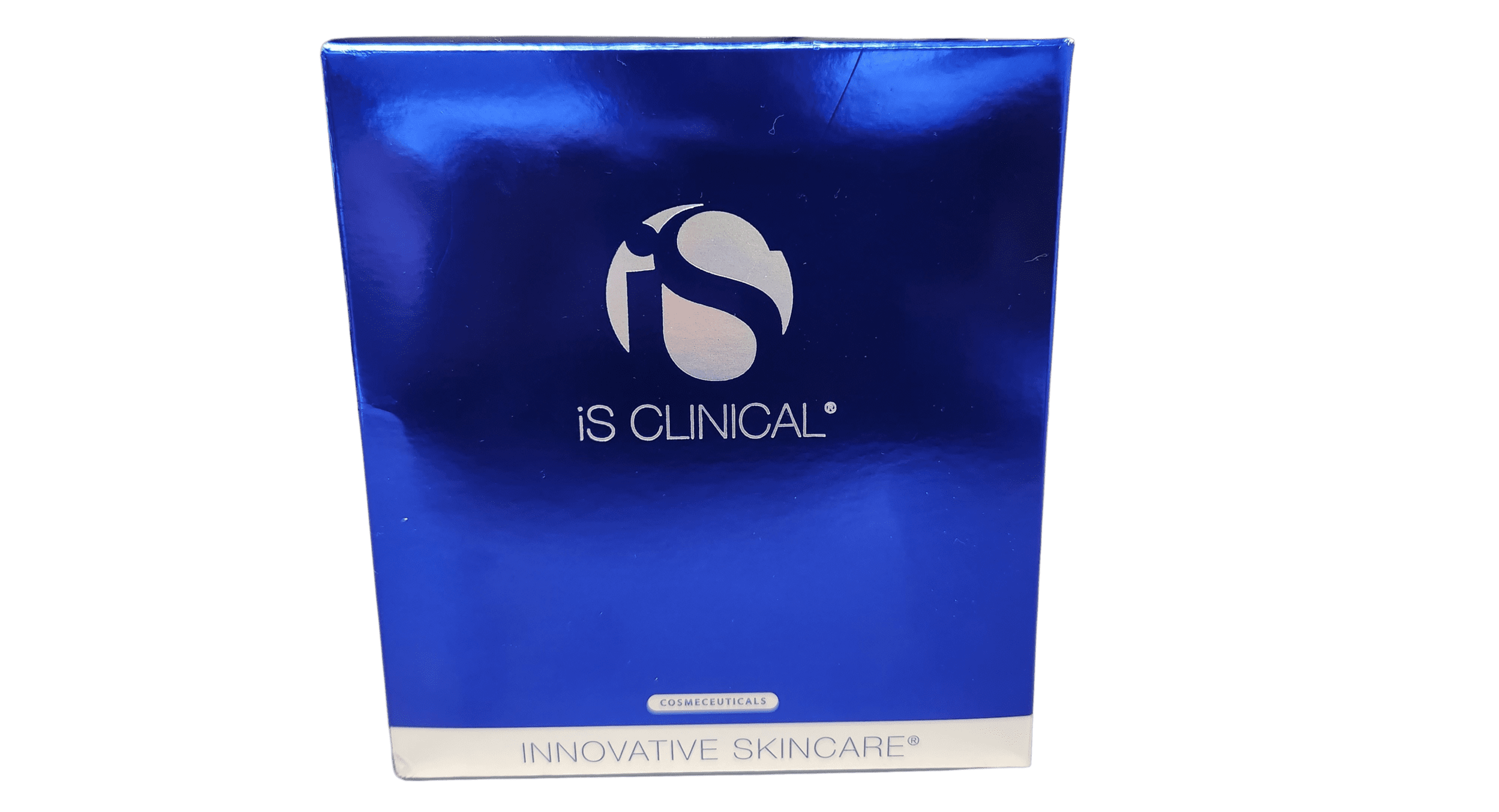

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

Designing a Full-Overlap (FOL) box tailored to your specific needs is a critical step in ensuring the safe and secure packaging of your products. FOL boxes are renowned for their strength and protection, making them ideal for shipping delicate, valuable, or heavy items. In this comprehensive buyer’s guide, we will walk you through the essential steps and considerations to design a Full-Overlap box that meets your packaging requirements. Step 1: Define Your Product Requirements Step 2: Box Dimensions and Sizing Step 3: Material Selection Step 4: Box Style and Closure Step 5: Customization and Branding Step 6: Testing and Prototyping Step 7: Eco-Friendly Considerations Step 8: Production and Ordering Step 9: Shipping and Handling Step 1: Define Your Product Requirements Product Type: Clearly identify the product you intend to package. Understand its dimensions, weight, fragility, and any unique characteristics. Quantity: Determine the quantity of products you need to package per box, as this affects the box’s size and capacity. Protection Needs: Assess the level of protection required. Consider whether your product needs cushioning, shock absorption, or additional support within the box. Step 2: Box Dimensions and Sizing Interior Dimensions: Calculate the interior dimensions of the box based on your product’s size and quantity. Ensure there is enough space to accommodate the product without excess room that can lead to movement during transit. Customization: Decide if you need a custom-sized box or if standard FOL box sizes are suitable for your product. Customization allows for a perfect fit, reducing the risk of damage during shipping. Step 3: Material Selection Corrugated Material: Choose the corrugated material that suits your packaging needs. Single-wall corrugated is suitable for lightweight items, while double-wall corrugated provides added strength and protection for heavier products. Flute Type: Select the flute type (e.g., A, B, C, or E flute) based on your product’s fragility and weight. Larger flute sizes offer better cushioning. Step 4: Box Style and Closure Full-Overlap (FOL) Design: Opt for the FOL box style, known for its overlapping flaps that enhance structural integrity and protection. Closure Method: Choose the closure method, such as adhesive tape, glue, or staples, that suits your packaging process and ensures a secure seal. Step 5: Customization and Branding Graphics and Branding: Consider adding custom graphics, branding, or product information to the box to enhance its visual appeal and promote your brand. Printing Options: Decide between flexographic or lithographic printing methods based on your desired print quality and budget. Step 6: Testing and Prototyping Prototyping: Before committing to a large production run, create a prototype of your FOL box to test its fit and functionality. Quality Control: Establish quality control measures to ensure that each box meets your specifications and provides the necessary protection. Step 7: Eco-Friendly Considerations Recyclability: Choose eco-friendly corrugated materials that are easily recyclable, supporting sustainability initiatives. Ink and Coating: Select water-based inks and coatings for environmentally responsible printing options. Step 8: Production and Ordering Vendor Selection: Choose a reputable corrugated box manufacturer with experience in producing FOL boxes to ensure quality and reliability. Order Quantity: Determine the quantity of FOL boxes you need, considering production lead times and storage space. Step 9: Shipping and Handling Storage: Store your FOL boxes in a dry, cool, and clean environment to prevent damage before use. Handling Instructions: Provide handling instructions for your shipping and warehouse teams to ensure that the FOL boxes are used correctly.Top of Form If you are interested full overlap (FOL) corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Full Overlap Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Polyethylene terephthalate, commonly abbreviated, stands out in the packaging industry for its versatility and environmental friendliness. Recognized as the most widely recycled plastic worldwide, this polymer combines clarity, durability, and lightweight properties, making it ideal for a diverse range of packaging applications. Understanding Polymer Packaging What Is This Material? This polymer is known for its robustness and chemical inertness. It is inherently clear, allowing for excellent visibility of the product inside, which is crucial for consumer goods. Its strength ensures it can handle the rigors of transport and retail environments without compromising the product’s integrity. Additionally, it is lightweight, reducing transportation costs and lessening the environmental impact. Eco-Friendly Aspects A significant advantage of this material is its sustainability. It can be recycled repeatedly without degradation in quality, contributing to a circular economy. Innovations in recycled content underscore the material’s role in promoting environmental sustainability. Benefits of Using This Polymer for Packaging Design Flexibility: The versatility allows it to be molded into various shapes and sizes—from standard rectangles to intricate designs. This flexibility enables brands to create unique packaging that stands out on the shelves and communicates the product’s message effectively. Moisture Resistance: Unlike materials such as cardboard, it retains its shape and integrity even in moist environments, protecting the product and maintaining the packaging’s aesthetic appeal. Lightweight and Durable: Despite its light weight, it is remarkably strong, providing excellent protection for the contents while reducing the overall weight of the package. This strength-to-weight ratio makes it an economical choice for manufacturers and distributors. Food Safety: The food-safe properties make it an ideal choice for food and beverage packaging, ensuring that products remain safe and uncontaminated from production to consumption. Applications of Polymer Packaging Its attributes make it suitable for a wide array of products: Food and Beverage: From bottled beverages to blister packaging for perishables, its clarity and safety are highly valued. Pharmaceuticals: It provides secure, tamper-evident packaging for medicines, ensuring product integrity and patient safety. Cosmetics and Personal Care: The aesthetic appeal and durability make it suitable for high-end cosmetics and everyday personal care products. Electronics and Gift Packs: The strong yet lightweight nature protects electronics and gifts while allowing for attractive, custom designs. Household Items and Toys: Its robustness makes it suitable for packaging various household goods and children’s toys, ensuring safety and durability. Why Choose Polymer Packaging? Choosing this material for your packaging needs means investing in a material that offers superior performance in both protection and presentation. It supports innovative design possibilities that can enhance brand perception and consumer attraction. Additionally, its environmental credentials help companies meet sustainability goals, an increasingly important factor in consumer decisions. For businesses looking to leverage these benefits, partnering with a provider like Brown Packaging, skilled in designing and producing high-quality solutions, is crucial. Such partnerships enable businesses to fully utilize the advantages of this material, from conceptual design to the final product. Whether for simple storage solutions or complex marketing displays, Brown Packaging offers a clear, sustainable choice that meets both practical and aesthetic needs effectively. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of packaging, making a memorable impression is crucial. Packaging not only protects and delivers products but also serves as a powerful branding and marketing tool. Foil stamping, a decorative technique, has gained popularity as a means to add elegance, sophistication, and visual appeal to packaging. In this detailed blog, we will explore what foil stamping is in packaging and how it can elevate your brand’s image and make a lasting impact on customers. What is Foil Stamping? Foil stamping, also known as foil printing, mainly used in hot stamping, is a specialized printing process used to apply metallic or pigmented foil onto various materials, including paper, cardboard, plastics, and more. This process involves the application of heat and pressure to transfer the foil material onto the packaging surface. The result is a brilliant and eye-catching design that stands out from traditional printing methods. How Foil Stamping Works The foil stamping process consists of several key steps: Design Preparation: The first step involves creating a custom design or selecting pre-made foil stamping patterns or templates. This design will be transferred onto the packaging material. Die Creation: A metal die is fabricated based on the chosen design. The die is heated during the stamping process and serves as a mold for transferring the foil. Foil Feeding: The foil roll is placed above the packaging material, and a heat-activated adhesive is applied to the area where the foil will adhere. Stamping Process: The heated metal die is pressed onto the packaging material, transferring the foil onto the adhesive-coated area. The pressure and heat cause the foil to bond with the packaging surface, leaving the desired design in a brilliant metallic or pigmented finish. Cooling and Removal: After the foil is applied, it is allowed to cool, which sets it firmly onto the packaging material. Once cooled, any excess foil is removed, leaving only the stamped design. Benefits of Foil Stamping in Packaging Foil stamping offers a multitude of benefits that make it an attractive choice for packaging enhancement: Visual Appeal: Foil stamping adds a luxurious and eye-catching element to packaging, making it stand out on the shelf or in the hands of customers. Elegance and Sophistication: The reflective and shimmering qualities of foil create an impression of elegance, making it suitable for high-end and luxury products. Customization: Foil stamping allows for customization with various foil colors, including metallic, matte, and holographic options, enabling brands to tailor the design to their unique identity. Durability: Foil-stamped designs are resilient and resistant to fading, ensuring that the packaging maintains its visual appeal over time. Branding and Brand Recognition: Foil-stamped logos and branding elements increase brand recognition and help customers associate the packaging with the brand. Versatility: Foil stamping can be used on a wide range of packaging materials, such as boxes, labels, bags, and more, making it a versatile choice. Applications of Foil Stamping in Packaging Foil stamping can be applied to various packaging types and industries: Cosmetics: Foil stamping is commonly used for high-end cosmetic packaging to convey luxury and quality. Food and Beverages: Premium food and beverage products often feature foil-stamped labels or packaging to communicate exclusivity. Pharmaceuticals: Foil stamping on pharmaceutical packaging can enhance product visibility and compliance. Retail Packaging: Foil-stamped logos and branding elements on retail packaging create an upscale and memorable shopping experience. Event and Wedding Invitations: Foil-stamped invitations and stationery add a touch of elegance and sophistication to special occasions. Conclusion Foil stamping is a remarkable decorative technique that can transform ordinary packaging into extraordinary masterpieces. With its ability to add visual appeal, elegance, and brand recognition, foil stamping is a valuable tool for businesses aiming to make a lasting impression on customers and stand out in a competitive market. Whether used for branding, customization, or enhancing the perceived value of products, foil stamping is a versatile and impactful choice in the world of packaging. If you are interested in packaging with foil stamping, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

There’s a common saying in the marketing world: “It’s not what you sell that matters as much as how you sell it.” While the quality and function of your product is undoubtedly essential, the packaging it arrives in and its ability to ensure the product’s safety plays a critical role in shaping the customer’s perception and overall experience. In this blog, we will delve deep into understanding how protective packaging can impact customer experience, providing valuable insights for businesses in all sectors. The Role of Protective Packaging Before diving into the impact of protective packaging, it’s important to first understand its role. This includes any material used to protect, immobilize, conceal, and even provide environmental protection to the product. Depending on the nature and fragility of the product, protective packaging can range from bubble wraps, foam inserts, to air pillows, and more. First Impressions Matter: Unboxing Experience We live in an era where the ‘unboxing experience’ can make or break a customer’s impression of a brand. The moment when a customer opens their package is a unique touchpoint that can elicit emotions of anticipation and excitement. If a product is received in excellent condition, with high-quality protective packaging, it sends a message to the customer that the brand values their purchase and cares about their experience. On the other hand, a poor unboxing experience – if the product is damaged due to insufficient protective packaging – can instantly leave a negative impression, and in worst cases, result in product returns and negative reviews. It’s important to remember that these customer reviews, shared online, can significantly influence the decision-making process of potential future customers. Impact on Customer Trust and Brand Image Another key aspect of the customer experience revolves around trust. Consumers trust brands to deliver their purchases safely, and the use of appropriate protective packaging is a key element in building this trust. When customers repeatedly receive their purchases in perfect condition, it not only reinforces their trust in your brand but also improves your brand image. High-quality packaging can reflect a company’s professionalism and commitment to customer satisfaction, significantly enhancing the perceived value of the brand. Environmental Impact and Consumer Perception As environmental concerns increasingly shape consumer behavior, brands are now facing the pressure to minimize their environmental footprint. The choice of protective packaging plays a big part in this. Consumers are more aware than ever and often prefer eco-friendly packaging solutions. Offering sustainable protective packaging options can thus positively influence your brand image and appeal to a growing environmentally conscious audience. This can not only differentiate your brand in a competitive market but also inspire customer loyalty. The Value of Customization Customization in protective packaging can significantly enhance the customer experience. Custom-cut foam inserts or designed air cushions, for instance, not only provide excellent product protection but also offer an unboxing experience that feels personalized and premium. This detail can also indicate a higher level of care taken by the company to protect the product, further enhancing the customer’s perception of the brand. Cost Factor: Balancing Protection and Affordability While it’s clear that protective packaging is a worthy investment, businesses must balance the cost. Over-packaging a product can lead to unnecessary costs and even customer frustration, while under-packaging can risk product damage and customer dissatisfaction. Finding the right balance is key to ensuring customer satisfaction while maintaining business profitability. Conclusion: A Pillar of the Customer Experience In conclusion, protective packaging plays a substantial role in determining the customer experience. From the unboxing moment, building customer trust, enhancing brand image, to aligning with environmental values, every aspect of protective packaging can have far-reaching impacts on how a customer perceives a brand and its products. The unboxing experience sets the tone for the entire customer journey, and the use of high-quality protective packaging demonstrates a brand’s commitment to customer satisfaction. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of sealing and closure not only ensures the safety and security of the contents but also can enhance ease of use, storage, and even branding. This blog post explores the different types of sealing and closure methods available for corrugated boxes, helping businesses choose the best option for their specific needs. Understanding the Importance of Proper Sealing and Closure Before delving into the types, it’s crucial to understand why sealing and closure matter. The right closure method can protect the contents from damage, theft, or contamination, while also providing an additional layer of branding through custom tapes or seals. Tape Closure One of the most common methods of sealing corrugated boxes is using tape. This method is versatile and cost-effective, suitable for a wide range of applications. Pressure-Sensitive Tape: Easy to apply, available in various widths and strengths, and ideal for lightweight to medium-weight boxes. Water-Activated Tape (WAT): Forms a strong bond with the corrugated box, offering superior security, and is excellent for heavier packages. Reinforced Water-Activated Tape: Best for heavy-duty applications, providing extra strength and security. Staple Closure Stapling is a traditional method of closing corrugated boxes, often used for heavy or industrial items. Manual Stapling: Suitable for small-scale operations or where additional security is needed. Pneumatic Stapling: Used in larger operations for efficiency and consistency in sealing. Glue Closure Adhesive or glue is another popular method, especially in automated packaging lines. Hot Melt Adhesive: Quick to apply and set, providing a strong and durable seal. Cold Glue Adhesive: Requires more time to set but offers a strong bond and is suitable for boxes that require refrigeration. Self-Locking Tabs and Slots For consumer-facing products, self-locking tabs and slots offer an appealing and tool-free option. Tab Lock: Simple to use, providing a secure closure without additional materials. Slot Lock: Offers added security as tabs lock into slots, making the box more tamper-resistant. Velcro or Hook-and-Loop Closures For reusable box designs, Velcro or hook-and-loop closures are ideal. Easy Open and Close: Allows for multiple uses, ideal for sample kits or storage boxes. Customizable: Can be designed in various shapes and sizes to suit specific packaging needs. Strapping or Banding Strapping or banding is used for heavy-duty applications or for bundling multiple boxes together. Metal Strapping: Offers the highest strength, ideal for heavy industrial goods. Polyester or Polypropylene Strapping: More flexible than metal, suitable for a wide range of applications. Sealing with Labels or Stickers Custom labels or stickers can double as a sealing method, particularly for light packages or as an additional security seal. Branding Opportunity: Custom labels provide a platform for branding and product information. Tamper-Evident Seals: Enhance security by indicating if the box has been opened. Conclusion The choice of sealing and closure method for corrugated boxes depends on several factors, including the weight and nature of the contents, the shipping and handling process, the need for security, and the desired customer experience. By selecting the appropriate sealing and closure method, businesses can ensure their products are well-protected and arrive at their destination in the best possible condition. Moreover, creative and practical sealing solutions can enhance brand recognition and provide an additional touchpoint for customer engagement. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts